Six major trends and prospects in the industrial robot industry

External factors have had a huge impact on the industrial robotics industry in recent years, from the COVID-19 pandemic to geopolitical tensions and supply chain disruptions.

At the same time, internal factors such as technological and usability advances also have an impact on the development and adoption of industrial robots.

Whether you are new to industrial automation or a veteran with decades of experience, there is an overwhelming amount of information to sift through, making identifying the most impactful industry trends a real challenge.

So, as 2022 comes to an end, what trends do those in the industrial robotics industry need to pay attention to?

1. Workforce and Demographics

Scott Marsic, robotics product manager for Epson America, said labor shortages are the most important trend driving the adoption of industrial automation.

Kary Zate, senior director of marketing communications at warehouse automation service provider Locus Robotics, said, "The manufacturing industry in the United States is developing very well, but the shortage of employees has become a major problem."

The labor shortage problem is a global problem sexual.

Zate said, “Due to the labor shortage and the aging workforce in the warehousing industry, the younger generation is not interested in working in a warehouse environment because, frankly, it is a hard job that requires workers to be on duty every day. Warehouses walk 10 to 15 kilometers to transport and dispatch goods. Such work is very arduous."

He explained that as finding and retaining talents has become a major challenge facing various industries, more and more companies are starting to Turn to industrial automation to fill labor gaps, increase productivity, and remain competitive in a challenging macroeconomic environment.

2. Digital drive

Lian Jye Su, research director of market analysis agency ABI Research, said that the new crown epidemic has accelerated the adoption of automation and digital transformation in the industrial sector.

Su said, "This trend includes remote monitoring software and software that can promote the adoption of industrial automation in other ways." He cited READY Robotics' robot operating system and RoboDK's offline programming software as examples.

He said, "There is no faster way to automate than using these types of software, especially when deploying multiple robots. The traditional approach is to hire engineers to debug the robot solution, but this may require Weeks or even months, this means that many manufacturers missed the opportunity."

Marsic of Epson said that if you attend any industry exhibition, you will find a variety of digital tools, ranging from artificial intelligence and augmented reality to digital twins for manufacturing applications.

Marsic said, “This is an exciting era for robotics and digitization, and these technologies are helping to attract new talent into robotics programming positions. For programmers, there are opportunities to work with artificial intelligence and augmented reality technologies Collaboration is very cool,” said Lian Jye Su of ABI Research. Robots remain the fastest growing segment of the industrial robotics sector.

He said, "In recent years, there has been a lot of positive feedback about the ease of deployment of collaborative robots. Over time, collaborative robots have found their place in the industrial robot field and have proven Can complement workers and traditional industrial robots. I don't see its growth slowing down anytime soon."

According to ABI Research, the global market size of the collaborative robot market in 2020 was approximately $475 million. , growing to US$600 million in 2021, and is expected to reach US$8 billion by 2030, with an expected compound annual growth rate of 32.5%.

Meanwhile, the popularity of mobile robots is also rising rapidly, Su said: "Just 10 years ago, mobile robots were a luxury product, and now, from deep-sea oil drilling platforms to manufacturing and Warehousing facilities, they are found in almost every industry field and location."

According to data released by ABI Research, global robotics venture capital investment will reach US$5.7 billion in 2021, a year-on-year increase of 38%. Autonomous mobile robots It has attracted huge interest from industry users.

4. Manufacturing reshoring plan

Overseas labor costs are rising rapidly, and at the same time, automation costs are falling significantly. Epson's Masic said these are just two of the factors driving reshoring plans in the U.S. and other major economies.

He said, "Today, there are several additional issues to contend with, from intellectual property and tariffs to geopolitics, as well as supply chain challenges. The United States needs to quickly restore manufacturing and the best way to achieve this is It’s automation, especially during labor shortages.”

By shortening supply chains, reshoring programs can also reduce carbon emissions, generate environmental benefits and help make manufacturing more sustainable.

5. Lowering Barriers

The increasing availability of industrial robotic systems is making it easier than ever for businesses of all sizes and technology levels to deploy automation.

Epson’s Masic said: “The pursuit of simplicity is a very important trend. People want to get their automation systems up and running quickly. This requires an easy-to-use operating system and extensive customer support throughout the process.” The need for simplicity is driven by new customers and new users entering the automation space. We were seeing this trend before COVID-19." LocusRobotics' Zate said the "robots as a service" model is increasingly More popular, this makes automation adoption easier and less capital intensive, allowing operators to seamlessly scale in minutes to meet changing volumes and seasonal peaks.

6. Focus on sustainability

Masic said robot manufacturers and their customers are increasingly paying attention to sustainability and climate issues.

He said, "Sustainable development and environmental responsibility have always been Epson's core values. For example, by being as energy-efficient and environmentally friendly as possible and exploring the entire life cycle of our products to discover which parts can be reused."

Zate said that from the beginning, Locus Robotics developed its business model based on sustainability principles, including extensive refurbishing of parts.

He said, “We like to say, ‘Robots will never die.’ We have always valued sustainability and it is part of our corporate culture. Today, sustainable manufacturing has a strong role in the robotics industry and among our customers. "Robots as a service" is a key component of Locus Robotics' sustainability mission, Zate added, "because our robots can be refurbished and we can repair them, Upgrading them with new hardware and software. This means our customers have the latest and greatest automation equipment at all times.”

The above is the detailed content of Six major trends and prospects in the industrial robot industry. For more information, please follow other related articles on the PHP Chinese website!

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AM

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AMThis article explores the growing concern of "AI agency decay"—the gradual decline in our ability to think and decide independently. This is especially crucial for business leaders navigating the increasingly automated world while retainin

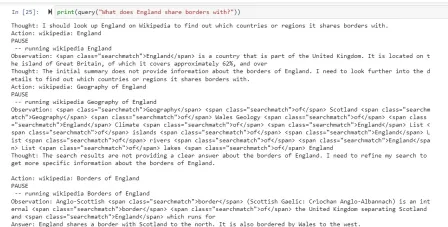

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AM

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AMEver wondered how AI agents like Siri and Alexa work? These intelligent systems are becoming more important in our daily lives. This article introduces the ReAct pattern, a method that enhances AI agents by combining reasoning an

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM"I think AI tools are changing the learning opportunities for college students. We believe in developing students in core courses, but more and more people also want to get a perspective of computational and statistical thinking," said University of Chicago President Paul Alivisatos in an interview with Deloitte Nitin Mittal at the Davos Forum in January. He believes that people will have to become creators and co-creators of AI, which means that learning and other aspects need to adapt to some major changes. Digital intelligence and critical thinking Professor Alexa Joubin of George Washington University described artificial intelligence as a “heuristic tool” in the humanities and explores how it changes

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AM

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AMLangChain is a powerful toolkit for building sophisticated AI applications. Its agent architecture is particularly noteworthy, allowing developers to create intelligent systems capable of independent reasoning, decision-making, and action. This expl

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AM

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AMRadial Basis Function Neural Networks (RBFNNs): A Comprehensive Guide Radial Basis Function Neural Networks (RBFNNs) are a powerful type of neural network architecture that leverages radial basis functions for activation. Their unique structure make

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AM

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AMBrain-computer interfaces (BCIs) directly link the brain to external devices, translating brain impulses into actions without physical movement. This technology utilizes implanted sensors to capture brain signals, converting them into digital comman

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AM

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AMThis "Leading with Data" episode features Ines Montani, co-founder and CEO of Explosion AI, and co-developer of spaCy and Prodigy. Ines offers expert insights into the evolution of these tools, Explosion's unique business model, and the tr

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AM

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AMThis article explores Retrieval Augmented Generation (RAG) systems and how AI agents can enhance their capabilities. Traditional RAG systems, while useful for leveraging custom enterprise data, suffer from limitations such as a lack of real-time dat

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.

WebStorm Mac version

Useful JavaScript development tools

Atom editor mac version download

The most popular open source editor

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software