In the wake of the COVID-19 pandemic, automation has made a huge splash across the globe, transforming business and having a significant impact on the growth and development cycles of organizations. Automation trends such as intelligent automation, hyperautomation, chatbots, etc. are being widely used by enterprises to process massive amounts of data, automate business operations, and make them faster and more efficient. Changing customer demands are driving businesses to double down on delivery efforts—refocusing on operational efficiency, productivity, and resiliency.

A recent Deloitte report stated that 53% of organizations have begun implementing robotic process automation (RPA). Additionally, Gartner predicts that hyperautomation will reduce organizations’ operating costs by 30% by 2024. By 2025, the market size of hyperautomation software will reach nearly $860 billion.

What businesses need today is agility, but most organizations fail to achieve it due to legacy technology infrastructure. Innovations in automation will enable organizations to reuse their existing infrastructure to adapt to changing customer needs and help them gain customer loyalty in a cost-effective manner.

Here are the top five trends for automation in 2023:

1. Low-code and no-code platforms

Low-code and no-code platforms use visual interfaces to enable users to develop their own Business solutions without extensive coding knowledge. Business users praise low-code platforms because it is easy to adopt and learn to create the desired solution in a matter of days, without having to write code or know a programming language. Platform code automation enables market leaders to introduce low-code and no-code platforms into their product lines as they see huge growth potential for global adoption in 2023 across industries.

2. Collaborative robots and chatbots

are machines that interact side by side with humans in a shared professional environment. These cobots can include heavy machinery in warehouses, robots in assembly lines, and robots used for metal cutting. Collaborative robots are known to quickly adapt to new tasks, learn from repetition and pattern recognition, and optimize workflow. Since cobots exist in shared environments and do not replace human labor, the demand for cobots in the manufacturing industry is rising and will become a trend in the coming years.

3. Security Automation

Data security has always been one of the top priorities for chief information officers in various industries. Security leaders are designing new ways to create robust and resilient frameworks for their organizations. Many information security OEMs have introduced automated security that does not require any human intervention, using artificial intelligence and machine learning to provide continuous monitoring of the data environment. It also uses predefined algorithms to detect and resolve cyber threats. Security meshes have been in constant demand, with organizations and security leaders looking to adopt a network security mesh where different security services can be integrated in a flexible framework.

4. Hybrid work model

Gartner states that by 2024, organizations adopting the above architecture will reduce the financial impact of security incidents by an average of 90%. However, to be successful, they must manage APIs, connections, and automation bots from a single management interface.

Hybrid working models bridge the gap between the technology and devices used in personal and professional environments. People working from home have become accustomed to smart devices and find them useful and efficient in many ways. These smart devices will also find their way into their workplaces as they are able to complete certain tasks efficiently. Organizations are recognizing the potential of smart devices and are working to introduce them into the workplace, creating a collaborative environment between devices and people to achieve greater efficiency. Voice-activated smart devices can be used to manage schedules, set reminders, make calls, and even help with reading.

5. Use Predictive Maintenance (PdM) Technology

The manufacturing industry has been using predictive maintenance (PdM) technology to identify anomalies in processes and machines and proactively fix them. PdM examines current and past data from connected machines and applications to identify changing patterns and propose remedial actions before they get out of control. This technology has become a trend in the IoT space in recent years, with the automation of equipment maintenance reducing the potential cost impact on the organization due to failure or downtime.

According to Gartner, 60% of IoT predictive maintenance solutions will be offered as part of enterprise asset management products by 2026, compared with 15% in 2021.

Conclusion

2023 will be the year of enterprise automation. Talent shortages, soaring talent costs and competition will drive organizations towards automating processes and reducing their reliance on human labor. Automation will also help the talent pool engage in more productive tasks, promoting career and skill growth while reducing burnout due to repetitive and redundant tasks. In 2023 and beyond, we expect organizations around the world will increasingly adopt innovative automation solutions to enhance production, manage supply chains, optimize operations, and deliver rich omnichannel customer experiences.

The above is the detailed content of Automation trends to watch in 2023. For more information, please follow other related articles on the PHP Chinese website!

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AM

Are You At Risk Of AI Agency Decay? Take The Test To Find OutApr 21, 2025 am 11:31 AMThis article explores the growing concern of "AI agency decay"—the gradual decline in our ability to think and decide independently. This is especially crucial for business leaders navigating the increasingly automated world while retainin

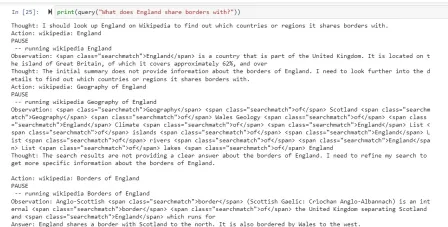

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AM

How to Build an AI Agent from Scratch? - Analytics VidhyaApr 21, 2025 am 11:30 AMEver wondered how AI agents like Siri and Alexa work? These intelligent systems are becoming more important in our daily lives. This article introduces the ReAct pattern, a method that enhances AI agents by combining reasoning an

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM

Revisiting The Humanities In The Age Of AIApr 21, 2025 am 11:28 AM"I think AI tools are changing the learning opportunities for college students. We believe in developing students in core courses, but more and more people also want to get a perspective of computational and statistical thinking," said University of Chicago President Paul Alivisatos in an interview with Deloitte Nitin Mittal at the Davos Forum in January. He believes that people will have to become creators and co-creators of AI, which means that learning and other aspects need to adapt to some major changes. Digital intelligence and critical thinking Professor Alexa Joubin of George Washington University described artificial intelligence as a “heuristic tool” in the humanities and explores how it changes

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AM

Understanding LangChain Agent FrameworkApr 21, 2025 am 11:25 AMLangChain is a powerful toolkit for building sophisticated AI applications. Its agent architecture is particularly noteworthy, allowing developers to create intelligent systems capable of independent reasoning, decision-making, and action. This expl

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AM

What are the Radial Basis Functions Neural Networks?Apr 21, 2025 am 11:13 AMRadial Basis Function Neural Networks (RBFNNs): A Comprehensive Guide Radial Basis Function Neural Networks (RBFNNs) are a powerful type of neural network architecture that leverages radial basis functions for activation. Their unique structure make

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AM

The Meshing Of Minds And Machines Has ArrivedApr 21, 2025 am 11:11 AMBrain-computer interfaces (BCIs) directly link the brain to external devices, translating brain impulses into actions without physical movement. This technology utilizes implanted sensors to capture brain signals, converting them into digital comman

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AM

Insights on spaCy, Prodigy and Generative AI from Ines MontaniApr 21, 2025 am 11:01 AMThis "Leading with Data" episode features Ines Montani, co-founder and CEO of Explosion AI, and co-developer of spaCy and Prodigy. Ines offers expert insights into the evolution of these tools, Explosion's unique business model, and the tr

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AM

A Guide to Building Agentic RAG Systems with LangGraphApr 21, 2025 am 11:00 AMThis article explores Retrieval Augmented Generation (RAG) systems and how AI agents can enhance their capabilities. Traditional RAG systems, while useful for leveraging custom enterprise data, suffer from limitations such as a lack of real-time dat

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment