Technology peripherals

Technology peripherals AI

AI The profound impact of collaborative robots on the future of manufacturing

The profound impact of collaborative robots on the future of manufacturingThe profound impact of collaborative robots on the future of manufacturing

In recent years, collaborative robots have become a common term in cyberspace. Although reliability and efficiency have come under intense scrutiny, human labor has been the traditional way to get things done in industry.

In this regard, robots have been introduced into work-intensive manufacturing sectors to increase productivity and reliability. The robots were introduced under strict supervision because developers believed they lacked human intelligence. This can lead to unpredictable consequences such as accidents and damage to property and cargo.

The shortcomings of traditional robots have prompted the need to introduce collaborative robots with minimal spatial and environmental risks, making them ideal for working alongside humans. Collaborative robots have more human-like interactions and can be easily programmed. This allows them to work in the same workplace as humans without fear of physical danger.

Characteristics of collaborative robots

(1)Collaboration

The main goal of collaborative robots is to help workers achieve their production goals. They help humans rather than replace their jobs. Unlike industrial robots that worked independently in the past, collaborative robots assist humans in their work. They are mainly deployed in areas deemed too onerous or dangerous for workers. These ensure workplace safety and efficiency.

(2)Lightweight and versatile

Collaborative robots are portable due to their light weight, so they can be transferred from one site to another. They are mainly designed to be small and compact to help humans operate them easily. Their workflow has a small footprint and can be installed quickly without the need for major adjustments or redesign.

In this case, there is no need to move machines and production lines as cobots are created to easily collaborate with workers. Additionally, there is no need to adjust the factory layout as these robots can be easily moved.

(3) Trainable and intelligent

Universal robots are a more promising version of traditional industrial robots. Equipped with smart technology and sensors, they are equipped with mechanical compliance sensors that stop moving whenever they come into contact with an object or person.

(4)Easy to use

Collaborative robot manufacturers have made simplicity one of their core features. Anyone who can operate a smartphone can use them. Intelligent robots are adaptable and can learn on the job. They use guided technology to provide workspace and safety for their employees. It remembers new actions and can repeat them for faster operation.

Growing Trend

Since their introduction in 2008, these collaborative robot technologies have grown in popularity, especially among manufacturers. Their ability to increase efficiency and increase productivity by simplifying tasks in a basic setup is an essential feature.

The market growth of collaborative robots is staggering. The International Federation of Robotics estimates annual growth of 40% and revenue of $1.94 billion by 2028.

Where will collaborative robots provide the most value?

Collaborative robots are mainly used in environments where humans and robots need to collaborate. In this case, the human acts as a guide to the robot, supervising the process or learning from the robot. The manufacturing industry is a major beneficiary of the introduction of collaborative robots. Some manufacturers are investing in collaborative robots in the expectation of a quick return on investment, but this is not always the case.

It is recommended to carefully evaluate the areas where cobots can have the most significant impact and select only them. Collaborative robots are programmed to take on a variety of factory tasks such as assembly, material manufacturing, packaging, machining tasks, and assembly. This allows workers to focus on tasks that require the cognitive capabilities of the cobot to perform.

Developers of collaborative robots have conducted extensive research to determine how robots can mimic human decisions and movements. The artificial intelligence associated with these robots has found brilliant solutions that humans cannot hack. The integration of collaborative robots and 5G systems brings better service quality, such as smart manufacturing. In order for the system to be controlled and react quickly, reliable communication is required. This is especially true in collaborative robot production facilities that don’t require much human help.

Impact of Collaborative Robot Deployment

Once a technology is proven trustworthy, it will be widely adopted. In the short time they have been running, collaborative robots have been of great help to the development of modern industry, being able to make many decisions simultaneously.

They can traverse large knowledge graphs with high processing power and complex software architecture. Their execution has become powerful due to recent technological advances such as parallel processing, linked data, and edge computing.

What’s next for service providers?

