Technology peripherals

Technology peripherals AI

AI Convenience, efficiency and win-win: UAV oil and gas pipeline inspections are fully upgraded

Convenience, efficiency and win-win: UAV oil and gas pipeline inspections are fully upgradedConvenience, efficiency and win-win: UAV oil and gas pipeline inspections are fully upgraded

my country’s huge oil and gas pipeline network, including crude oil, finished product and natural gas pipelines, has put forward higher demands for pipeline safety patrol and management due to practical factors such as wide geographical area, long construction period, and frequent safety accidents. In this context, the traditional manual patrol method is obviously unable to meet the high, precise and accurate requirements. In order to improve efficiency, reduce costs, and better manage oil and gas pipelines, drone oil and gas pipeline inspections came into being.

1. Limitations of traditional patrol methods

1. Manual patrol

In traditional pipeline patrol, manual patrol has always been the most basic and common method. This method relies on patrol personnel to patrol on foot, but in areas with steep terrain, this method is greatly limited, high cost, and heavy workload. It is especially inconvenient in large-scale and long-distance pipeline monitoring.

2. Optical fiber or electronic induction inspection

The use of optical fiber or electronic induction inspection is intended to analyze and provide early warning of vibrations around the pipeline by installing optical fiber sensors. However, this method has problems such as high error rate, short range, and high cost. More importantly, this method cannot provide real-time images, nor can it provide key decision-making information to the command center, so it is limited in practicality when responding to emergencies

2. Advantages and applications of drone inspection in oil and gas pipelines

What needs to be rewritten is: 1. Convenient pipeline selection and construction

By comprehensively and quickly obtaining target terrain and landform information, drones provide a reliable basis for pipeline selection. At the same time, the drone oil and gas pipeline inspection system assists construction workers to quickly and accurately enter the construction stage by analyzing the terrain, traffic, surrounding environment and other conditions at the construction site.

Need to carry out efficient routine inspection

The drone is equipped with a visible light and infrared dual-light pod, which can efficiently complete large-scale routine inspection tasks. The pod is used to collect soil, weather, pipeline temperature and other information around the pipeline. The drone can analyze and position it, achieve timely locking and tracking of ground targets, and provide effective support for inspection work

Need flexibility when dealing with complex environments

Fuya Intelligent’s drone oil and gas pipeline inspection system shows unique advantages in adapting to changing environments. In the face of changing environments, its flexibility allows it to easily cover complex terrain and inaccessible areas. This technology not only overcomes terrain problems, but also allows inspection work to be carried out with greater flexibility and comprehensiveness. Creating new possibilities for the safety and security of the oil and gas industry

The introduction of drone oil and gas pipeline inspections not only improves patrol efficiency and reduces labor costs, but also ensures the personal safety of patrol personnel. With the continuous development of technology, Fuya Intelligent's drone oil and gas pipeline inspection system will play a more important role in the oil and gas industry, pushing oil and gas pipeline safety management into a new stage of smarter and more efficient

(Source: Financial Business Information)

Please go to the application market to download the "Jimu News" client to get more exciting information. Please do not reprint without authorization. You are welcome to provide news clues and you will be rewarded once adopted. If you have any news clues, please call the 24-hour reporting hotline: 027-86777777

The above is the detailed content of Convenience, efficiency and win-win: UAV oil and gas pipeline inspections are fully upgraded. For more information, please follow other related articles on the PHP Chinese website!

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AM

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AMLangChain is a powerful toolkit for building sophisticated AI applications. Its agent architecture is particularly noteworthy, allowing developers to create intelligent systems capable of independent reasoning, decision-making, and action. This expl

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AM

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AMRadial Basis Function Neural Networks (RBFNNs): A Comprehensive Guide Radial Basis Function Neural Networks (RBFNNs) are a powerful type of neural network architecture that leverages radial basis functions for activation. Their unique structure make

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AM

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AMBrain-computer interfaces (BCIs) directly link the brain to external devices, translating brain impulses into actions without physical movement. This technology utilizes implanted sensors to capture brain signals, converting them into digital comman

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AM

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AMThis "Leading with Data" episode features Ines Montani, co-founder and CEO of Explosion AI, and co-developer of spaCy and Prodigy. Ines offers expert insights into the evolution of these tools, Explosion's unique business model, and the tr

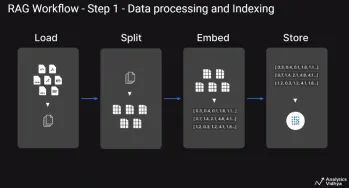

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AM

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AMThis article explores Retrieval Augmented Generation (RAG) systems and how AI agents can enhance their capabilities. Traditional RAG systems, while useful for leveraging custom enterprise data, suffer from limitations such as a lack of real-time dat

What are Integrity Constraints in SQL? - Analytics VidhyaApr 21, 2025 am 10:58 AM

What are Integrity Constraints in SQL? - Analytics VidhyaApr 21, 2025 am 10:58 AMSQL Integrity Constraints: Ensuring Database Accuracy and Consistency Imagine you're a city planner, responsible for ensuring every building adheres to regulations. In the world of databases, these regulations are known as integrity constraints. Jus

Top 30 PySpark Interview Questions and Answers (2025)Apr 21, 2025 am 10:51 AM

Top 30 PySpark Interview Questions and Answers (2025)Apr 21, 2025 am 10:51 AMPySpark, the Python API for Apache Spark, empowers Python developers to harness Spark's distributed processing power for big data tasks. It leverages Spark's core strengths, including in-memory computation and machine learning capabilities, offering

Self-Consistency in Prompt EngineeringApr 21, 2025 am 10:50 AM

Self-Consistency in Prompt EngineeringApr 21, 2025 am 10:50 AMHarnessing the Power of Self-Consistency in Prompt Engineering: A Comprehensive Guide Have you ever wondered how to effectively communicate with today's advanced AI models? As Large Language Models (LLMs) like Claude, GPT-3, and GPT-4 become increas

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

SublimeText3 English version

Recommended: Win version, supports code prompts!

SublimeText3 Chinese version

Chinese version, very easy to use

VSCode Windows 64-bit Download

A free and powerful IDE editor launched by Microsoft

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software