Technology peripherals

Technology peripherals AI

AI Domestic robots prepare to sprint to 2024: How to cope with industrial upgrading needs and become a global leader

Domestic robots prepare to sprint to 2024: How to cope with industrial upgrading needs and become a global leaderDomestic robots prepare to sprint to 2024: How to cope with industrial upgrading needs and become a global leader

The latest data shows that from January to November 2023, my country’s total industrial robot output was 387,605 sets, a year-on-year decrease of 2.8%. Compared with the growth rate in recent years, the data has declined significantly.

The overall market demand is lower than expected, which has caused some institutions to worry about the development expectations of the industrial robot industry. Over the past ten years, my country's installed capacity of industrial robots has continued to rank first in the world. In the short term, supply exceeds demand. Can future growth be sustained?

What is the "water temperature" of the market? The companies involved in it undoubtedly have the most say. Mr. Wang Hao, Vice President of Luo Shi Robot, revealed the latest developments in the current market in his speech at the 4th China Robot Industry Annual Conference in 2023: “The growth of the robot industry is still continuing, but the market is very volume, and customers are both We need quality, price, and service. Simple machine replacement or automation can no longer meet customers' diversified requirements for multiple varieties, small batches, flexible production changes, and easy operation. The industry has entered a new era of comprehensive and comprehensive requirements. stage."

So, where are the opportunities for domestic industrial robots in the new stage? What should we do if we want to surpass imported brands in market share? In the interview at the annual meeting, Luo Shi Robot analyzed the market characteristics of the new stage, and combined with its own experience, analyzed the core competitiveness of domestic brands.

▍New industry growth expectations still exist

Which industries can bring growth? Wang Hao believes that following the national strategic guidance is still the focus of growth for domestic robot companies in the next stage.

“Incremental opportunities come from the manufacturing industries that are key developments in the country,”Wang Hao explained, “Because robots are important equipment for improving efficiency and increasing income in many manufacturing industries, they need to be closely related to important industry process improvements and industries. Only by upgrading and cooperating can we enter a stage where the market space is large and application scenarios can be expanded and refined."

According to IFR data, China is the largest market in the global industrial robot market. The market size will reach US$8.7 billion in 2022, accounting for 45% of the global market. It is estimated that China's industrial robot sales will be about 300,000 units in 2022, with a compound growth rate of up to 26%, mainly used in consumer electronics, automobiles, metal products and other fields.

Currently, Luoshi's flexible collaborative robots and composite robot products have made significant progress in the 3C electronics field. They have been successfully used in key links such as mobile phone production lines and electrode processing production, achieving mass production. In addition, in the field of auto parts, Luoshi's robot products have also shown strong strength. For example, Luo Shi robots have gained mature application experience in many scenarios such as engine bolt tightening and deburring, gearbox precision assembly, door handle plastic parts grinding, piston precision deburring, and guide rail grinding. These successful cases prove the value and potential of Luoshi robots in industrial production.

At the same time, Luo Shi realized that in terms of market conditions, compared with the overall penetration rate of the 3C and automobile industries, with the rise of the new energy industry, the proportion of robots used in manufacturing production lines of lithium battery, photovoltaic and other industries is at a relatively high level. Although the level is low, it shows a rapid improvement trend year by year. To this end, Luo Shi Robot has deepened its investment in photovoltaic, lithium battery, commercial and other directions since 2020, and through in-depth process development, it has gradually reached cooperation with some leading customers.

In this process, the two product lines of industry and collaboration have not become a burden for Luoshi. Instead, they have become a rare advantage of domestic robots. Although industrial robots are technologically mature, they cannot solve the problem of generalization and are not suitable for the needs of flexible production in modern manufacturing. As one of the few domestic manufacturers that has both industrial and collaborative models, Luo Shi has products ranging from small and medium loads to large loads. It can use a diversified product portfolio to better meet customer requirements.

According to Wang Hao, Many customers have taken a fancy to Luoshi's overall product line features, such as Foxconn, BYD, China Railway 14th Bureau, Sanhua Intelligent Control and other customers. Many customers have established mutual trust through cooperation with small and medium-sized payload robots, and soon chose to use Luoshi after launching large-load robots. In addition, many customers have both industrial and collaborative robots from Luoshi on their production lines.

Wang Hao believes that photovoltaic, 3C, commercial and other customers choose Luoshi not only because of its diverse products and case base accumulated from many years of practice, but also because it has formed unique solutions for subdivided industries and can Solve key problems and bring benefits.

"Domestic medium and large robots have become the equivalent of foreign countries. The technical level of product stability and accuracy is basically the same, but the cost performance is more advantageous. This allows domestic robots to replace imports and increase market share The foundation has been laid," Wang Hao said. "Furthermore, Luo Shi Company's overall strength has been able to meet strict standards in terms of customer service and product quality assurance. This has enabled both parties to cooperate more closely during the cooperation process, and has also enabled customers to ultimately choose Luo Shi."

In 2023, due to the focus on solving process characteristics issues, Luoshi successfully deployed NB series 12kg and 25kg robots on a large scale for cell flower basket handling, cell inserting, component layout, and tooling up and down in the photovoltaic industry. Materials, component palletizing and other scenarios, large-load NB80 and NB220 are implemented in lithium battery and other fields. In addition, Luo Shi has also tried to enter new technologies in multiple industries. For example, its flexible collaborative robots are used in commercial rehabilitation physiotherapy, coffee latte art and other scenarios.

but as the industry’s awareness of robots increases With the increasing demand from major customers, it is impossible for one company to cater to all needs. In the next stage, enterprises in the robotics industry must become more refined and deeper in the segmented industries, rather than broader. Only through deep cultivation can they truly gain recognition from industry customers and gain influence in the industry.

▍Only by making good products can we have a future

Wang Hao mentioned that in recent years, the robot industry has gone through the path of automation, informatization, and overall intelligence, and has entered a period of emphasis on human-machine collaboration. Some customers require the manufacturing industry to be upgraded. They need robots to free up repetitive tasks, and they need to be able to collaborate with people without causing harm to them. They also need to maintain a good collaboration rhythm. Enterprises' requirements for robots are increasing.Luo Shi’s multiple products can meet the complex needs of customers and are inseparable from its platform product strategy. Based on the platform strategy, both product lines of Luo Shi Robot share a robot control platform. This platform is built based on the overall motion control experience and dynamics control understanding of robots that Luo Shi has accumulated over the years, making the two product lines Robots can not only meet the needs of application scenarios well, but also develop simultaneously in terms of performance,

achieving higher speed, accuracy, safety, flexibility, collaboration, and openness.

"For example, collaboration is used in areas with high requirements for safety, deployment, and intelligence, and traditional industrial robots are used for high-precision and high-speed automated substitutions. Since Luoshi's products are based on a unified control platform, it is easier to Achieve multi-product coordination, connect the needs of multiple scenarios, and finally settle on the integration of products and production lines to better meet customer needs." Wang Hao explained.

The portability of this product to many other fields comes from Luoshi’s mature robot industry chain. Since Luo Shi has been trying to develop independently for many years, it not only has the core technology in its own hands, but also has completely independent intellectual property rights. Through independent exploration in the fields of controllers, servo motors, reducers and other fields, Luoshi has now formed a component system with controllers as the core, and has rapidly expanded to servo motors and drive control integrated products. Through cooperative development with partners in areas such as force sensors and reducers, Luoshi has also established independent design standards and achieved breakthroughs in core technology understanding. The overall localization rate of parts has reached more than 98%.

According to Wang Hao,the current product and technology research and development of Luo Shi Robot will follow a rigorous process, ensuring that its products are very suitable for customer needs. At the beginning of research and development, Luoshi will first define the entire appearance structure and main parameters of the product based on customer and market demand analysis, then carry out the selection and design of main components and detailed component design, and then conduct trial production of prototypes. Finally, a complete test process and on-site testing are carried out, and mass production is entered after success, which ensures the effectiveness of research and development.

Due to the detailed demand analysis for the robot's arm span, load, speed, axis speed, etc. during the research and development stage, the entire design process will be digitally designed, will include dynamics, jitter, lightweight, and reliability The kinesiology, kinematics design and other technologies are sorted out, refined and classified, and a complete set of perfect technical systems are formed. Although the current research and development cycle of Luoshi robots is more than half a year, this multi-objective and multi-disciplinary collaborative simulation process helps Luoshi more easily ensure the reliability of parts and complete machine products, thereby creating high-quality, Products with high technological maturity can truly meet the working conditions of various enterprises and realize industry replication and "robot" empowerment from one to many.

