Technology peripherals

Technology peripherals AI

AI A variety of construction robots show their talents on the construction site

A variety of construction robots show their talents on the construction siteA variety of construction robots show their talents on the construction site

The brick-laying and transporting robot is moving bricks.

Photographed by Li Can

Concrete wall polishing robot.

Photographed by Changjiang Daily reporter Zhang Zhi

Changjiang Daily News (Reporter Zhang Zhi, Correspondent Liu Tao and Cui Dongyue) A variety of construction robots entered the construction site to show off their skills: On June 2, at the construction site of the China Urban and Rural Headquarters Economic Industrial Park in Wuhan Economic Development Zone, the average brick-moving robot could To move 3.6 cubic meters of bricks, the work efficiency is comparable to that of 4-6 workers.

China Urban and Rural has built a headquarters base on the bank of Houguan Lake in Wuhan Economic Development Zone. This is an economic and industrial park project of China Urban and Rural state-owned enterprises in Han. Among them, the project plans to build a 188-meter-high headquarters building, which will be constructed by China Communications Construction Group Co., Ltd.

In April this year, CCCC Construction’s China Urban and Rural Headquarters Economic Industrial Park project spent more than 700,000 yuan to introduce three construction robots to replace labor. They were used to carry bricks, polish internal concrete walls, and seal screw holes. After nearly two months of "actual" testing, the three construction robots not only improved work efficiency, reduced workers' labor intensity, shortened the project construction period, but also effectively reduced dust, noise and other environmental pollution and safety hazards. The person in charge of the Wuhan Construction Engineering Safety Supervision Station said that construction robots are widely used in Wuhan's construction engineering field, and the engineering construction in this park is the first pilot project.

On the 2nd, a reporter from Yangtze River Daily saw at the construction site of the project that a pink brick-laying robot picked up 24 stacked bricks at one time and moved the bricks in parallel according to the set program. Go to the location set by the system and put it down gently, saving the manual process of loading and unloading bricks. According to on-site technicians, the brick-laying handling robot has functions such as visual recognition, automatic loading of bricks, automatic taking the elevator upstairs, and automatic loading of bricks, which greatly improves the work efficiency of heavy processes, saves manpower and shortens the construction period.

Guo Jingang, project manager of the China Urban and Rural Headquarters Economic Industrial Park of CCCC Construction, pointed out that the bricklaying work of the project was previously carried out by construction workers using bucket trucks. First transport the bricks to the bucket truck, then attach the cart to the elevator to go upstairs, and finally reach the target floor and place the bricks. The bucket truck can transport up to 7 bricks at a time. During the brick loading and unloading process, there is not only loss, but also environmental pollution problems such as dust and noise. After we introduced the robot, we arranged for the brick-moving robot to work at night and transport the bricks to the designated location in advance. After going to work the next day, workers can start construction directly, which greatly shortens the construction period. ”

Guo Jingang said that after using the "brick-moving robot" at the construction site, it can work 24 hours a day. In addition to the investment of one-time equipment, it only requires 7 kilowatt hours of electricity for 6 to 8 hours of full load operation. Equipped with 2 batteries, it can basically achieve all-day construction.

In the past, workers had to polish concrete walls, using ladders for high-altitude parts, and the smoothness of the polished wall completely relied on the skills of the workers. A concrete internal wall polishing robot is used, which can automatically lift and carry out construction at a height of up to 3.2 meters, while ensuring that the wall flatness error is within 2 mm. A screw hole sealing robot can block 100 screw holes per hour on average, which is equivalent to the workload of 8-10 workers for one hour. The sealing construction is accurate and there is basically no need for rework.

According to Guo Jingang, preliminary calculations show that the cost and benefit of using three construction robots are equivalent to those of manual labor, which made the project department aware of the advantages of intelligent construction. In the future, the project also plans to introduce a variety of robots such as wall plastering robots, screw bracket installation robots, indoor spraying robots, wall tile paving robots, and exterior wall spraying robots to free workers from heavy physical labor. Use green and low-carbon digital intelligence technology concepts to empower project safety and quality standardization construction.

Source: Changjiang Daily

The above is the detailed content of A variety of construction robots show their talents on the construction site. For more information, please follow other related articles on the PHP Chinese website!

What is Few-Shot Prompting? - Analytics VidhyaApr 22, 2025 am 09:13 AM

What is Few-Shot Prompting? - Analytics VidhyaApr 22, 2025 am 09:13 AMFew-Shot Prompting: A Powerful Technique in Machine Learning In the realm of machine learning, achieving accurate responses with minimal data is paramount. Few-shot prompting offers a highly effective solution, enabling AI models to perform specific

What is Temperature in prompt engineering? - Analytics VidhyaApr 22, 2025 am 09:11 AM

What is Temperature in prompt engineering? - Analytics VidhyaApr 22, 2025 am 09:11 AMPrompt Engineering: Mastering the "Temperature" Parameter for AI Text Generation Prompt engineering is crucial when working with large language models (LLMs) like GPT-4. A key parameter in prompt engineering is "temperature," whi

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AM

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AMThis article explores the growing concern of "AI agency decay"—the gradual decline in our ability to think and decide independently. This is especially crucial for business leaders navigating the increasingly automated world while retainin

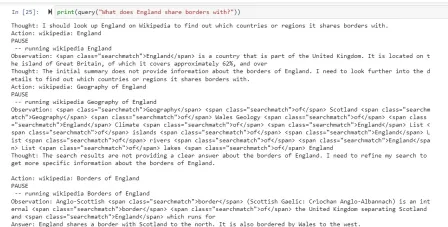

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AM

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AMEver wondered how AI agents like Siri and Alexa work? These intelligent systems are becoming more important in our daily lives. This article introduces the ReAct pattern, a method that enhances AI agents by combining reasoning an

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM"I think AI tools are changing the learning opportunities for college students. We believe in developing students in core courses, but more and more people also want to get a perspective of computational and statistical thinking," said University of Chicago President Paul Alivisatos in an interview with Deloitte Nitin Mittal at the Davos Forum in January. He believes that people will have to become creators and co-creators of AI, which means that learning and other aspects need to adapt to some major changes. Digital intelligence and critical thinking Professor Alexa Joubin of George Washington University described artificial intelligence as a “heuristic tool” in the humanities and explores how it changes

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AM

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AMLangChain is a powerful toolkit for building sophisticated AI applications. Its agent architecture is particularly noteworthy, allowing developers to create intelligent systems capable of independent reasoning, decision-making, and action. This expl

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AM

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AMRadial Basis Function Neural Networks (RBFNNs): A Comprehensive Guide Radial Basis Function Neural Networks (RBFNNs) are a powerful type of neural network architecture that leverages radial basis functions for activation. Their unique structure make

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AM

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AMBrain-computer interfaces (BCIs) directly link the brain to external devices, translating brain impulses into actions without physical movement. This technology utilizes implanted sensors to capture brain signals, converting them into digital comman

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

Dreamweaver Mac version

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool

WebStorm Mac version

Useful JavaScript development tools