Home >Technology peripherals >AI >Enter the first 'Metaverse' future factory and embark on a journey to discover the industry in Kaos!

Enter the first 'Metaverse' future factory and embark on a journey to discover the industry in Kaos!

- WBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBforward

- 2023-07-05 11:34:071076browse

The factory area covering an area of tens of thousands of square meters has been transformed into a three-dimensional digital model. With the scrolling of the mouse, you can see the real-time dynamics of hundreds of equipment, as if you are on the scene... This is a bit Like the virtual world in the game, it represents the cutting-edge trend of future factories. It is the "Metaverse Future Factory" empowered by COSMOPlat, Haier Shanghai Washing Machine Interconnected Factory.

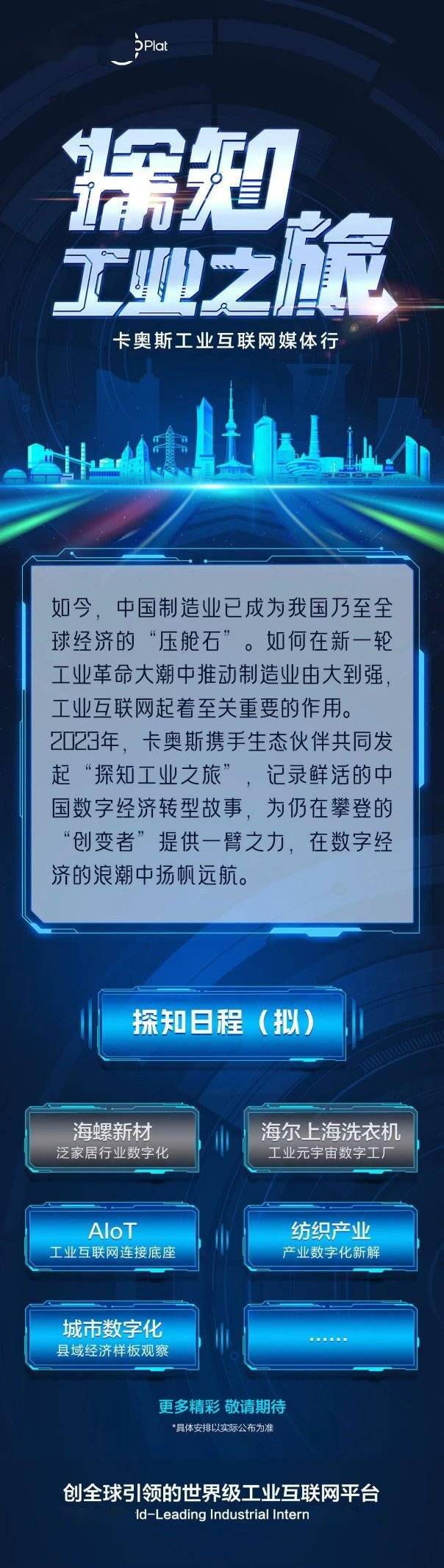

On June 27, COSMOPlat launched the second stop of its "Industrial Exploration Journey", inviting old friends and new partners from the media and industry to jointly enter the Haier Shanghai Washing Machine Interconnected Factory and witness the transformation of digital twin technology into smart products. Discuss the subversive changes brought about by manufacturing and explore the future development trends of the industrial metaverse.

Symbiosis of reality and reality, creating “two factories”

Walking into Haier’s Shanghai washing machine interconnection factory, the innovation brought about by digital twin technology is evident everywhere. When building the factory, digital twin technology established the infrastructure of the metaverse for the factory, the staff said. Through the digital model created by COSMOPlat that is completely consistent with the physical equipment and production lines in the factory, planners can continue trial and error optimization in the virtual environment to avoid ineffective projects and waste of resources, ultimately shortening the factory construction cycle by 6 months.

At the event site, visitors also tried to log in to the DT-studio of the Kaos D3OS digital twin system, built a simple production line model through code-free, drag-and-drop methods, and simulated the process arrangement to experience It ensures the efficiency and convenience of building factories in the "Industrial Metaverse".

After being put into operation, digital twin technology continues to fulfill its mission of "using virtuality to optimize reality", creating new scenarios such as production visual management, equipment predictive maintenance, and process flow self-optimization, helping factories continue to pass digitalization. "Production exercises" to find the "optimal solution" to reduce costs and increase efficiency, and achieve 100% traceability of data.

In terms of talent training, for the "new industrial workers" working in this "Yuanverse Factory", the new model of full-scenario interactive twin training runs through the open space of the entire factory, allowing them to receive on-the-job training and improve their skills. While possessing digital skills, they can also freely roam and experience in the new world of the "Industrial Metaverse", which greatly enhances their sense of belonging and interest in digital technology.

Sharing by big names, exploring the future of technology

There were many highlights during the visit, especially the world’s first Metaverse Future Factory, which opened up many new concepts for us. After the visit, the visiting media and business representatives had interactive exchanges with the relevant persons in charge of Haier and COSMOPlat, sharing and discussing the technical value of digital twins and how companies lay out the "industrial metaverse".

As a factory manager and a senior manufacturing practitioner, Chu Zhaobao, general manager of Shanghai Haier Washing Appliance Co., Ltd., said that on the one hand, digital twins bring full-process and full-scenario visualization to factory management, realizing virtual-real collaboration. Efficient resource scheduling, on the other hand, provides a starting point for enterprises to accumulate and mine industrial data, assist enterprises in scientific decision-making, and further improve production efficiency and product quality.

As for the future development of the "Industrial Metaverse". Ding Zhaozeng, Haier Kaos Industrial Intelligence Solutions Manager, said that Kaos COSMOPlat will strengthen its understanding of the "industrial metaverse", give full play to its advantages in virtual production, simulation optimization, etc., and cooperate with industry-leading enterprises and services business partners to jointly explore and practice, promote the innovative application of relevant technologies in the industrial field, and truly realize the service vision of “getting more than you see”.

"What you see on paper is only shallow, but you know that you have to do it." Returning to the "front line" of manufacturing and factories to witness and record the most authentic and vivid story of China's digital economic transformation is COSMOPlat The original intention and vision of creating "Exploring the Industrial Journey". In the future, Kaos COSMOPlat will continue to join hands with "changemakers" and "climbers" from all over China, going into the depths of the transformation of more factories, industries and regions, and witnessing the extraordinary and miracle of "intelligent manufacturing in China".

The above is the detailed content of Enter the first 'Metaverse' future factory and embark on a journey to discover the industry in Kaos!. For more information, please follow other related articles on the PHP Chinese website!

Related articles

See more- Technology trends to watch in 2023

- How Artificial Intelligence is Bringing New Everyday Work to Data Center Teams

- Can artificial intelligence or automation solve the problem of low energy efficiency in buildings?

- OpenAI co-founder interviewed by Huang Renxun: GPT-4's reasoning capabilities have not yet reached expectations

- Microsoft's Bing surpasses Google in search traffic thanks to OpenAI technology