(1) Service Providers

Service providers must be prepared to provide differentiated and reliable services. They should also meet all infrastructure predictability and security measures to guarantee quality service.

(2) Technology Supplier

Technology suppliers are responsible for the security of the system and should prioritize compliance with set standards and compliance with regulations to ensure the trustworthiness of the system.

(3) Enterprises

Enterprises should develop use cases and frameworks to ensure that human-machine collaboration produces the desired results as this technology matures. Collaborative robots will be efficient if human and machine output coexist. Businesses must ensure that collaborative robots are integrated with their operating modes to avoid service outages or human-robot conflicts.

Conclusion

In short, as the standard describes, the robot cannot do anything but move around. Collaborative robots are safe in this situation because they have limited forces and cover their joints with protective materials so they do not cause harm to humans.

According to the concept of evolution, it is not the strongest or smartest species that survive, but the species that adapt quickly to change. In the long run, people should adapt to survive. Human-machine collaboration is reaching its peak, and every industry (especially manufacturing) must develop this market.

Increased efficiency, reduced personal risk, operational diversification, and increased efficiency indicate that this technology will increasingly be put into use. Collaborative robots will dominate the next industrial revolution. New training and adaptation to new positions will be inevitable to avoid mass job losses among employees.

The above is the detailed content of The profound impact of collaborative robots on the future of manufacturing. For more information, please follow other related articles on the PHP Chinese website!

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AM

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AMThis article explores the growing concern of "AI agency decay"—the gradual decline in our ability to think and decide independently. This is especially crucial for business leaders navigating the increasingly automated world while retainin

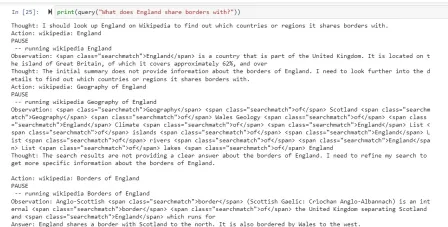

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AM

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AMEver wondered how AI agents like Siri and Alexa work? These intelligent systems are becoming more important in our daily lives. This article introduces the ReAct pattern, a method that enhances AI agents by combining reasoning an

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM"I think AI tools are changing the learning opportunities for college students. We believe in developing students in core courses, but more and more people also want to get a perspective of computational and statistical thinking," said University of Chicago President Paul Alivisatos in an interview with Deloitte Nitin Mittal at the Davos Forum in January. He believes that people will have to become creators and co-creators of AI, which means that learning and other aspects need to adapt to some major changes. Digital intelligence and critical thinking Professor Alexa Joubin of George Washington University described artificial intelligence as a “heuristic tool” in the humanities and explores how it changes

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AM

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AMLangChain is a powerful toolkit for building sophisticated AI applications. Its agent architecture is particularly noteworthy, allowing developers to create intelligent systems capable of independent reasoning, decision-making, and action. This expl

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AM

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AMRadial Basis Function Neural Networks (RBFNNs): A Comprehensive Guide Radial Basis Function Neural Networks (RBFNNs) are a powerful type of neural network architecture that leverages radial basis functions for activation. Their unique structure make

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AM

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AMBrain-computer interfaces (BCIs) directly link the brain to external devices, translating brain impulses into actions without physical movement. This technology utilizes implanted sensors to capture brain signals, converting them into digital comman

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AM

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AMThis "Leading with Data" episode features Ines Montani, co-founder and CEO of Explosion AI, and co-developer of spaCy and Prodigy. Ines offers expert insights into the evolution of these tools, Explosion's unique business model, and the tr

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AM

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AMThis article explores Retrieval Augmented Generation (RAG) systems and how AI agents can enhance their capabilities. Traditional RAG systems, while useful for leveraging custom enterprise data, suffer from limitations such as a lack of real-time dat

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

Dreamweaver Mac version

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool

WebStorm Mac version

Useful JavaScript development tools