▍Conclusion and the future

As far as the macroeconomic situation is concerned, the current country is still vigorously supporting the development of industrial robots, with frequent industrial policies, market expansion policies are very certain, and industrial robots are still on a healthy development track.

In January 2023, 17 departments including the Ministry of Industry and Information Technology released the "Implementation Plan for the "Robot" Application Action", which set the goal of doubling the density of robots in my country's manufacturing industry by 2025 compared with 2020, and designed a top-level plan for the future of China's manufacturing industry. Planning and roadmap. In 2020, the density of robots in my country's manufacturing industry will be 246 units per 10,000 people. According to this goal, it means that by 2025, it will reach about 500 units per 10,000 people. In 2022, the density of robots in China's manufacturing industry will reach 392 units per 10,000 employees. Filling the gap makes the industry's growth space worth looking forward to.

However, it has become increasingly difficult to comprehensively and widely increase the capacity of industrial robots. Because in 10 years, China's manufacturing robot density has increased by about 13 times, and its international ranking has risen from 25th in 2015 to fifth in the world. At the same time, the number of industrial robots in service in my country will exceed 1.5 million units in 2022, accounting for 10% of the world's total. The proportion of the total amount exceeds 1/3, and the newly installed capacity accounts for more than 50% of the global proportion. In the past ten years, the scale and level of my country's intelligent manufacturing applications have also entered the world's leading ranks, and the traditional demand for production capacity transformation has begun to slow down.

As the economy stabilizes, the transformation of the manufacturing industry deepens and the complexity of application scenarios increases. As an important part of intelligent manufacturing, is easy to use, intelligent, has high production efficiency and safety, and is easy to manage. , robots with significant economic benefits have been obviously more favored by enterprises.

Not only that, terminal companies also hope that robot companies will not just provide general products, but start to require robots to integrate processes into control systems and process packages, which can help companies inject new ideas into digital, networked, and intelligent development. Momentum provides new paths and profoundly changes production methods.

Of course, the high-demand trend of terminal manufacturing companies also shows that domestic robots truly have a position to compete head-on with foreign giants in the market. How to adapt to this new trend and meet the needs of industrial upgrading, and how to grow into a world-class industrial robot expert will still test the wisdom and strength of various domestic robot companies.

The above is the detailed content of Domestic robots prepare to sprint to 2024: How to cope with industrial upgrading needs and become a global leader. For more information, please follow other related articles on the PHP Chinese website!

7 Powerful AI Prompts Every Project Manager Needs To Master NowMay 08, 2025 am 11:39 AM

7 Powerful AI Prompts Every Project Manager Needs To Master NowMay 08, 2025 am 11:39 AMGenerative AI, exemplified by chatbots like ChatGPT, offers project managers powerful tools to streamline workflows and ensure projects stay on schedule and within budget. However, effective use hinges on crafting the right prompts. Precise, detail

Defining The Ill-Defined Meaning Of Elusive AGI Via The Helpful Assistance Of AI ItselfMay 08, 2025 am 11:37 AM

Defining The Ill-Defined Meaning Of Elusive AGI Via The Helpful Assistance Of AI ItselfMay 08, 2025 am 11:37 AMThe challenge of defining Artificial General Intelligence (AGI) is significant. Claims of AGI progress often lack a clear benchmark, with definitions tailored to fit pre-determined research directions. This article explores a novel approach to defin

IBM Think 2025 Showcases Watsonx.data's Role In Generative AIMay 08, 2025 am 11:32 AM

IBM Think 2025 Showcases Watsonx.data's Role In Generative AIMay 08, 2025 am 11:32 AMIBM Watsonx.data: Streamlining the Enterprise AI Data Stack IBM positions watsonx.data as a pivotal platform for enterprises aiming to accelerate the delivery of precise and scalable generative AI solutions. This is achieved by simplifying the compl

The Rise of the Humanoid Robotic Machines Is Nearing.May 08, 2025 am 11:29 AM

The Rise of the Humanoid Robotic Machines Is Nearing.May 08, 2025 am 11:29 AMThe rapid advancements in robotics, fueled by breakthroughs in AI and materials science, are poised to usher in a new era of humanoid robots. For years, industrial automation has been the primary focus, but the capabilities of robots are rapidly exp

