Technology peripherals

Technology peripherals AI

AI 'Among the top ten important robotics technology development trends, humanoid robots are indispensable'

'Among the top ten important robotics technology development trends, humanoid robots are indispensable''Among the top ten important robotics technology development trends, humanoid robots are indispensable'

Emerging robotics technology can meet people's growing needs for industrial automation, digitization, and sustainability. For example, material handling in warehouses can be automated using autonomous mobile robots (AMRs) and automated guided vehicles (AGVs).

The research institution recently conducted an in-depth study of the insights of 8,949 start-ups and large enterprises around the world on the development of robotics technology, and made predictions about the development trends of robotics technology in 2023. Industry experts point out that people need to understand and follow robotics trends that have the potential to transform businesses.

The following are the top ten robot trends and predictions for 2023 derived from the study:

1. Autonomous Mobile Robots (AMR)

In manufacturing, workers often work in hazardous environments such as toxic chemicals, confined spaces, or heavy machinery. Autonomous mobile robots use sensors, artificial intelligence and computer vision technology to observe and understand their surroundings and navigate autonomously. For example, autonomous mobile robots (AMRs) in warehouses use scanners to monitor inventory levels and automate material handling and prevent inventory depletion. To speed up work, autonomous mobile robots can also transport components and parts over long distances within factories.

2. Intelligent robot

Due to the combination of artificial intelligence and robotics, intelligent robots can use real-time information to optimize their work. Large datasets and real-time data are also used to train robots to become more accurate and effective. As a result, they are able to better perceive their surroundings, distinguish objects more quickly, and navigate independently.

3. Collaborative robots

Compared with traditional industrial robots, collaborative robots have advanced sensors and algorithms. They work with workers and must ensure that their surroundings Safety of personnel. To automate production activities such as welding parts and drilling holes, they primarily employ end-of-arm tooling (EOAT) operations. These robots help workers move hazardous items such as metal products, polymers and other materials.

4. Robots as a Service

The development and maintenance of robots is a costly and time-consuming process. Due to these constraints, many businesses, especially small ones, are unable to integrate robotics into their operations and need to use Robots-as-a-Service.

5. Robot Cybersecurity

Due to the integration of IoT and the increase in connectivity requirements, robots have become the main target of cyber attacks. Additionally, due to their widespread use in the defense, manufacturing, healthcare, and aerospace industries, robots must be protected from illegal access and intrusion. Adopting a robotic cybersecurity solution protects endpoints and connectivity stacks to prevent data breaches and asset outages.

6. Drones

Thanks to the development of edge computing, high-performance computing and network technology, startups are now able to build drones with greater range and capabilities. machine. They use drones to deliver goods, collect aerial data, inspect infrastructure, and do a wide variety of operations. Drones used in agriculture can spray pesticides and sow seeds at specific locations while monitoring crop growth and tracking the movement of livestock. The adaptability of drones has accelerated integration in last-mile transportation of things like food and medical supplies.

7. Internet of Things

If robotics focuses on manufacturing, interaction and autonomous behavior, the Internet of Things provides sensing, monitoring and tracking functions. The robot's performance is driven by an edge computing platform, which enables feedback-driven workflows by collecting and sending data. Thanks to recent advances in edge IoT, robot manufacturers are now able to move computing closer to the data source. This allows the robot to use nearly real-time data and maximize work efficiency.

8. Humanoid robots

In the post-epidemic era, humanoid robots are increasingly used for non-contact cleaning and patient care. In addition, they are used in power plant inspections, maintenance and post-disaster recovery operations to rescue workers from hazardous environments. In addition to greeting guests at the front desk, humanoid robots will also look after the sick and elderly. They, like other robots, automate work to reduce expenses and boost production.

9. Automated Guided Vehicles

In warehouses, distribution centers and production facilities, materials are often transported by automated guided vehicles. Their movement is controlled by software and a sensor-based navigation system that follows a predetermined path.

10. Assistive Robots

More and more people will benefit from the independence and higher quality of life provided by assistive robots. To sense, process and communicate with humans, assistive robots use sensors and smart algorithms to allow people to live independently and safely in their own homes.

The above is the detailed content of 'Among the top ten important robotics technology development trends, humanoid robots are indispensable'. For more information, please follow other related articles on the PHP Chinese website!

One Prompt Can Bypass Every Major LLM's SafeguardsApr 25, 2025 am 11:16 AM

One Prompt Can Bypass Every Major LLM's SafeguardsApr 25, 2025 am 11:16 AMHiddenLayer's groundbreaking research exposes a critical vulnerability in leading Large Language Models (LLMs). Their findings reveal a universal bypass technique, dubbed "Policy Puppetry," capable of circumventing nearly all major LLMs' s

5 Mistakes Most Businesses Will Make This Year With SustainabilityApr 25, 2025 am 11:15 AM

5 Mistakes Most Businesses Will Make This Year With SustainabilityApr 25, 2025 am 11:15 AMThe push for environmental responsibility and waste reduction is fundamentally altering how businesses operate. This transformation affects product development, manufacturing processes, customer relations, partner selection, and the adoption of new

H20 Chip Ban Jolts China AI Firms, But They've Long Braced For ImpactApr 25, 2025 am 11:12 AM

H20 Chip Ban Jolts China AI Firms, But They've Long Braced For ImpactApr 25, 2025 am 11:12 AMThe recent restrictions on advanced AI hardware highlight the escalating geopolitical competition for AI dominance, exposing China's reliance on foreign semiconductor technology. In 2024, China imported a massive $385 billion worth of semiconductor

If OpenAI Buys Chrome, AI May Rule The Browser WarsApr 25, 2025 am 11:11 AM

If OpenAI Buys Chrome, AI May Rule The Browser WarsApr 25, 2025 am 11:11 AMThe potential forced divestiture of Chrome from Google has ignited intense debate within the tech industry. The prospect of OpenAI acquiring the leading browser, boasting a 65% global market share, raises significant questions about the future of th

How AI Can Solve Retail Media's Growing PainsApr 25, 2025 am 11:10 AM

How AI Can Solve Retail Media's Growing PainsApr 25, 2025 am 11:10 AMRetail media's growth is slowing, despite outpacing overall advertising growth. This maturation phase presents challenges, including ecosystem fragmentation, rising costs, measurement issues, and integration complexities. However, artificial intell

'AI Is Us, And It's More Than Us'Apr 25, 2025 am 11:09 AM

'AI Is Us, And It's More Than Us'Apr 25, 2025 am 11:09 AMAn old radio crackles with static amidst a collection of flickering and inert screens. This precarious pile of electronics, easily destabilized, forms the core of "The E-Waste Land," one of six installations in the immersive exhibition, &qu

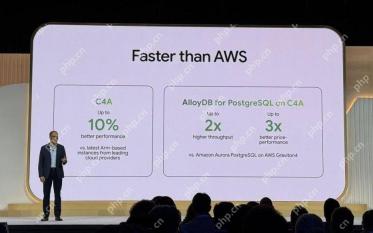

Google Cloud Gets More Serious About Infrastructure At Next 2025Apr 25, 2025 am 11:08 AM

Google Cloud Gets More Serious About Infrastructure At Next 2025Apr 25, 2025 am 11:08 AMGoogle Cloud's Next 2025: A Focus on Infrastructure, Connectivity, and AI Google Cloud's Next 2025 conference showcased numerous advancements, too many to fully detail here. For in-depth analyses of specific announcements, refer to articles by my

Talking Baby AI Meme, Arcana's $5.5 Million AI Movie Pipeline, IR's Secret Backers RevealedApr 25, 2025 am 11:07 AM

Talking Baby AI Meme, Arcana's $5.5 Million AI Movie Pipeline, IR's Secret Backers RevealedApr 25, 2025 am 11:07 AMThis week in AI and XR: A wave of AI-powered creativity is sweeping through media and entertainment, from music generation to film production. Let's dive into the headlines. AI-Generated Content's Growing Impact: Technology consultant Shelly Palme

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

WebStorm Mac version

Useful JavaScript development tools

Dreamweaver CS6

Visual web development tools

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.