Technology peripherals

Technology peripherals AI

AI Single-handedly raising the ceiling of the industry, he sold robots to more than 50 countries

Single-handedly raising the ceiling of the industry, he sold robots to more than 50 countriesSingle-handedly raising the ceiling of the industry, he sold robots to more than 50 countries

Dark Horse Case

Company name: Mekamande

Founder: Shao Tianlan

Dark Horse Identity: 2022 Dark Horse Competition Summer Champion

Keywords:Intelligent robot, 3D camera, vision software, robot software

Dark Horse Introduction: Mecamander is one of the world's largest AI robot innovation companies. It has advanced optical and mechanical core devices, 3D perception, vision and robot algorithms, robot software, and industry application solutions. With profound accumulation, its main products include industrial-grade high-precision 3D cameras, visual algorithm software for visual programming, and deep learning platform software. At present, 3,000 cases have been implemented, and the cumulative financing exceeds 1.5 billion yuan. In August 2022, Mecamander participated in the Dark Horse Competition organized by Entrepreneurship Dark Horse, won the first place among many high-tech enterprises, and won the 2022 Dark Horse Competition Summer Championship.

Source: i dark horse (ID:iheima)

Author: Huang Pei

In 1995, if you walked into a company or factory and found someone working on a computer, you would most likely want to take a photo - because at that time, computers were still a rare item.

But are you still surprised when you see people using computers for work today? Obviously not, because computers have entered thousands of households and have become extremely popular.

The same history may soon happen to robots.

In a bright and neat warehouse, the author saw with his own eyes a several-meter-long robotic arm "concentrating" on sorting the shelves: scanning products, rotating angles, adjusting the strength of the suction cup, and finally ingesting through the suction cup on the robot arm. The items are placed exactly where they are planned to be on the shelves - the movements are meticulous, efficient and neat.

This was originally the job of the shelf clerk, but now it can be completed by intelligent robots.

"I predict that in another five years, the robot industry will usher in an 'explosion point'. By then, in restaurants, hospitals, hotels, factories... people may see robots replacing human labor anytime and anywhere." Meka Shao Tianlan, founder of Mande Intelligent Robot, told "i Dark Horse" that the implementation and popularization of the robot industry are inseparable from the rapid development of artificial intelligence technology. “In 2016, artificial intelligence technology ushered in rapid development, and now it has even developed to the point where people don’t think it is high-tech.”

Shao Tianlan said with a hint of longing: "I believe that the next development of robots will be like artificial intelligence, rapidly penetrating into all aspects of people's work and life."

01

Step into the spotlight of the industry

Becoming attached to a robot is the result of Shao Tianlan’s active choice.

In 2012, Shao Tianlan graduated from the School of Software, Tsinghua University. After graduation, he did not follow the trend and enter the most popular Internet industry at the time as an ordinary engineer and receive an enviable high salary.

On the contrary, at the age of 23, he chose a quite bold path: out of interest in robots, he decided to go to the Technical University of Munich in Germany, a center of industrial robotics, to study for a cross-professional graduate degree in robotics.

"On the one hand, I want to challenge myself. On the other hand, I want to engage in work with a high degree of professionalism and technology-driven industry development." Shao Tianlan said that for him, researching robots to grab things or Running brings him far more happiness and sense of accomplishment than optimizing mobile phone software.

While studying in Germany, Shao Tianlan participated in the entrepreneurship of a well-known German collaborative robot company and worked for the company for three and a half years, completely participating in the entire process of collaborative robots from research and development to birth. This complete entrepreneurial experience also gave him experience and inspiration, which became one of the driving forces for him to found Mecamander after returning to China.

Entrepreneurship resources are the "geographical advantage" for entrepreneurs. Fortunately, in addition to Shao Tianlan's "geographical advantage", the timing of his association with robots also coincided with the "right time". In 2012, when he chose to study in Germany, the technologies and concepts in the domestic robot industry were still unable to be implemented at low cost, and the market was in its infancy.

Four years later, Shao Tianlan returned from his studies, but he happened to catch up with the development of domestic robots. Thanks to the rapid development of artificial intelligence technology, the industrial robot market has grown 10 times in 2016 compared with 10 years ago and has entered a stage of rapid development. It is a good time to start a business.

"Compared with foreign countries, China's market has two characteristics: First, the pace is faster; second, capital is more active and competition is more intense. It takes 10 years for others to develop, but we will achieve it in 3 years Catching up is like installing an accelerator." Shao Tianlan pointed out that although the market will experience some chaos and disorderly competition during the development of the industry, the good news is that the number and quality of engineers in our country are currently rising, which is compared with foreign markets. A big advantage.

The "China Robot Industry Development Report (2021)" also shows that China will occupy nearly 40% of the global robot market in 2021. Among them, industrial robots will account for 53% of China’s robot market, reaching 44.6 billion yuan. The latest data released by the Bureau of Statistics shows that China’s industrial robot production in the first ten months of 2021 has increased by 26% compared with the full-year production in 2020.

"This is a rapidly growing market, and the potential is visible to the naked eye." Shao Tianlan's tone contained a hint of longing and excitement. Obviously, he and his robot were ready to flex their muscles in the market.

