Technology peripherals

Technology peripherals AI

AI Accelerate the construction of the Internet of Things in oil and gas stations in Jilin Oilfield to improve efficiency

Accelerate the construction of the Internet of Things in oil and gas stations in Jilin Oilfield to improve efficiencyAccelerate the construction of the Internet of Things in oil and gas stations in Jilin Oilfield to improve efficiency

Recently, in the courtyard of the Honggang Oil Production Plant Joint Station, digital intelligence technicians are constructing the station security project. They are installing cameras and integrating video surveillance with daily supervision through the IoT cloud platform. In this way, they can detect problems in time and deal with them, achieving round-the-clock dynamic control and ensuring safety

So far, the Jilin Oilfield Oil and Gas Station Internet of Things construction project has been progressing efficiently, and it is expected that by the end of the year, 100% of this year’s goal will be achieved

Jilin Oilfield Oil and Gas Station Internet of Things Construction Project is a basic project to achieve the transformation and development of "two informatizations". The main goal of this project is to gradually optimize the IoT functions of the entire oilfield to achieve integrated and efficient linkage of wells, rooms, and stations, prepare for unattended stations, and accelerate the construction process of intelligent stations throughout the oilfield. This project was launched in February this year and is expected to last three years and involve five oil production plants including Fuyu, Honggang, Xinli, Changchun and Qian'an. Strive to complete the comprehensive construction and put it into use by May 2024

In order to achieve high-quality work and outstanding results, Jilin Oilfield adopts the construction model of demonstration first and gradual advancement, first focusing on building the model station of the oil and water treatment center of Fuyu Oil Production Plant. During the application process, we constantly summarize experience, improve and improve, and promote the construction of the Internet of Things in stations and sites in stages. We successfully built a demonstration station for the oil and water treatment center of Fuyu Oil Production Plant and developed a low-cost intelligent solution for Jilin Oilfield with the characteristics of comprehensive system digitization, reliable automation and practical intelligence. At the same time, we completed the construction of the Internet of Things at the Honggang oil production plant station and basically brought the data in the station online. We are also gradually improving the functions of the station control system and transforming and supplementing some hardware facilities. At the same time, we will continue to promote the construction of the Internet of Things in Fuyu, Qian'an, Changchun and Xinzhan stations

In the past seven months, all employees have worked overtime to ensure the construction deadline and strive for progress. This effort has achieved the "Three Ones" phased results:

A standard system has been built. We have fully implemented the automation transformation of gathering and transportation, sewage, heating, water injection and loading and unloading positions, and formed a complete set of in-station data collection, automatic control and logic control systems. We have created the "four modernizations" intelligent station management model, making unattended and "black screen" factories a reality. Now, operators can fully understand the production parameters of oil and gas production sites with just a click of the mouse, making production operations simpler and faster. This not only greatly reduces the labor intensity of employees, but also greatly improves work efficiency

Through comprehensive collection and intelligent integration of production data, we have successfully created a standard platform. This platform integrates the data resources of all systems, establishes a digital production command center, and achieves centralized display and integrated management and control. We accelerated the construction of the master data of the digital management platform and integrated the well network, power grid and pipeline network into one, achieving visual and intelligent display. In this way, we form a "smart brain" for site management, so that the information in the site can be traced, passed on and shared

By relying on the production command center platform, we have successfully established a new centralized monitoring model for joint station hosting and transfer stations. This model can reduce personnel without reducing management capabilities, and reduce costs without reducing safety levels, providing effective support for the reform of operating areas under the "oil company" model

The above is the detailed content of Accelerate the construction of the Internet of Things in oil and gas stations in Jilin Oilfield to improve efficiency. For more information, please follow other related articles on the PHP Chinese website!

What is Few-Shot Prompting? - Analytics VidhyaApr 22, 2025 am 09:13 AM

What is Few-Shot Prompting? - Analytics VidhyaApr 22, 2025 am 09:13 AMFew-Shot Prompting: A Powerful Technique in Machine Learning In the realm of machine learning, achieving accurate responses with minimal data is paramount. Few-shot prompting offers a highly effective solution, enabling AI models to perform specific

What is Temperature in prompt engineering? - Analytics VidhyaApr 22, 2025 am 09:11 AM

What is Temperature in prompt engineering? - Analytics VidhyaApr 22, 2025 am 09:11 AMPrompt Engineering: Mastering the "Temperature" Parameter for AI Text Generation Prompt engineering is crucial when working with large language models (LLMs) like GPT-4. A key parameter in prompt engineering is "temperature," whi

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AM

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AMThis article explores the growing concern of "AI agency decay"—the gradual decline in our ability to think and decide independently. This is especially crucial for business leaders navigating the increasingly automated world while retainin

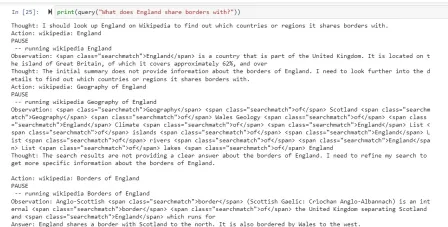

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AM

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AMEver wondered how AI agents like Siri and Alexa work? These intelligent systems are becoming more important in our daily lives. This article introduces the ReAct pattern, a method that enhances AI agents by combining reasoning an

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM"I think AI tools are changing the learning opportunities for college students. We believe in developing students in core courses, but more and more people also want to get a perspective of computational and statistical thinking," said University of Chicago President Paul Alivisatos in an interview with Deloitte Nitin Mittal at the Davos Forum in January. He believes that people will have to become creators and co-creators of AI, which means that learning and other aspects need to adapt to some major changes. Digital intelligence and critical thinking Professor Alexa Joubin of George Washington University described artificial intelligence as a “heuristic tool” in the humanities and explores how it changes

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AM

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AMLangChain is a powerful toolkit for building sophisticated AI applications. Its agent architecture is particularly noteworthy, allowing developers to create intelligent systems capable of independent reasoning, decision-making, and action. This expl

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AM

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AMRadial Basis Function Neural Networks (RBFNNs): A Comprehensive Guide Radial Basis Function Neural Networks (RBFNNs) are a powerful type of neural network architecture that leverages radial basis functions for activation. Their unique structure make

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AM

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AMBrain-computer interfaces (BCIs) directly link the brain to external devices, translating brain impulses into actions without physical movement. This technology utilizes implanted sensors to capture brain signals, converting them into digital comman

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

Dreamweaver Mac version

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool

WebStorm Mac version

Useful JavaScript development tools