Home >Technology peripherals >AI >Peitian's new generation robot control engine ReaLink-Motion opens a new era of AI for robot control systems

Peitian's new generation robot control engine ReaLink-Motion opens a new era of AI for robot control systems

- WBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBforward

- 2023-09-19 19:17:091449browse

With the development of physics engines, simulation environments and other related technologies, robot behavior and learning and training costs are rapidly decreasing, and new robot control technologies are expected to achieve breakthroughs. Compared with the current traditional deterministic algorithm control, the robot's movement will be transformed into a probabilistic control and data-driven artificial intelligence (AI) control method. Peitian Robot's new generation robot control engine ReaLink-Motion hopes to use AI technology to achieve the ultimate in hand-eye coordination, transforming step-by-step instructions on how to do a robot into simply telling the robot what to do. It is hoped that in a rapidly changing environment, robots can adapt and maintain high-speed, precise and smooth work like humans

The new generation of information and communication technology represented by cloud computing, big data, artificial intelligence, 5G, etc. is promoting the global industrial manufacturing industry to become digital, networked, and intelligent. The "14th Five-Year Plan" Intelligent Manufacturing Development Plan issued by eight departments including the Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Education, and the Ministry of Science and Technology clarified that during the "14th Five-Year Plan" and for a long time to come, intelligent manufacturing must be promoted based on the essence of manufacturing. Closely following the characteristics of intelligence, artificial intelligence is listed as a key core research technology. As early as 2017, the State Council has issued the "New Generation Artificial Intelligence Development Plan", which lists intelligent manufacturing as the primary task of implementing the new generation of intelligence in the real economy. Artificial intelligence will become the main driving force for my country's industrial upgrading and economic transformation. Currently, AI technology has made huge breakthroughs in cognitive fields such as face recognition and human-computer interaction. However, in the field of robots, due to the lack of behavior and task data, the establishment of large data-driven models is hindered, making it difficult for robots to achieve intelligent breakthroughs. Peitian Robot is based on the independently developed new generation robot control engine ReaLink-Motion, which is the engineering implementation of AI technology. This controller is based on Peitian Robot ReaLink large model system, which combines deep neural networks and reinforcement learning technology. Behavior simulation and data engine driven technology learn control strategies with highly dynamic characteristics. At the same time, this technology lowers the programming threshold for robotic arms, transforming teaching the robot How to do into simply telling it What to do, achieving low-code/zero-code deployment, allowing industrial robots to perform quickly in line changes and complex action scenarios. Large-scale applications are possible.

Currently, the ReaLink-Motion motion engine has implemented table tennis ball-bumping training in highly dynamic scenarios. Bumping has the characteristics of fast ball speed and variable racket angles, which are difficult to capture dynamically with ordinary cameras. However, traditional control methods are generally difficult to model and have a single bumping mode and poor robustness. Peitian Robot is based on the latest ReaLink-Motion motion engine. The control system enables the robotic arm to achieve millisecond-level precise control within milliseconds, thereby achieving stable and high-precision ball rolling.

The large payload robot in the sky has been equipped

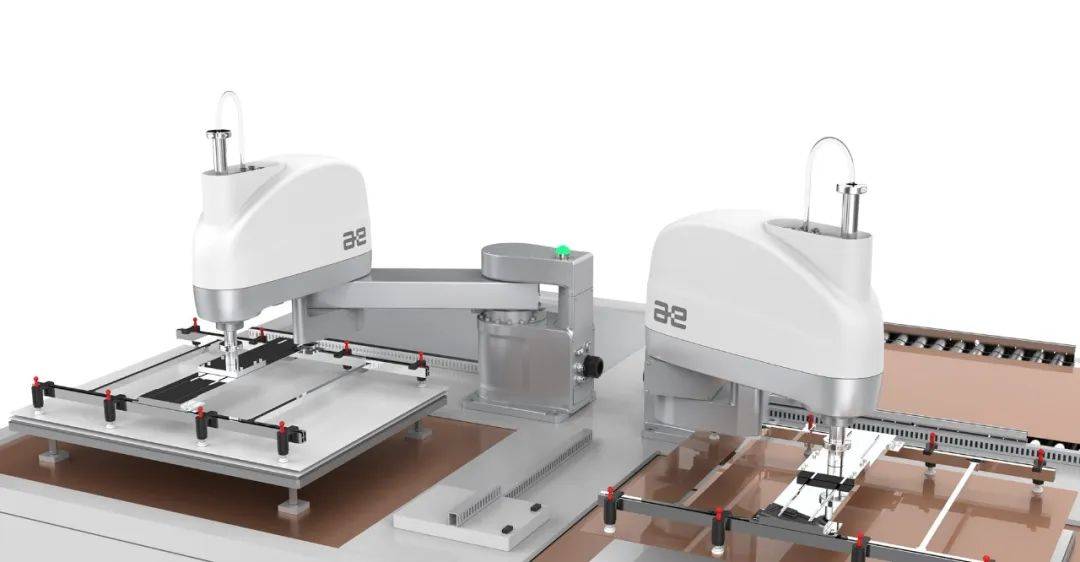

With the rise of the lithium battery and new energy automobile industries, the demand and scenarios for large-load robots have been broadened at the same time. Major robot manufacturers have laid out large-load models. Peitian Robot responded to the market by launching large-load SCARA robots. Peitian currently has a full range of SCARA robot products with payloads ranging from 3 kg to 20 kg. Peitian Robot has optimized the domestic brand SCARA robot from 10 kg to 12 kg to meet the actual needs of more customers and greatly enhance its advantages in large loads.

In addition to its advantages in load, other performance is equally impressive. Peitian's large-load SCARA robot has the characteristics of large inertia and high rigidity. It is suitable for carrying large-sized and large-eccentric workpieces for high-speed transportation, which broadens the application scenarios. Compared with the traditional and economical external bellows wiring method, the world's leading manufacturers are gradually moving towards the internal hollow wiring method. The 20kg SCARA launched by Peitian Robot is the first domestic 20kg SCARA robot without external bellows. It uses internal The hollow wiring design minimizes interference with the external space, effectively suppresses vibration and residual vibration during high-speed transportation, and makes the machine body run more smoothly. At the same time, the sky-matching robot has also provided an optimization plan in terms of protection level. A drip-proof and dust-proof version can be selected for harsh conditions such as moisture, dust, and oil mist. There are also more options for robot installation. You can choose formal installation, reverse installation, or wall installation according to the needs of actual application scenarios to achieve reasonable and effective use of space.

The 23rd China International Industrial Expo will be held grandly at the Shanghai National Convention and Exhibition Center from September 19 to 23, 2023. The theme of this expo is "Inheriting Craftsmanship, Creating the Future". Peitian Robot will showcase a variety of the latest solutions in the industry and participate in this event with a number of partners. We eagerly look forward to your visit!

Booth number: 7.1H B113

Address: National Convention and Exhibition Center (Shanghai)

The above is the detailed content of Peitian's new generation robot control engine ReaLink-Motion opens a new era of AI for robot control systems. For more information, please follow other related articles on the PHP Chinese website!

Related articles

See more- Technology trends to watch in 2023

- How Artificial Intelligence is Bringing New Everyday Work to Data Center Teams

- Can artificial intelligence or automation solve the problem of low energy efficiency in buildings?

- OpenAI co-founder interviewed by Huang Renxun: GPT-4's reasoning capabilities have not yet reached expectations

- Microsoft's Bing surpasses Google in search traffic thanks to OpenAI technology