02

Equip eyes and brains to the robot

Mecamander was officially established in 2016. The three founders of the start-up team are all from Tsinghua, and the engineering team also comes from Tsinghua, MIT, Carnegie Mellon, California Institute of Technology, University of Tokyo, etc. Top universities at home and abroad with profound technical strength. In 2022, it was selected as the national-level specialized and new "little giant" enterprise selected by the Ministry of Industry and Information Technology.

Since its establishment, the company has gone through four stages: technology accumulation, product implementation and application, product iteration and scale, and market globalization.

“The technical chain of intelligent industrial robots is extremely long, and there is no ‘unique skill’ in the industry. Development must be accumulated step by step,” he said. “The first stage is actually focused on developing core technologies, and there are no shortcuts; The painful part is still the second stage. We have to make the product come out of the laboratory and become a product that can be implemented and truly meet the needs of customers. This means that we have to clarify the needs with customers and polish the product over and over again. This Things can't be done in the laboratory." Shao Tianlan said with emotion that only when the products on the market are immature, customers will be willing to be patient and accompany the company to improve, "We have caught up with a good opportunity. .”

After the product was launched, in 2019, Mecamander entered the stage of large-scale application. During this period, the company improved internal efficiency while broadening its customer base, forming economies of scale. In 3 years, Mecamander has been implemented in nearly 2,000 cases in domestic logistics, automobile, heavy industry, home appliances and other industries. In the second half of 2021, Mecamand entered a period of globalization and established branches in Munich, Germany, Tokyo, Japan, and Chicago, the United States. It is expected that overseas business will achieve 100% growth in 2023. At present, Mecamander’s main products include industrial-grade high-precision 3D cameras, visual programming visual algorithm software and deep learning platform software, etc., mainly focusing on the field of machine vision. The technology revolves around sensing, perception, and planning. At the core The devices have been fully self-developed and produced, and more than 350 patents have been authorized and applied for. "Robots move in a three-dimensional space, so 3D vision has inherent advantages." Shao Tianlan introduced that in order to enable the robot to have a 3D field of view, Mecamander has developed a high-performance robot with fast speed, good imaging effect, and strong anti-interference ability. 3D cameras can output high-quality point cloud data for many types of objects; there are also a variety of camera models that can meet the diverse needs of ambient light resistance, high precision, high speed, and small size in different scenes.

"Although 99% of the current work can only be undertaken by humans, by giving robots 'eyes', the application scenarios of the robot industry have been greatly broadened. For example,

100 things In the past, the robot could only do one thing, but through 3D vision, we have been able to make the robot do 10 things." Shao Tianlan pointed out that if new scenes cannot be unlocked, the ceiling of the robot industry is actually very low. "Accelerating the expansion of robot application scenarios is an important innovation that Mecamander brings to the industry."

With the help of 3D vision cameras and artificial intelligence technology, currently, AI 3D industrial robot solutions have been implemented in the fields of automobiles, logistics, engineering machinery, 3C, new energy and other fields. The application scope covers disordered workpiece loading and unloading, cartons/sacks/ Depalletizing and palletizing of turnover boxes, high-precision positioning and assembly, industrial inspection/measurement, gluing, etc.

03Adhere to the standardized product route

Today, Mecamander has grown into a "unicorn" company in the field of industrial robots, with 3,000 implementation cases, and its business covers more than 50 countries and regions including China, Germany, Japan, the United States, and Australia. The company has received multiple rounds of support from many well-known investment institutions such as IDG Capital, Meituan, Sequoia China, Source Code Capital, Intel Capital, Qiming Venture Partners, etc., with cumulative financing exceeding 1.5 billion yuan.

Good results are inseparable from the correct corporate strategy. Mecamand's long-term strategy is to adhere to the route of standardized products and strive to become a world-leading intelligent robot infrastructure product company, supporting many companies in different directions and creating Various intelligent robot applications.

However, compared with companies that do integration projects in the field of robotics, the standardized product route chosen by the company has problems such as difficulty in acquiring customers, long profit cycle, and brutal market competition. It is a more difficult "road" to follow. ".

On the one hand, product standardization has higher technical requirements. In addition to the many and complex demands for industrial automation, there are also many processes in thousands of industries, and each process requires different automation. , Hardware standardization is difficult; on the other hand, the natural attributes of product standardization have led to greater competition in the industry. Usually only 1-3 leading companies in a field can survive, such as Gree, Midea, and Haier in the air-conditioning field. .

“Our approach is to transfer complexity from hardware to software as much as possible, using artificial intelligence technology, advanced vision and standardized hardware (i.e. robotic arms) to solve highly complex and non-standardized automation needs ." Shao Tianlan said, "This path was chosen because the results derived from business logic show that this is the only feasible route."

According to data, there are three core points in business logic: The first is value proposition, that is, the company's products or behaviors create value; The second is efficiency, the boundaries of the company's business must be Promote the efficiency improvement of the overall industrial chain rather than decrease;The third is comparative advantage, that is, the company's strength is advantageous in comparison.

