Home >Technology peripherals >AI >This wheel-legged robot from Harbin Institute of Technology has released version 3.0! Demystifying its design, controls and performance testing

This wheel-legged robot from Harbin Institute of Technology has released version 3.0! Demystifying its design, controls and performance testing

- PHPzforward

- 2023-09-13 15:41:051126browse

DARPA (U.S. Defense Advanced Research Projects Agency) Robot Challenge (DRC) Held every two years and sponsored by the U.S. Department of Defense, the competition hopes to select robots that can perform tasks that humans cannot do at the Fukushima nuclear power plant. A robot that is responsible for on-site first aid when approaching hazards.

In the 2015 DRC DARPA Robot Challenge, the robot DRC-HUBO from South Korea relied on its "unique skills" to defeat 22 other top robots from 5 countries and won the championship. Among them There were many star robots such as Atlas and Japan's HRP developed by Boston Dynamics at that time.

DRC-HUBO is a robot that can both stand and kneel

In the field of robotics, walking balance has always been an insurmountable gap. This is also the key to HUBO's final victory-The wheels installed on its knees and ankles allow the robot to switch from walking mode to wheeled movement. The "KAIST" team that developed it also won a $2 million grand prize at the time.

Exploration and rescue in dangerous environments are important applications of robot leg motion. Robots used for disaster rescue or field exploration are often required to have the ability to move quickly on flat roads and adapt to complex terrain. Based on this problem, a team from the State Key Laboratory of Robotics and Systems, School of Mechanical and Electrical Engineering, Harbin Institute of Technology, developed a highly maneuverable and highly adaptable hydraulically powered autonomous wheel-legged robot system - the WLR-3P robot. This robot can move quickly and efficiently on flat roads, and has excellent adaptability in rugged terrain environments.

This research was published under the title of the paper (Design and Control for WLR-3P: A Hydraulic Wheel-Legged Robot) in Cyborg and Bionic Systems, a new issue of the China Science and Technology Journal Excellence Action Plan High Starting Point.

▍Unveil the mystery of WLR-3P robot

Let’s first take a look at what WLR-3P looks like:

new type of hoseless hydraulic wheel-legged robot, WLR-3P is capable of jumping and moving quickly with autonomous power.

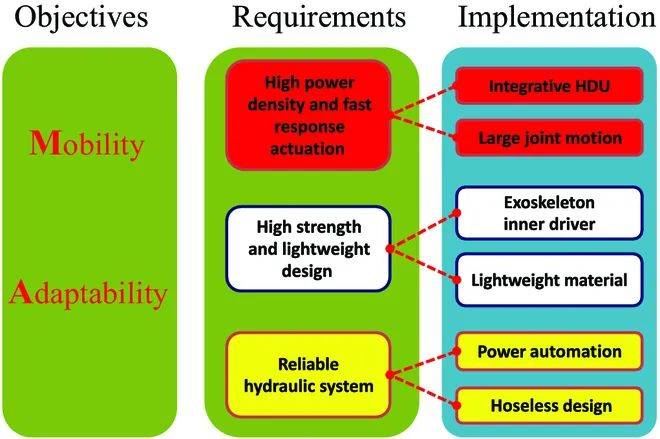

So how do researchers improve themaneuverability and environmental adaptability of robots? Mainly relies on these three points: (a) high power density and fast response drive, (b) light weight, large inertia and high strength, (c) reliable hydraulic system.

