Using AI to correct additive manufacturing errors in real time

Researchers at the Massachusetts Institute of Technology (MIT) trained a machine learning model to monitor and adjust the 3D printing process to correct errors in real time.

New materials that can be used for 3D printing are constantly being developed, but figuring out how to print with them can be a complex and costly puzzle. Typically, operators must use manual trial and error, potentially running thousands of prints, to determine the ideal parameters to print new materials consistently and efficiently.

Researchers at MIT have used artificial intelligence to streamline the process. Scientists at the agency have developed a new machine learning system that uses computer vision to observe the manufacturing process and can correct errors in how materials are handled in real time.

They used simulations to teach a neural network how to adjust printing parameters to minimize errors, and then applied the controller to a real 3D printer. The new system can print objects more accurately than other existing 3D printing controllers.

This work avoids the expensive process of printing thousands or millions of real objects to train neural networks. It could make it easier for engineers to integrate new materials into their 3D printed products, which could help them develop products with special electrical or chemical properties. It also helps technicians make adjustments to the printing process when materials or environmental conditions change unexpectedly.

"This project is really the first demonstration of building a manufacturing system that uses machine learning to learn complex control strategies," said Wojciech Matusik, professor of electrical engineering and computer science at MIT who led the project. If you have smarter manufacturing equipment that can adapt in real time to changing circumstances in the workplace to increase output or system accuracy, you can get more value out of your machines."

Pick Parameters

Determining the ideal parameters for a digital manufacturing process can be one of the most expensive parts of the process, as it requires a lot of trial and error. Once the technician finds a combination that works well, these parameters only apply to a specific situation. They have little data on whether the materials behave in other environments, on different hardware, or on new batches of materials that exhibit different properties.

Using machine learning systems is also full of challenges. First, the researchers need to measure what is happening on the 3D printer in real time.

To do this, the researchers developed a machine vision system that uses two cameras aimed at the 3D printer’s nozzle. The system shines light onto the material as it is being deposited and calculates the thickness of the material based on the amount of light that passes through. "You can think of the visual system as a pair of eyes observing this process in real time," Foshey said.

The controller will then process the images it receives from the vision system and adjust the feed rate and orientation of the printer based on any errors it sees.

But training a neural network-based controller to understand this manufacturing process is data-intensive and requires millions of prints. So the researchers built a simulator.

Successful Simulation

To better train the controller, they used a process called reinforcement learning, in which The model learns through trial and error and is rewarded. The task of the model is to select printing parameters in order to create specific objects in the simulation environment. After showing the expected output, the model is rewarded when it selects parameters that minimize the error between its print and the expected result.

In this case, "error" means that the model either allocated too much material, placing it in areas that should remain open, or did not allocate enough material, leaving The open spots below should be filled. As the model performs more simulated prints, it updates its control strategy to maximize rewards, becoming increasingly accurate.

However, the real world is messier than the simulation. In practice, conditions often vary due to small changes or noise in the printing process. So the researchers created a numerical model that approximates the noise from a 3D printer. They used this model to add noise to their simulations, producing more realistic results.

"We found it interesting that by implementing this noise model we were able to convert controls trained purely in simulation The strategy is transferred to the hardware without any physical experiments for training," Foshey said, "and afterwards, we don't need to do any fine-tuning on the actual device."

When testing the controller It prints objects more accurately than any other control method previously evaluated. It performs particularly well in infill printing, which is printing the inside of an object. Some other controllers deposited so much material that the printed objects were raised, but the researchers' controller adjusted the printing path so that the objects remained level.

Their control strategy can even understand how the material spreads after deposition and adjust parameters accordingly.

auto-adjust

"We are also able to design control strategies that can dynamically control different types of materials. So if you have a manufacturing process on site and you want to change materials, you don't have to re-validate the manufacturing process. You can just load the new material, The controller will automatically adjust," Foshey said.

Now that they have demonstrated the effectiveness of this technique for 3D printing, the researchers hope to develop controllers for other manufacturing processes. They also want to see how the method can be modified to handle multiple layers of materials or printing multiple materials at the same time. Additionally, their method assumes each material has a fixed viscosity, but future iterations could use AI to identify and adjust viscosity in real time.

MIT has a long history in additive manufacturing and has spawned several major 3D printing companies, such as Desktop Metal and VulcanForms. This work was supported in part by the FWF Lise-Meitner Program, a European Research Council Starting Grant, and the National Science Foundation.

The above is the detailed content of Using AI to correct additive manufacturing errors in real time. For more information, please follow other related articles on the PHP Chinese website!