"We are a high-tech product company that is good at solving technical problems. Our downstream partners are very good at analyzing and understanding customer needs in segmented fields, as well as controlling non-standard solutions and costs. We work together with them to achieve It can achieve high technology and low cost at the same time." Shao Tianlan pointed out that the core problem of high-tech companies is the amortization of R&D and sales expenses. Due to the huge investment in continuous R&D, if companies do things they are not good at at the same time, they will not be able to achieve high market share. share, which in turn cannot form a positive business cycle. "If we do what they do, it will be of no benefit to either of us - they can't achieve high technology, and we can't achieve low cost."

Shao Tianlan said that he often compares starting a business to an instrument landing, which means that if you fly an airplane, even if you encounter heavy fog and the visibility is 0, you can use the instrument landing system on the airplane, that is, the instrument data. And airborne receiving equipment can actually achieve safe landing. But the premise is that the pilot must believe in the dashboard - this is reflected in entrepreneurship, which means believing in logic and rules.

"Although being in an unknown environment is scary, as long as you believe in logic, the road can still be navigated. After all, if you can't understand the business logic, how can you lead the company to success?"

Summary

The process of industrial automation started in the 1960s. After more than half a century of development, the previous industrial robot industry was dominated by four companies: Japan's FANUC, YASKAWA, Switzerland's ABB, and Germany's KUKA. Global industrial robots account for more than 50% of the market share, and they also account for about 60% of the Chinese market.

However, in today's manufacturing factories, there are still a large number of links that are not automated. This is exactly the angle that Mecamander chose to enter - leaving complex problems to software to solve, letting AI 3D vision technology become the brain and eyes of the robot, and combining standardized hardware to complete loading and unloading. , inspection, screw tightening, cutting, welding and other complex tasks.

Among them, Mecamander gives robots "eyes", which directly raises the ceiling of the robot industry, greatly broadens the application scenarios of intelligent robots, greatly promotes the market popularity of intelligent robots, and has a great influence on the development of the industry. far-reaching significance.

According to the research report of the High-tech Robot Industry Research Institute and Rui Industry, in 2020 and 2021, Mecamander has achieved a leading market share in the field of 3D visual guidance of Chinese robots for two consecutive years. In addition to market share, as a leader in the intelligent robot industry, Mecamander is also among the best in terms of implementation cases and technology chains. It has core competitiveness, innovative spirit and market potential.

The above is the detailed content of Single-handedly raising the ceiling of the industry, he sold robots to more than 50 countries. For more information, please follow other related articles on the PHP Chinese website!

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AM

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AMThis article explores the growing concern of "AI agency decay"—the gradual decline in our ability to think and decide independently. This is especially crucial for business leaders navigating the increasingly automated world while retainin

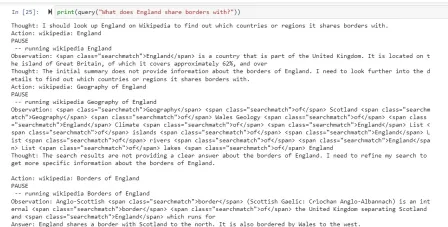

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AM

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AMEver wondered how AI agents like Siri and Alexa work? These intelligent systems are becoming more important in our daily lives. This article introduces the ReAct pattern, a method that enhances AI agents by combining reasoning an

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM"I think AI tools are changing the learning opportunities for college students. We believe in developing students in core courses, but more and more people also want to get a perspective of computational and statistical thinking," said University of Chicago President Paul Alivisatos in an interview with Deloitte Nitin Mittal at the Davos Forum in January. He believes that people will have to become creators and co-creators of AI, which means that learning and other aspects need to adapt to some major changes. Digital intelligence and critical thinking Professor Alexa Joubin of George Washington University described artificial intelligence as a “heuristic tool” in the humanities and explores how it changes

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AM

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AMLangChain is a powerful toolkit for building sophisticated AI applications. Its agent architecture is particularly noteworthy, allowing developers to create intelligent systems capable of independent reasoning, decision-making, and action. This expl

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AM

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AMRadial Basis Function Neural Networks (RBFNNs): A Comprehensive Guide Radial Basis Function Neural Networks (RBFNNs) are a powerful type of neural network architecture that leverages radial basis functions for activation. Their unique structure make

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AM

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AMBrain-computer interfaces (BCIs) directly link the brain to external devices, translating brain impulses into actions without physical movement. This technology utilizes implanted sensors to capture brain signals, converting them into digital comman

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AM

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AMThis "Leading with Data" episode features Ines Montani, co-founder and CEO of Explosion AI, and co-developer of spaCy and Prodigy. Ines offers expert insights into the evolution of these tools, Explosion's unique business model, and the tr

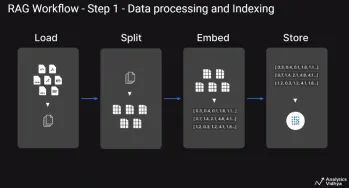

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AM

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AMThis article explores Retrieval Augmented Generation (RAG) systems and how AI agents can enhance their capabilities. Traditional RAG systems, while useful for leveraging custom enterprise data, suffer from limitations such as a lack of real-time dat

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.