P&G turns to artificial intelligence for digital manufacturing

After 184 years of development, Procter & Gamble (P&G) has grown into one of the world's largest consumer goods manufacturers. By 2021, its global revenue will exceed US$76 billion, and its employees More than 100,000 people. Its brands are household names, including Charmin, Crest, Dawn, Febreze, Gillette, Olay, Pampers and Tide.

In the summer of 2022, P&G entered into a multi-year partnership with Microsoft to transform its digital manufacturing platform. Microsoft stated that they will use the industrial Internet of Things, digital twins, data and artificial intelligence to provide P&G with faster product delivery, improve customer satisfaction, while increasing productivity and reducing costs, thereby creating the future of digital manufacturing.

Vittorio Cretella, Chief Information Officer of P&G, said, “The primary purpose of our digital transformation is to create outstanding solutions to the daily problems of millions of consumers around the world, while creating value for all stakeholders. To this end, We leverage technologies such as data, artificial intelligence and automation to increase agility in all aspects of our business while accelerating innovation and increasing productivity.” Check product quality, maximize equipment resiliency while avoiding waste, and optimize energy and water use in manufacturing plants. Cretella said P&G will make manufacturing smarter by enabling scalable predictive quality, predictive maintenance, controlled release, touchless operations and manufacturing sustainability optimization. Until now, he said, these things have not been done on this scale in manufacturing.

Intelligent Manufacturing at Scale

The company has launched pilot projects in Egypt, India, Japan and the United States using Azure IoT Hub and IoT Edge to help manufacturing technicians analyze insights to improve infant care and production of paper products.

For example, the production of diapers involves assembling multiple layers of materials at high speed and precision to ensure optimal absorbency, leakage resistance and comfort. The new Industrial IoT platform uses machine telemetry and high-speed analytics to continuously monitor production lines to provide early detection and prevention of potential problems in the flow of materials. This in turn improves cycle times, reduces network losses and ensures quality while increasing operator productivity.

P&G is also piloting the use of industrial IoT, advanced algorithms, machine learning and predictive analytics to improve productivity in tissue production. P&G can now better predict the length of finished paper towels.

Large-scale smart manufacturing is a challenge. It requires acquiring data from equipment sensors, applying advanced analytics to derive descriptive and predictive insights, and automating corrective actions. The end-to-end process requires several steps, including data integration and algorithm development, training, and deployment. It also involves large amounts of data and near real-time processing.

Cretella said, "The secret to scale is to reduce complexity by providing common components at the edge and in the Microsoft cloud, which engineers can use to deploy different use cases to specific manufacturing environments - and No need to create everything from scratch."

Using Microsoft Azure as a foundation, P&G is now able to digitize and integrate data from more than 100 manufacturing sites around the world and enhance real-time capabilities with artificial intelligence, machine learning and edge computing services Visibility. This, in turn, will enable P&G employees to analyze production data and leverage artificial intelligence to support decisions that drive improvements and exponential impact.

Acquisition of this level of data at scale is rare in the consumer goods industry, Cretella added.

Data and artificial intelligence are the foundation of digital

In fact, P&G took the first step in the artificial intelligence journey more than five years ago. It has passed what Cretella calls an "experimental phase," with solutions at scale and increasingly sophisticated AI applications. Data and artificial intelligence have since become central to the company's digital strategy.

Cretella said, “We use artificial intelligence in all aspects of our business to predict outcomes and increasingly take action through automation. In addition, we also have applications in the area of product innovation, through modeling and simulation , we can shorten the time to develop new formulas from months to weeks; use artificial intelligence to deliver brand information to every consumer at the right time, in the right channel, and with the right content. P&G engineers also use Azure AI To ensure quality control and equipment resiliency on the production line.”

P&G’s secret to scale relies on technology, including investing in a scalable data and artificial intelligence environment centered on a cross-functional data lake, Cretella said, P&G Another hidden secret relies on the skills of hundreds of talented data scientists and engineers who know the company's business inside and out. To that end, P&G's future will embrace AI automation, which will free its data engineers, data scientists, and machine learning engineers from manual, labor-intensive tasks, allowing them to focus more on other areas where they can add value.

Cretella added that AI-powered automation also enables us to deliver consistent quality and manage deviations and risks. Additionally, AI automation will enable an increasing number of employees to take advantage of these capabilities, making the benefits of AI pervasive throughout the company.

Leveraging the Power of People

Another element of achieving agility at scale is P&G’s “hybrid” approach to building teams within IT teams. P&G balances the organization between central teams and teams embedded in its categories and markets. Central teams create enterprise platforms and technology foundations, while embedded teams use these platforms and foundations to build digital solutions that capture business opportunities specific to their departments. Cretella also noted that the company prioritizes internal talent, particularly in areas such as data science, cloud management, cybersecurity, software engineering and DevOps.

To accelerate P&G’s transformation, Microsoft and P&G established a Digital Enablement Office (DEO) composed of experts from both organizations. The DEO will serve as an incubator to create high-priority business scenarios in the areas of product manufacturing and packaging processes that can be implemented across P&G. Cretella considers it more of a project management office than a center of excellence. Because it coordinates the efforts of all the different innovation teams working on business use cases and ensures effective scaling deployment of the developed proven solutions.

Finally, Cretella had some advice for CIOs trying to drive digital transformation in their own businesses: First, be motivated and find your energy in your passion for the business and how to apply technology to create value; Second, have the agility to learn and a true desire to learn; and finally, invest in people (your team, colleagues, and even your boss) because technology alone doesn’t change anything; talent is the key to everything.

The above is the detailed content of P&G turns to artificial intelligence for digital manufacturing. For more information, please follow other related articles on the PHP Chinese website!

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AM

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AMThis article explores the growing concern of "AI agency decay"—the gradual decline in our ability to think and decide independently. This is especially crucial for business leaders navigating the increasingly automated world while retainin

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AM

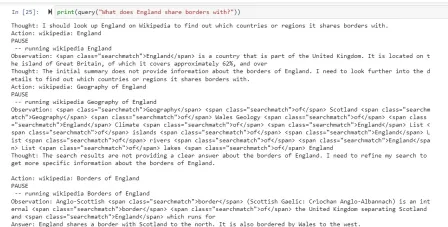

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AMEver wondered how AI agents like Siri and Alexa work? These intelligent systems are becoming more important in our daily lives. This article introduces the ReAct pattern, a method that enhances AI agents by combining reasoning an

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM"I think AI tools are changing the learning opportunities for college students. We believe in developing students in core courses, but more and more people also want to get a perspective of computational and statistical thinking," said University of Chicago President Paul Alivisatos in an interview with Deloitte Nitin Mittal at the Davos Forum in January. He believes that people will have to become creators and co-creators of AI, which means that learning and other aspects need to adapt to some major changes. Digital intelligence and critical thinking Professor Alexa Joubin of George Washington University described artificial intelligence as a “heuristic tool” in the humanities and explores how it changes

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AM

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AMLangChain is a powerful toolkit for building sophisticated AI applications. Its agent architecture is particularly noteworthy, allowing developers to create intelligent systems capable of independent reasoning, decision-making, and action. This expl

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AM

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AMRadial Basis Function Neural Networks (RBFNNs): A Comprehensive Guide Radial Basis Function Neural Networks (RBFNNs) are a powerful type of neural network architecture that leverages radial basis functions for activation. Their unique structure make

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AM

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AMBrain-computer interfaces (BCIs) directly link the brain to external devices, translating brain impulses into actions without physical movement. This technology utilizes implanted sensors to capture brain signals, converting them into digital comman

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AM

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AMThis "Leading with Data" episode features Ines Montani, co-founder and CEO of Explosion AI, and co-developer of spaCy and Prodigy. Ines offers expert insights into the evolution of these tools, Explosion's unique business model, and the tr

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AM

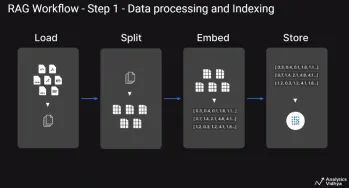

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AMThis article explores Retrieval Augmented Generation (RAG) systems and how AI agents can enhance their capabilities. Traditional RAG systems, while useful for leveraging custom enterprise data, suffer from limitations such as a lack of real-time dat

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.