Home >Technology peripherals >AI >Swiss company Flybotix has developed a dual-rotor drone that can effectively replace manual operations in complex closed industrial environments.

Swiss company Flybotix has developed a dual-rotor drone that can effectively replace manual operations in complex closed industrial environments.

- WBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBforward

- 2023-11-27 17:43:301841browse

Flybotix is a Swiss robotics technology company founded in 2019. The new ASIO drone developed by the company uses patented propulsion and steering technology, flight control algorithms and aerospace-grade materials, successfully achieving twice the flight time and being more impact-resistant. ASIO drones can effectively replace humans by entering complex closed industrial environments for inspection to ensure the safety of personnel

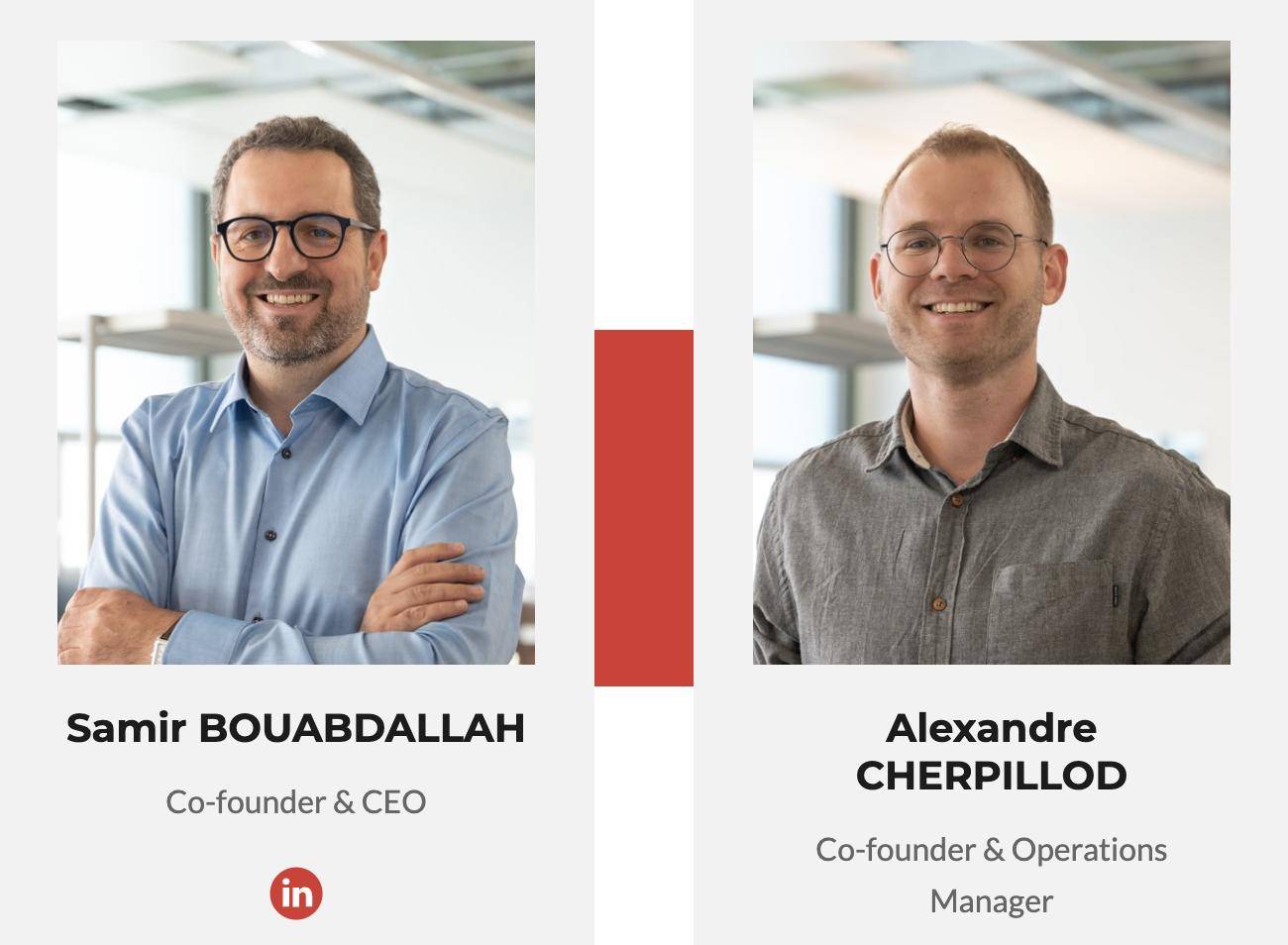

Flybotix is a spin-out company from the Ecole Polytechnique Fédérale de Lausanne (EPFL), co-founded by Alexandre Cherpillod and Samir Bouabdallah. Among them, the company’s CEO and co-founder Samir Bouabdallah has 15 years of experience in developing drone technology, and Alexandre Cherpillod has also conducted research in the field of robotics for many years.

