Technology peripherals

Technology peripherals AI

AI Important manufacturing trends: Intelligent robots need four capabilities

Important manufacturing trends: Intelligent robots need four capabilitiesImportant manufacturing trends: Intelligent robots need four capabilities

Intelligent robots are typical representatives of intelligent products. Intelligent robots must have at least the following three elements: first, the sensing element, used to understand the state of the surrounding environment; second, the movement element, to make reactive actions to the outside world; third, the thinking element, based on the information obtained from the sensing element, think and adopt What kind of action.

People usually divide robots into three generations. The first generation is programmable robots. This kind of robot can generally complete some simple repetitive operations according to the program programmed by the operator. This generation of robots has been put into use since the second half of the 1960s and is now widely used in industry.

The second generation is a perceptual robot, also called an adaptive robot. It is developed on the basis of the first generation robot and has varying degrees of ability to perceive the surrounding environment.

The third generation robot has intelligent mechanisms such as recognition, reasoning, planning and learning. It can intelligently combine perception and action, so it can operate in non-specific environments and is called an intelligent robot.

The fundamental difference between intelligent robots and industrial robots is that intelligent robots have the functions of perception, identification, judgment and planning. Therefore, the intelligence of machines can be divided into two levels. One is the ability to perceive, identify, understand and judge. Function, the second is the function of summarizing experience and learning.

Intelligent robots have different system structures and functions due to their different uses. Here we only introduce the basic structure and intelligent characteristics of robots for industrial applications. Figure 2.3 is the basic structure of an intelligent robot.

▲Figure 2.3 The basic composition of intelligent robots

1. Environment perception ability

The most significant intelligent feature of intelligent robots is external and Internal perception.

The external environment perception capability is realized by the external perception system, which uses a series of external sensors (including vision, hearing, touch, proximity, force, infrared, ultrasound, laser, etc.) to process sensing information. Implement control and operation. These sensors include collision sensors, far-infrared sensors, photosensitive sensors, microphones, photoelectric encoders, pyroelectric sensors, ultrasonic sensors, continuous ranging infrared sensors, digital compasses, temperature sensors, etc.

The internal perception system consists of a series of sensors used to detect the status of the robot itself. It can monitor the position, speed, acceleration, pressure and trajectory of each coordinate of each moving part of the robot in real time, and monitor the stress of each component. Force, balance, temperature, etc.

The intelligent perception system consists of information obtained from the external environment perception system and the internal perception system. There are more and more types and numbers of sensors used in this system. Each sensor has certain usage conditions and sensing range, and can provide information about part or the entire side of the environment or object. In order to effectively utilize this sensor information , it is necessary to use some form of synthesis or fusion processing of sensor information. A multi-form processing system for different types of information is sensor fusion.

Sensor fusion technology involves new theories and methods in the fields of information, detection and control such as neural networks, knowledge engineering, and fuzzy theory.

2. Control capability

The system control capability of the intelligent robot is realized by the intelligent control system. The task of the system is to control the system according to the robot's operation instruction program and the signals fed back from internal and external sensors. The knowledge base and expert system identify and apply different algorithm analysis and decision-making, and then issue control instructions to control the robot to complete specified movements and functions.

If the robot does not have information feedback characteristics, the robot's control system is an open-loop control system, otherwise it is a closed-loop control system. According to the control principle, the control system can be divided into program control system, adaptive control system and artificial intelligence control system. According to the form of control movement, the control system can be divided into point control system and continuous trajectory control system.

How to analyze and process this information and make correct control decisions requires the support of an expert system. The expert system interprets the data collected from the sensors, derives a description of the robot's state, deduce and predict possible results from the given state, and diagnoses possible system faults through the evaluation of the operating state.

According to the goals and constraints of the system design, plan and design a series of actions, monitor the differences between the results obtained and the plan, and propose methods to maintain the correct operation of the system. The artificial intelligence system is combined with traditional control methods to form the entire closed-loop control process, which requires the support of a large amount of knowledge, rules, algorithms, pattern recognition and other technologies.

3. Learning ability

As the requirements for intelligent robots continue to increase, the environment faced by robots is often unpredictable, and unstructured environments have become mainstream. In a dynamic and complex environment, if a robot wants to complete complex tasks, its learning ability is extremely important.