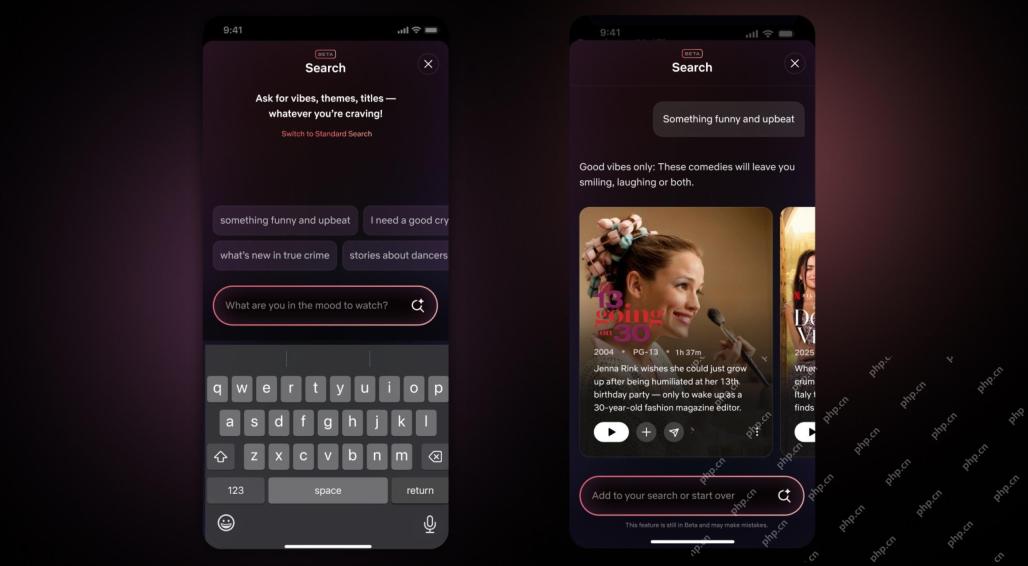

Netflix Revamps Interface — Debuting AI Search Tools And TikTok-Like DesignMay 08, 2025 am 11:25 AM

Netflix Revamps Interface — Debuting AI Search Tools And TikTok-Like DesignMay 08, 2025 am 11:25 AMThe biggest update of Netflix interface in a decade: smarter, more personalized, embracing diverse content Netflix announced its largest revamp of its user interface in a decade, not only a new look, but also adds more information about each show, and introduces smarter AI search tools that can understand vague concepts such as "ambient" and more flexible structures to better demonstrate the company's interest in emerging video games, live events, sports events and other new types of content. To keep up with the trend, the new vertical video component on mobile will make it easier for fans to scroll through trailers and clips, watch the full show or share content with others. This reminds you of the infinite scrolling and very successful short video website Ti

Long Before AGI: Three AI Milestones That Will Challenge YouMay 08, 2025 am 11:24 AM

Long Before AGI: Three AI Milestones That Will Challenge YouMay 08, 2025 am 11:24 AMThe growing discussion of general intelligence (AGI) in artificial intelligence has prompted many to think about what happens when artificial intelligence surpasses human intelligence. Whether this moment is close or far away depends on who you ask, but I don’t think it’s the most important milestone we should focus on. Which earlier AI milestones will affect everyone? What milestones have been achieved? Here are three things I think have happened. Artificial intelligence surpasses human weaknesses In the 2022 movie "Social Dilemma", Tristan Harris of the Center for Humane Technology pointed out that artificial intelligence has surpassed human weaknesses. What does this mean? This means that artificial intelligence has been able to use humans

Venkat Achanta On TransUnion's Platform Transformation And AI AmbitionMay 08, 2025 am 11:23 AM

Venkat Achanta On TransUnion's Platform Transformation And AI AmbitionMay 08, 2025 am 11:23 AMTransUnion's CTO, Ranganath Achanta, spearheaded a significant technological transformation since joining the company following its Neustar acquisition in late 2021. His leadership of over 7,000 associates across various departments has focused on u

When Trust In AI Leaps Up, Productivity FollowsMay 08, 2025 am 11:11 AM

When Trust In AI Leaps Up, Productivity FollowsMay 08, 2025 am 11:11 AMBuilding trust is paramount for successful AI adoption in business. This is especially true given the human element within business processes. Employees, like anyone else, harbor concerns about AI and its implementation. Deloitte researchers are sc

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

SublimeText3 Linux new version

SublimeText3 Linux latest version

Dreamweaver Mac version

Visual web development tools

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.