Does Hugging Face's 7B Model OlympicCoder Beat Claude 3.7?Apr 23, 2025 am 11:49 AM

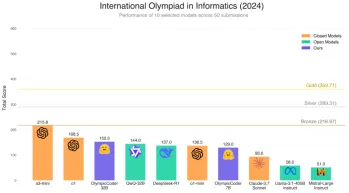

Does Hugging Face's 7B Model OlympicCoder Beat Claude 3.7?Apr 23, 2025 am 11:49 AMHugging Face's OlympicCoder-7B: A Powerful Open-Source Code Reasoning Model The race to develop superior code-focused language models is intensifying, and Hugging Face has joined the competition with a formidable contender: OlympicCoder-7B, a product

4 New Gemini Features You Can't Afford to MissApr 23, 2025 am 11:48 AM

4 New Gemini Features You Can't Afford to MissApr 23, 2025 am 11:48 AMHow many of you have wished AI could do more than just answer questions? I know I have, and as of late, I’m amazed by how it’s transforming. AI chatbots aren’t just about chatting anymore, they’re about creating, researchin

Camunda Writes New Score For Agentic AI OrchestrationApr 23, 2025 am 11:46 AM

Camunda Writes New Score For Agentic AI OrchestrationApr 23, 2025 am 11:46 AMAs smart AI begins to be integrated into all levels of enterprise software platforms and applications (we must emphasize that there are both powerful core tools and some less reliable simulation tools), we need a new set of infrastructure capabilities to manage these agents. Camunda, a process orchestration company based in Berlin, Germany, believes it can help smart AI play its due role and align with accurate business goals and rules in the new digital workplace. The company currently offers intelligent orchestration capabilities designed to help organizations model, deploy and manage AI agents. From a practical software engineering perspective, what does this mean? The integration of certainty and non-deterministic processes The company said the key is to allow users (usually data scientists, software)

Is There Value In A Curated Enterprise AI Experience?Apr 23, 2025 am 11:45 AM

Is There Value In A Curated Enterprise AI Experience?Apr 23, 2025 am 11:45 AMAttending Google Cloud Next '25, I was keen to see how Google would distinguish its AI offerings. Recent announcements regarding Agentspace (discussed here) and the Customer Experience Suite (discussed here) were promising, emphasizing business valu

How to Find the Best Multilingual Embedding Model for Your RAG?Apr 23, 2025 am 11:44 AM

How to Find the Best Multilingual Embedding Model for Your RAG?Apr 23, 2025 am 11:44 AMSelecting the Optimal Multilingual Embedding Model for Your Retrieval Augmented Generation (RAG) System In today's interconnected world, building effective multilingual AI systems is paramount. Robust multilingual embedding models are crucial for Re

Musk: Robotaxis In Austin Need Intervention Every 10,000 MilesApr 23, 2025 am 11:42 AM

Musk: Robotaxis In Austin Need Intervention Every 10,000 MilesApr 23, 2025 am 11:42 AMTesla's Austin Robotaxi Launch: A Closer Look at Musk's Claims Elon Musk recently announced Tesla's upcoming robotaxi launch in Austin, Texas, initially deploying a small fleet of 10-20 vehicles for safety reasons, with plans for rapid expansion. H

AI's Shocking Pivot: From Work Tool To Digital Therapist And Life CoachApr 23, 2025 am 11:41 AM

AI's Shocking Pivot: From Work Tool To Digital Therapist And Life CoachApr 23, 2025 am 11:41 AMThe way artificial intelligence is applied may be unexpected. Initially, many of us might think it was mainly used for creative and technical tasks, such as writing code and creating content. However, a recent survey reported by Harvard Business Review shows that this is not the case. Most users seek artificial intelligence not just for work, but for support, organization, and even friendship! The report said that the first of AI application cases is treatment and companionship. This shows that its 24/7 availability and the ability to provide anonymous, honest advice and feedback are of great value. On the other hand, marketing tasks (such as writing a blog, creating social media posts, or advertising copy) rank much lower on the popular use list. Why is this? Let's see the results of the research and how it continues to be

Companies Race Toward AI Agent AdoptionApr 23, 2025 am 11:40 AM

Companies Race Toward AI Agent AdoptionApr 23, 2025 am 11:40 AMThe rise of AI agents is transforming the business landscape. Compared to the cloud revolution, the impact of AI agents is predicted to be exponentially greater, promising to revolutionize knowledge work. The ability to simulate human decision-maki

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.

SublimeText3 Mac version

God-level code editing software (SublimeText3)