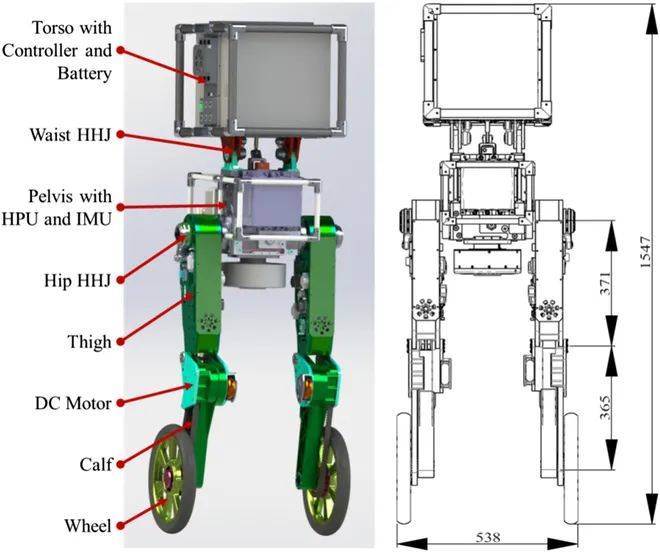

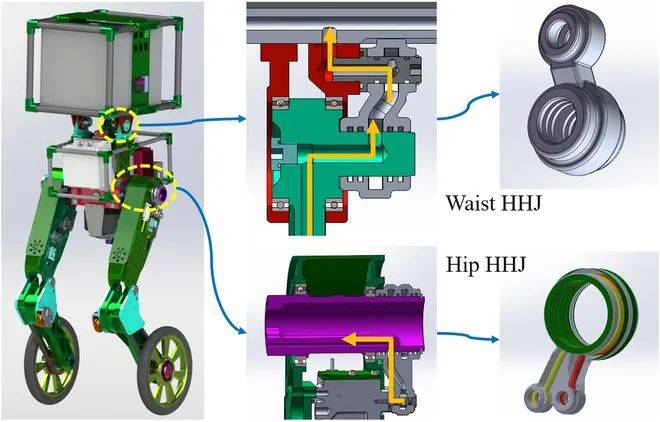

As shown above, the WLR-3P has 7 degrees of freedom (DOF): 3 DOF for each leg and 1 DOF at the waist. The three degrees of freedom of the leg are respectively on the hip joint, knee joint and driving wheel. The hip joint and knee joint are driven by HDU, and the driving wheel is driven by DC motor.

HDU includes customized high frequency response (20Hz) servo cylinder, high performance servo valve, displacement sensor and force sensor. The WLR-3P weighs 80 kg and comes with an onboard HPU and battery. The maximum height is 1.55 meters and the distance between the two wheels is approximately 0.54 meters. In addition, for safety reasons, the robot also "carries" a 1.8 kg carbon fiber hybrid aluminum alloy frame

As for why choose hydraulic? To put it simply and crudely,

robots using integrated hydraulic drive devices have high power density and fast drive response.

▍Advanced design and control strategy of WLR-3P

Researchers took into account the following factors: (a) high power-to-weight ratio, (b) excellent impact resistance, (c) high-frequency response for force/position control, and (d) biological properties comparable to humans .

The maximum power density of the knee joint hydraulic drive unit (HDU) in WLR-3P can reach about 7kW/kg, which is much higher than traditional motors. Rewritten content: The maximum power density of the knee hydraulic drive unit (HDU) in the WLR-3P is approximately 7 kW/kg, far exceeding that of conventional motors

WLR-3P’s hips and waist HHJ

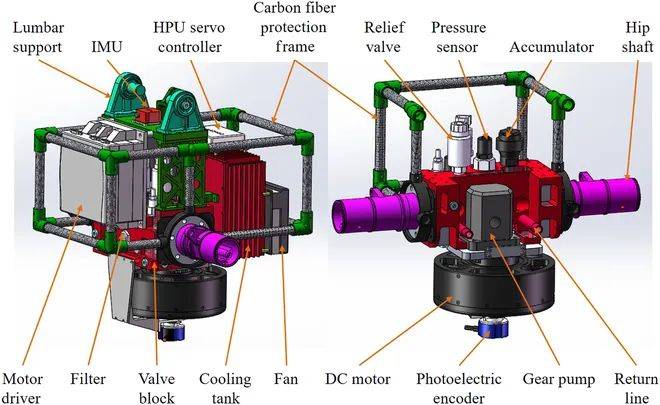

The miniaturization and integration of hydraulic power units (HPU) are the main difficulties in the field of hydraulic robot research, mainly due to the miniaturization of pumps and engines and system heating. Because WLR-3P does not have a large HPU installation space. R&D personnel have proposed an innovative design idea to achieve miniaturization and integration of HPU.

First, the gear pump is driven by a custom-made external rotor motor through a micro-coupling. High-pressure oil from the pump passes through a micro accumulator and filter to provide the hydraulic power required by the system. Secondly, in order to solve the heating problem of the system, a multi-functional fuel tank integrating heat dissipation, filtration and voltage stabilization was designed. Finally HPU can output hydraulic power with a maximum pressure of 21 MPa and a flow rate of 20 l/min.