In this case, the robot should continuously adjust itself through learning according to the external environment and tasks it faces, and extract useful information during the process of interacting with the environment, so that it can gradually understand and adapt to the environment. Through learning, the intelligence level of the robot can be continuously improved, allowing it to cope with some unexpected situations, thereby making up for possible deficiencies caused by designers during the design process.

Therefore, learning ability is one of the important abilities that robots should have. It provides effective guarantee for robots in complex and changeable environments in terms of environmental understanding, planning and decision-making, thereby improving the operation of the entire robot system. efficiency.

4. The ability to access the Industrial Internet

Smart robots, like all smart products, will become a terminal of the Industrial Internet in the future, so smart robots must have the ability to access the Industrial Internet.

Using the principle of cyber-physical fusion system (CPS) to build a communication module, internally integrated with the intelligent control system to collect all operating status of the robot; externally connected to the Internet through a standard fieldbus and Ethernet card to realize the robot's The integration between robots and logistics systems and other application systems realizes the integration between the physical world and the information world.

The intelligent IoT system breaks the boundaries between the traditional physical world and information systems, turning data into timely and useful information, allowing users to fully enjoy various resources in the virtual and real worlds.

This article is excerpted from "Intelligent Manufacturing: How AI Implements Manufacturing" (ISBN: 978-7-111-69931-6), and is published with the authorization of the publisher.

The above is the detailed content of Important manufacturing trends: Intelligent robots need four capabilities. For more information, please follow other related articles on the PHP Chinese website!

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AM

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AMThis article explores the growing concern of "AI agency decay"—the gradual decline in our ability to think and decide independently. This is especially crucial for business leaders navigating the increasingly automated world while retainin

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AM

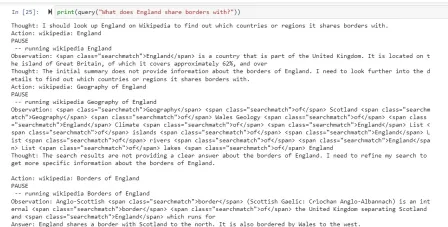

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AMEver wondered how AI agents like Siri and Alexa work? These intelligent systems are becoming more important in our daily lives. This article introduces the ReAct pattern, a method that enhances AI agents by combining reasoning an

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM"I think AI tools are changing the learning opportunities for college students. We believe in developing students in core courses, but more and more people also want to get a perspective of computational and statistical thinking," said University of Chicago President Paul Alivisatos in an interview with Deloitte Nitin Mittal at the Davos Forum in January. He believes that people will have to become creators and co-creators of AI, which means that learning and other aspects need to adapt to some major changes. Digital intelligence and critical thinking Professor Alexa Joubin of George Washington University described artificial intelligence as a “heuristic tool” in the humanities and explores how it changes

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AM

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AMLangChain is a powerful toolkit for building sophisticated AI applications. Its agent architecture is particularly noteworthy, allowing developers to create intelligent systems capable of independent reasoning, decision-making, and action. This expl

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AM

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AMRadial Basis Function Neural Networks (RBFNNs): A Comprehensive Guide Radial Basis Function Neural Networks (RBFNNs) are a powerful type of neural network architecture that leverages radial basis functions for activation. Their unique structure make

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AM

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AMBrain-computer interfaces (BCIs) directly link the brain to external devices, translating brain impulses into actions without physical movement. This technology utilizes implanted sensors to capture brain signals, converting them into digital comman

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AM

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AMThis "Leading with Data" episode features Ines Montani, co-founder and CEO of Explosion AI, and co-developer of spaCy and Prodigy. Ines offers expert insights into the evolution of these tools, Explosion's unique business model, and the tr

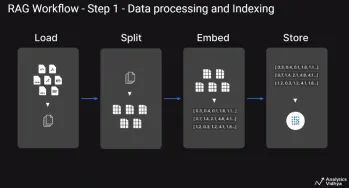

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AM

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AMThis article explores Retrieval Augmented Generation (RAG) systems and how AI agents can enhance their capabilities. Traditional RAG systems, while useful for leveraging custom enterprise data, suffer from limitations such as a lack of real-time dat

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

Dreamweaver Mac version

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool

WebStorm Mac version

Useful JavaScript development tools