In recent years, drones have been increasingly used for indoor inspections, covering industries such as hydroelectric power plants, oil and gas, maritime and chemical industries. They can replace manual entry into dangerous, closed or difficult-to-reach industrial environments such as sewers, pressure pipes, industrial storage tanks or chimneys, and have high detection efficiency. It is understood that the total commercial drone market reached US$15 billion last year, of which drones used for oil and gas industry inspections are one of the fastest growing areas, with a growth rate of 126% and a market value of approximately US$1.3 billion. Dollar

Traditional quad-rotor drones have excellent flight stability and can hover in place, making it convenient for fixed-point and close inspections. But when space is limited and the size of the drone shrinks, the aerodynamic efficiency of its rotor system will gradually decrease. Due to heavy batteries and inefficient propellers, quadcopter drones have a short flight life and require frequent mission interruptions to replace batteries or recharge, making a single flight time and range very limited. Moreover, the external materials of some drones are fragile and are easily damaged by collisions during missions in enclosed spaces.

The new drone product ASIO developed by Flybotix uses a patented electromagnetic levitation propulsion and steering system, combined with aerospace-grade lightweight materials and advanced flight control algorithms, to successfully double the flight time

ASIO adopts a coaxial propulsion system design, which is different from quad-rotor aircraft. ASIO's fuselage shaft is equipped with a vertically distributed propeller at each end. This design combines the mechanical simplicity of a drone with the aerodynamic efficiency of a helicopter. When ASIO takes off, the airflow between the two rotors superimposes on each other, using less energy to generate lift. At the same time, ASIO uses electromagnetic systems and advanced control algorithms to replace the classic mechanical stabilization system. By carrying various sensors, it collects information such as fuselage attitude, motion data and surrounding environment to simulate and balance the rotational force generated by the two rotors of the drone, giving it the same aerodynamic performance as a helicopter. ASIO's body material uses a cage made of aviation-grade materials, making it lightweight without sacrificing crash resistance. ASIO combines the simplicity of a multi-rotor with the aerodynamic efficiency of a helicopter and lightweight materials to achieve at least twice the flight time of similar drones on the market, with a single flight lasting up to 24 minutes

ASIO has the characteristics of collision resistance, small size and low noise. In order to cope with complex environments, ASIO's main body is equipped with a "protective cover" made of thermoplastic carbon fiber composite material to prevent the fuselage and propellers from colliding with obstacles. The overall width of the drone remains within 39 centimeters, and due to its light material and steering technology that utilizes the principle of magnetic levitation, the drone is more flexible and easier to control. The noise is also significantly reduced, and it can smoothly enter narrower and more complex spaces for safety inspections.

In 2021, Flybotix will begin delivering drone products to the market, and at the same time provide customers with a complete indoor inspection solution ASIO PRO, including drones, flight applications, and data collection and analysis system ASIO Explore. Currently, Flybotix has signed distribution agreements with Canada, France, Italy, Greece and Cyprus, and its products will be used for indoor inspection of confined spaces, such as oil tanks, underground mines, or Underground drainage pipes.

В конце 2022 года Flybotix привлекла 5,5 миллионов швейцарских франков в рамках финансирования серии А. Flybotix планирует дальнейшее развитие возможностей автономной навигации ASIO и разработку облачной версии для системы сбора и анализа данных дронов ASIO Explore, формируя модель программного обеспечения как услуги (SaaS) для обеспечения надежного и практичного оборудования и реальных возможностей. для обнаружения и обслуживания промышленных объектов.Программное обеспечение Plug and Play.

Источник: Технология Имин

The above is the detailed content of Swiss company Flybotix has developed a dual-rotor drone that can effectively replace manual operations in complex closed industrial environments.. For more information, please follow other related articles on the PHP Chinese website!

Related articles

See more- Technology trends to watch in 2023

- How Artificial Intelligence is Bringing New Everyday Work to Data Center Teams

- Can artificial intelligence or automation solve the problem of low energy efficiency in buildings?

- OpenAI co-founder interviewed by Huang Renxun: GPT-4's reasoning capabilities have not yet reached expectations

- Microsoft's Bing surpasses Google in search traffic thanks to OpenAI technology