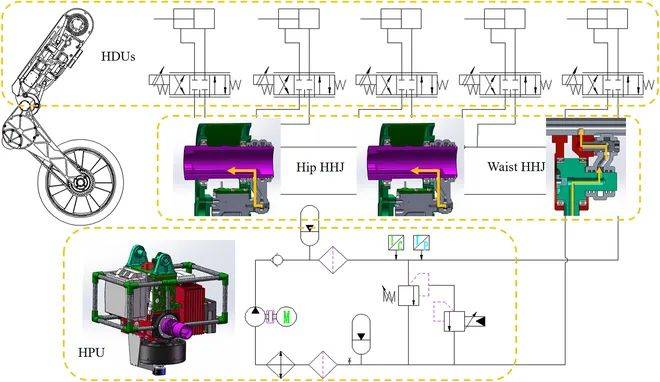

The hydraulic schematic diagram of the hydraulic system needs to be complete

The following figure shows the structure and composition of the HPU. The miniaturization and integration of HPU free the robot from the limitations of rubber hoses, making the robot's movement more "silky".

The structure and composition of HPU is also the pelvis of WLR-3P

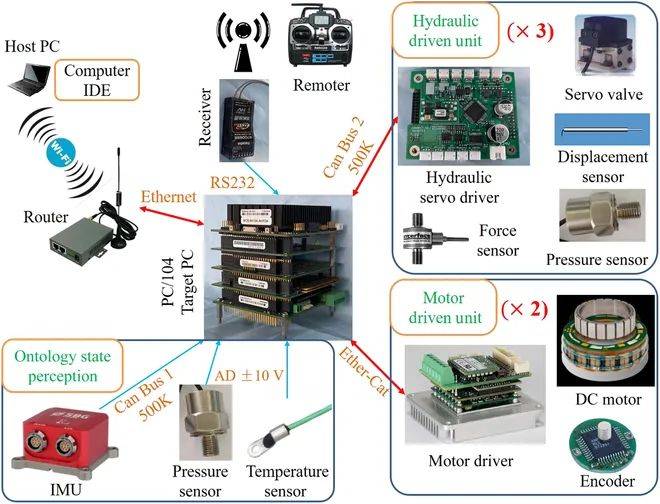

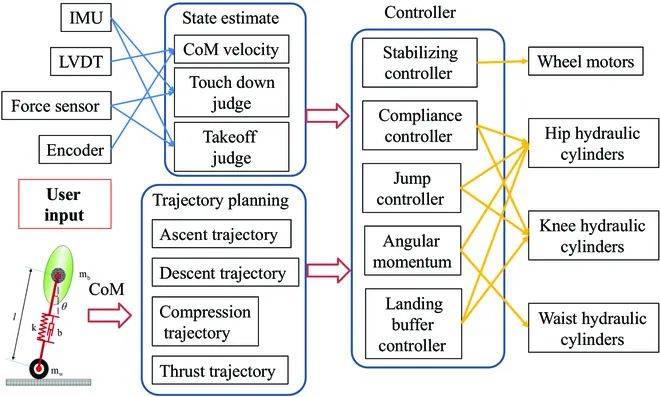

In addition, the R&D team also proposed a control system including a hierarchical distributed electrical system and control strategy:

The content that needs to be rewritten is: WLR-3P’s electronic system

WLR-3P control framework

The content that needs to be rewritten is: ▍Balance and explosive power testing of WLR-3P

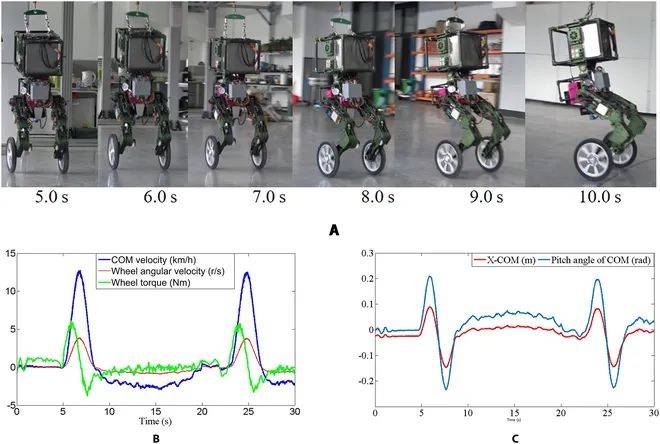

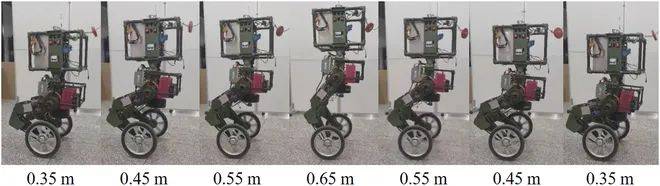

The researchers conducted tests around balanced performance and explosive power. Quick movement and squatting are the most basic actions to verify the balance performance of the wheel-legged robot. When moving quickly, the robot's center of mass (COM) changes rapidly in the horizontal direction, while when squatting, the COM changes rapidly in the vertical direction.

Quick Mobile Test

COM Squat snapshots in the height range of 0.35 and 0.65 m

The test shows that the horizontal and vertical balance capabilities of WLR-3P are OK, which also verifies the reliability of the robot hardware system.

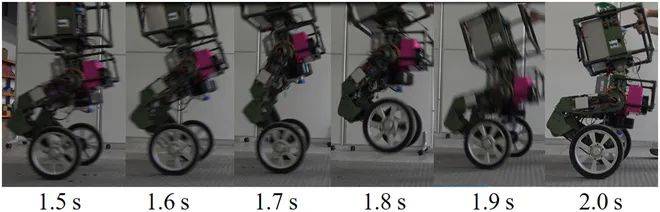

WLR-3P can complete takeoff, flight and landing processes in 0.5 seconds

The experimental results show that the robot WLR-3P can reach a speed of 13.6 km/h and a jumping height of 0.2 m. The hydraulic drive and the robot's structural settings are fully certified.

The researchers summarized their experimental experience and found that the lighter the weight of the robot and the stronger the explosive power of the drive system, the higher the robot can jump. In particular, the smaller the proportion of leg weight to body weight, the higher the instantaneous output force and speed of the knee joint, which will have a more significant impact on the robot's jumping performance.

The content that needs to be rewritten is: ▍WLR-3P’s two “brothers”

The team stated that although there is still a certain gap between actual performance and theoretical design performance, this also points out the direction for future work

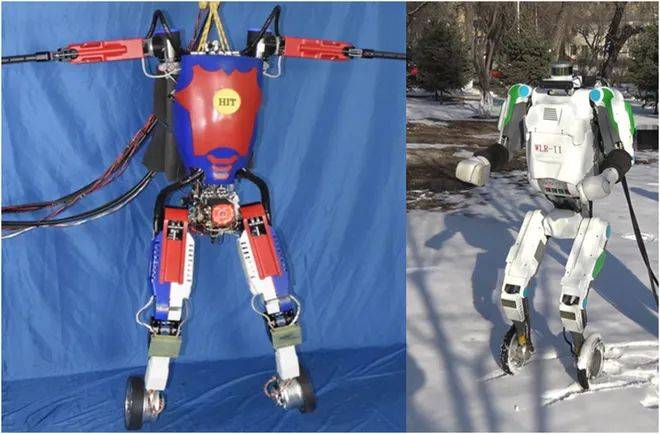

In 2017, the team has developed the first hydraulic wheel-legged robot WLR-I and successfully verified its integrated design and compound movement capabilities. Then in 2018, the second-generation wheel-legged robot WLR-II came out, achieving a hoseless design for the first time and showing unexpected terrain adaptability

Two brothers are conducting joint movement and snow mobility tests

As shown in the picture above, the first two generations of robots have actually verified 's adaptability to complex terrain and maneuverability on the ground, but they are all powered by external pumping stations. This time WLR-3P has made substantial improvements based on the design of the first two generations of wheel-legged robots. Not only improves athletic ability, but also achieves power autonomy.

Next, the team also needs to consider how to match the output power of the HPU and the power required by the HDU. Regarding the requirements for driving power and robot movement, engineering issues such as heat dissipation and noise need to be considered. More importantly, miniaturization and customization of hydraulic components are also one of the future research directions.

I have to say that the efficiency is too high. Then stop talking nonsense and wait for the fourth brother WLR.

The above is the detailed content of This wheel-legged robot from Harbin Institute of Technology has released version 3.0! Demystifying its design, controls and performance testing. For more information, please follow other related articles on the PHP Chinese website!

Related articles

See more- Technology trends to watch in 2023

- How Artificial Intelligence is Bringing New Everyday Work to Data Center Teams

- Can artificial intelligence or automation solve the problem of low energy efficiency in buildings?

- OpenAI co-founder interviewed by Huang Renxun: GPT-4's reasoning capabilities have not yet reached expectations

- Microsoft's Bing surpasses Google in search traffic thanks to OpenAI technology