Is robotic IoT the future of manufacturing?

Real-life examples of robotic IoT

The robotic IoT can come in many forms.

Collaborative robot

A collaborative robot (often called a cobot) is an industrial robot that operates alongside humans. Unlike traditional colleagues, it's safe to work next to them. Most use IoT sensors to determine the location of workers. If someone gets too close, they'll stop what they're doing.

Mobile Robot

A mobile robot can move around, so it is usually much smaller than most industrial types. Many people follow a predetermined path. They're often used in distribution centers and warehouses so employees don't have to lift, bend or squat as often - they keep people in better shape and go faster.

Many mobile robots use IoT technology to coordinate so that they don't bump into anything. Because their sensors allow them to react to their surroundings in real time, they can decide where to go instead of being stuck on a preset path—which helps when obstacles suddenly appear.

Network Robot

Network Robot is a collection of IoT machines that operate as a whole. They all operate on the same network, exchanging information and coordinating actions. If someone reports a delay or unusual event, others will know immediately.

Cognitive Robots

Cognitive IoT leverages technologies such as artificial intelligence, cloud computing, and sensors to help devices understand their surroundings and develop logic skills over time . When combined with robotics, the result is a machine capable of reasoning.

In practice, cognitive IoT technology can predict people’s needs and respond accordingly. For example, a manufacturing robot can adjust its speed to match workers. Alternatively, warehouse machines can switch their order picking routes to avoid delays.

Is the Internet of Things the future of manufacturing?

In the past few years, industrial robotics has received increasing attention. It is one of the fastest growing sectors and has significantly reshaped the manufacturing industry. Many manufacturing professionals have realized how lucrative robotic IoT in manufacturing can be through strategic integration.

As the increasingly popular technology of the Internet of Things has entered people’s horizons, it may only be a matter of time before the Internet of Things becomes the new standard in manufacturing. The industry is already exploring the boundaries of robotic IoT in manufacturing, including collaborative and mobile robots.

The Internet of Robotics could have a huge, permanent impact on the industry. Because it adds value to an already valuable technology, it may increase a manufacturer's return on investment. Once they see significant returns, they'll want to take it further.

Robotic IoT in manufacturing is cost-effective, so widespread adoption should come sooner rather than later. With more than 62% of manufacturers saying robotics reduces labor costs, adding IoT technology and its data-driven insights could save them even more money.

Potential to become an industry mainstay

Robotic IoT is likely to be a disruptor. Whatever role it plays in manufacturing, it could permanently change the way industry professionals approach robotics.

The above is the detailed content of Is robotic IoT the future of manufacturing?. For more information, please follow other related articles on the PHP Chinese website!

One Prompt Can Bypass Every Major LLM's SafeguardsApr 25, 2025 am 11:16 AM

One Prompt Can Bypass Every Major LLM's SafeguardsApr 25, 2025 am 11:16 AMHiddenLayer's groundbreaking research exposes a critical vulnerability in leading Large Language Models (LLMs). Their findings reveal a universal bypass technique, dubbed "Policy Puppetry," capable of circumventing nearly all major LLMs' s

5 Mistakes Most Businesses Will Make This Year With SustainabilityApr 25, 2025 am 11:15 AM

5 Mistakes Most Businesses Will Make This Year With SustainabilityApr 25, 2025 am 11:15 AMThe push for environmental responsibility and waste reduction is fundamentally altering how businesses operate. This transformation affects product development, manufacturing processes, customer relations, partner selection, and the adoption of new

H20 Chip Ban Jolts China AI Firms, But They've Long Braced For ImpactApr 25, 2025 am 11:12 AM

H20 Chip Ban Jolts China AI Firms, But They've Long Braced For ImpactApr 25, 2025 am 11:12 AMThe recent restrictions on advanced AI hardware highlight the escalating geopolitical competition for AI dominance, exposing China's reliance on foreign semiconductor technology. In 2024, China imported a massive $385 billion worth of semiconductor

If OpenAI Buys Chrome, AI May Rule The Browser WarsApr 25, 2025 am 11:11 AM

If OpenAI Buys Chrome, AI May Rule The Browser WarsApr 25, 2025 am 11:11 AMThe potential forced divestiture of Chrome from Google has ignited intense debate within the tech industry. The prospect of OpenAI acquiring the leading browser, boasting a 65% global market share, raises significant questions about the future of th

How AI Can Solve Retail Media's Growing PainsApr 25, 2025 am 11:10 AM

How AI Can Solve Retail Media's Growing PainsApr 25, 2025 am 11:10 AMRetail media's growth is slowing, despite outpacing overall advertising growth. This maturation phase presents challenges, including ecosystem fragmentation, rising costs, measurement issues, and integration complexities. However, artificial intell

'AI Is Us, And It's More Than Us'Apr 25, 2025 am 11:09 AM

'AI Is Us, And It's More Than Us'Apr 25, 2025 am 11:09 AMAn old radio crackles with static amidst a collection of flickering and inert screens. This precarious pile of electronics, easily destabilized, forms the core of "The E-Waste Land," one of six installations in the immersive exhibition, &qu

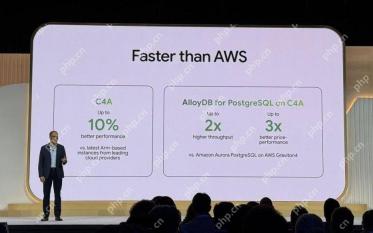

Google Cloud Gets More Serious About Infrastructure At Next 2025Apr 25, 2025 am 11:08 AM

Google Cloud Gets More Serious About Infrastructure At Next 2025Apr 25, 2025 am 11:08 AMGoogle Cloud's Next 2025: A Focus on Infrastructure, Connectivity, and AI Google Cloud's Next 2025 conference showcased numerous advancements, too many to fully detail here. For in-depth analyses of specific announcements, refer to articles by my

Talking Baby AI Meme, Arcana's $5.5 Million AI Movie Pipeline, IR's Secret Backers RevealedApr 25, 2025 am 11:07 AM

Talking Baby AI Meme, Arcana's $5.5 Million AI Movie Pipeline, IR's Secret Backers RevealedApr 25, 2025 am 11:07 AMThis week in AI and XR: A wave of AI-powered creativity is sweeping through media and entertainment, from music generation to film production. Let's dive into the headlines. AI-Generated Content's Growing Impact: Technology consultant Shelly Palme

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment

VSCode Windows 64-bit Download

A free and powerful IDE editor launched by Microsoft

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool