Technology peripherals

Technology peripherals AI

AI Artificial Intelligence can help mitigate the top five risks suppliers face

Artificial Intelligence can help mitigate the top five risks suppliers faceArtificial Intelligence can help mitigate the top five risks suppliers face

Artificial intelligence is driving many changes in modern business. Many businesses are using AI technology to better understand their customers, identify ways to manage their finances more efficiently, and solve a number of other problems. Because AI has proven to be so valuable, 37% of companies said they already use AI technology. In reality, this number may be higher, as some companies do not realize that they may be using different forms of artificial intelligence.

Artificial intelligence is particularly helpful in managing risk. Many vendors are looking for ways to use artificial intelligence and data analytics more effectively.

How artificial intelligence can help suppliers better manage risks

For many years, artificial intelligence technology has been helping companies in different industry sectors. As ongoing economic issues create new challenges, artificial intelligence becomes even more valuable to businesses.

The benefits of adopting artificial intelligence stem from the need to manage close relationships with business stakeholders, which is a difficult task. All businesses need to develop complex relationships with a variety of suppliers and service providers to develop the products and services they offer their customers – but there is always some risk involved in preserving these relationships. Since the Russia-Ukraine conflict, the COVID-19 crisis, and other issues have exacerbated these risks, artificial intelligence has become increasingly important for companies looking to mitigate these risks.

Here are some of the risks businesses face when dealing with suppliers and what they can do to mitigate them using artificial intelligence.

(1) Failure or delay risk

Failure to deliver is one of the most common risks faced by companies in the past two years. This risk is best defined as a complete supply or service failure, which may be permanent or temporary.

There may be many localized or broad reasons for a supplier's failure to provide goods or services. For example, poor management could cause their business to collapse, eliminating their products from the supply chain. Material availability can lead to failure because suppliers are unable to manufacture products when they lack resources. Finally, unexpected or unavoidable events, such as disruptions to major trade routes or unprecedentedly severe storms, can cause catastrophic delays that shut down manufacturing or prevent trade in a region.

This is a problem that can be partially solved with artificial intelligence. Businesses can use predictive analytics tools to predict different events that may occur, and cloud-based applications can also help.

Google Cloud author Matt A.V. Chaban talked about this issue in a recent article. Hans Thalbauer, general manager of Google Cloud's supply chain and logistics business, said the company is using end-to-end data to better manage risks at different points in the supply chain to avoid failures.

(2)Brand Reputation Risk

Suppliers must be true to their mission and consider their reputation. Fortunately, artificial intelligence technology can make this situation easier.

There are several ways a company’s brand can be negatively impacted by members of its supply chain. If poor supplier practices lead to frequent product recalls, the businesses selling these products may be viewed by consumers as negligent and untrustworthy. Likewise, if a vendor releases information that contradicts a brand's marketing message, consumers may become confused or frustrated by the inconsistency in the partnership. As the internet sheds more light on supplier relationships and social media provides consumers with an outlet for advocacy, companies need to pay special attention to the brand reputation risks they face in their supply chains.

How can artificial intelligence help manage corporate brand reputation? Companies can leverage machine learning to drive automation and data mining tools to continue to study the representations made by members of their supply chain and their customers. This will help businesses identify issues that must be corrected.

(3) Competitive advantage risk

Businesses that rely on the uniqueness of their intellectual property face risks when working with suppliers who may sell their intellectual property, counterfeit goods, or otherwise Enter the market with similar products.

Market saturation requires companies to develop some kind of unique selling proposition that provides them with a competitive advantage. Unfortunately, the power of this competitive advantage can be diminished if companies choose to work with untrustworthy suppliers. In other countries, where the rules regarding intellectual property are less stringent, suppliers may be interested in generating additional revenue by collaborating with a business's competitors to provide information about secret or special intellectual property. While the supply chain itself may not be harmed by this risk, such supplier behavior could undermine a business's strategy and cause it to fail.

Artificial intelligence technology can help suppliers improve competitive risks in a variety of ways. They can save money through automation technology, identify more cost-effective ways to transport goods, and increase value in other ways through artificial intelligence.

(4) Price and cost risk

This risk involves unexpectedly high prices for suppliers or services. In some cases, business leaders do not provide adequate budgets for the goods and services they expect to receive from suppliers; in other cases, suppliers take advantage of the lack of contracts or "non-fixed" prices to drive up costs and remove costs from business Earn more revenue from your customers. This is one of the easiest risks to avoid, as business leaders can and should conduct due diligence to understand fair prices from suppliers in their market.

Artificial intelligence technology can also help in this regard. Machine learning tools make it easier to conduct cost-benefit analysis to identify opportunities and risks.

(5) Quality Risk

Although cutting corners can reduce costs, doing so can also result in products or services of poor quality that are unattractive to consumers. When considering which suppliers to work with, businesses need to find a balance between affordability and quality.

Some suppliers maintain a consistent level of high or low quality, but for others, quality rises and falls over time. Some factors that may affect quality include material and labor costs in the supplier's region, shipping time and costs, and the complexity of the product or service required. Business leaders who recognize declining quality may try to resolve the issue with their current supplier before seeking a new supplier relationship.

Fortunately, artificial intelligence can help identify these problems.

The best risk mitigation strategies require artificial intelligence technology

Artificial intelligence technology makes it easier for suppliers to manage their risks. Without a doubt, the best way to mitigate supplier-related risks is to use a strong supplier risk management system. The right AI tools and programs can help business leaders conduct more granular research and more accurately evaluate supplier options to develop a supply chain that is less likely to suffer from delays, failures, low quality, undue costs, and other threats. Risk management software developed for supply chain can help business leaders build and maintain strong relationships with top suppliers, which will lead to stable and profitable results for the supply chain of the future.

The above is the detailed content of Artificial Intelligence can help mitigate the top five risks suppliers face. For more information, please follow other related articles on the PHP Chinese website!

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AM

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AMThis article explores the growing concern of "AI agency decay"—the gradual decline in our ability to think and decide independently. This is especially crucial for business leaders navigating the increasingly automated world while retainin

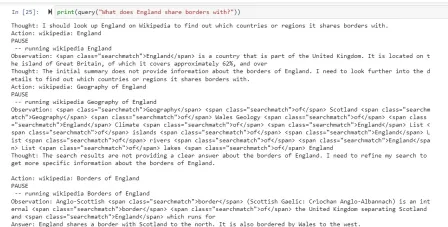

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AM

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AMEver wondered how AI agents like Siri and Alexa work? These intelligent systems are becoming more important in our daily lives. This article introduces the ReAct pattern, a method that enhances AI agents by combining reasoning an

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM"I think AI tools are changing the learning opportunities for college students. We believe in developing students in core courses, but more and more people also want to get a perspective of computational and statistical thinking," said University of Chicago President Paul Alivisatos in an interview with Deloitte Nitin Mittal at the Davos Forum in January. He believes that people will have to become creators and co-creators of AI, which means that learning and other aspects need to adapt to some major changes. Digital intelligence and critical thinking Professor Alexa Joubin of George Washington University described artificial intelligence as a “heuristic tool” in the humanities and explores how it changes

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AM

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AMLangChain is a powerful toolkit for building sophisticated AI applications. Its agent architecture is particularly noteworthy, allowing developers to create intelligent systems capable of independent reasoning, decision-making, and action. This expl

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AM

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AMRadial Basis Function Neural Networks (RBFNNs): A Comprehensive Guide Radial Basis Function Neural Networks (RBFNNs) are a powerful type of neural network architecture that leverages radial basis functions for activation. Their unique structure make

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AM

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AMBrain-computer interfaces (BCIs) directly link the brain to external devices, translating brain impulses into actions without physical movement. This technology utilizes implanted sensors to capture brain signals, converting them into digital comman

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AM

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AMThis "Leading with Data" episode features Ines Montani, co-founder and CEO of Explosion AI, and co-developer of spaCy and Prodigy. Ines offers expert insights into the evolution of these tools, Explosion's unique business model, and the tr

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AM

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AMThis article explores Retrieval Augmented Generation (RAG) systems and how AI agents can enhance their capabilities. Traditional RAG systems, while useful for leveraging custom enterprise data, suffer from limitations such as a lack of real-time dat

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

Dreamweaver Mac version

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool

WebStorm Mac version

Useful JavaScript development tools