php Xiaobian Yuzai brings you a detailed description of the elevator RDB-02 motherboard. As the core component of the elevator control system, the RDB-02 mainboard has powerful functions and stability. The motherboard uses advanced technology and can implement a variety of functions, including elevator operation control, fault detection and alarm, etc. At the same time, the RDB-02 motherboard also supports a variety of input and output interfaces to facilitate connection with other devices. Whether in terms of safety or performance, the RDB-02 motherboard is the best choice for your elevator control system. To learn more about the elevator RDB-02 motherboard, please continue reading this article.

Elevator RDB-02 motherboard description?

The elevator RDB-02 motherboard is a core component that controls the operation of the elevator. It is based on embedded system design and has high efficiency and reliability. The motherboard supports the control of multiple types of elevators and can achieve different functions through appropriate installation and program settings.

The mainboard is also equipped with a variety of protection mechanisms, such as overcurrent, overvoltage, low voltage, leakage, etc., to ensure the safety and stability of the elevator during travel. In short, this motherboard is a must-have solution for elevator manufacturers and maintenance service providers, bringing more convenience and security to the elevator industry.

How to check faults on the NCB mainboard of Theo Elevator?

The NCB mainboard of Xio Elevator is the core component of elevator control. When the elevator fails, you need to follow the following steps to troubleshoot: Power supply check: First ensure that the power supply voltage is normal. If the power supply voltage is unstable or too high, Low may cause motherboard failure. Connection check: Check whether the connection between the main board and other parts of the elevator is firm and whether there is any looseness or disconnection. Indicator light check: Observe whether the indicator lights on the motherboard are working normally. If an indicator light does not light up or flashes abnormally, it may indicate that there is a fault in this part. Code viewing: If the elevator has a fault code display, you can troubleshoot according to the code prompts. Replacement troubleshooting: If the cause of the fault cannot be determined through the above steps, you can try to replace the motherboard with another functioning motherboard to determine whether the motherboard is faulty. It should be noted that the above steps require professionals to perform operations, and it is not recommended for non-professionals to conduct troubleshooting on their own. At the same time, before troubleshooting, you need to ensure that the elevator has stopped running and take safety measures to prevent accidents.

What does Kone Elevator need to do to replace the main board?

Replacing the elevator main board is a relatively complicated task. If you are not a professional technician, please do not try to replace it yourself. The following are the general steps:

1. Turn off the elevator power. Before replacing the main board, the elevator power must be turned off and the controller must be discharged. This prevents accidental electric shock and protects equipment during replacement.

2. Remove the old motherboard. The old motherboard needs to be disassembled first, usually using a screwdriver to remove the old motherboard from its mounting points.

3. Record the connection method. Before removing the old motherboard, take note of the location, color, and plug and socket types of all connecting cables and harnesses so that you can connect the correct cables directly when installing the new motherboard.

4. Install the new motherboard. Install the new motherboard according to the instructions provided by the manufacturer or the instructions provided by the technician. This step needs to be performed very carefully to ensure that the new motherboard is installed correctly and securely fastened.

5. Connect the cables and harness. Use the recorded information to connect all cables and harnesses, making sure each plug is plugged into the correct socket.

6. Test the components. Restart the elevator and run through a series of functional tests to check that the newly installed components are working properly. If there is a problem, please shut down immediately and contact professional technicians for repair.

In short, you need to be very careful when replacing the elevator main board, because this is an important task. If done carelessly, it may cause damage to the elevator or serious failure of the elevator. It is recommended to consult with a KONE Elevator professional technician before seeking actual work.

Migao elevator mainboard debugging information?

1. First, check whether the motherboard power supply is normal. Confirm whether the power cord interface is clean and has good contact.

2. After connecting the power supply, press the power switch on the motherboard. At this time, the motherboard will perform a self-test to check whether the various indicators on the motherboard are normal.

3. If the mainboard indicator light is normal, next you need to set the parameters. Enter the mainboard setting interface and make settings according to the specific parameters of the elevator. Note that when setting parameters, you need to set them according to the parameter range provided by the elevator manufacturer, and do not change the parameters at will.

4. After completing the parameter settings, the elevator needs to be debugged. First, perform static debugging to check whether the elevator functions are normal. Then perform dynamic debugging to test the operating effect of the elevator.

5. During debugging, you need to pay attention to safety issues. Keep the elevator operating area safe and avoid accidents. At the same time, pay attention to the data records during the debugging process to facilitate subsequent troubleshooting and maintenance.

Elevator emergency stop and maintenance recovery sequence?

1) Manual method: The elevator stops at the first floor → the elevator enters the machine room for maintenance → keep the door lock closed → manually operate the up button → the car leaves the door area (the X2 light on the control main board input point goes out) and manual operation is performed immediately Emergency stop switch → the elevator stops running → measure the distance between the car door sill and the landing door sill → restore the elevator to normal.

2) Automatic mode: The elevator stops at the first floor - the elevator enters the machine room for maintenance → keep the door lock closed → set F8 to 7 on the mainboard small keyboard (E88 is displayed at this time, turn on the UCMP test function) → Disconnect the door lock circuit → manually operate the up button → the elevator leaves the door area → the elevator stops running and reports E65 (UCMP fault) → measure the distance between the car door sill and the landing door sill → restore the elevator to normal.

How to deal with the mainboard failure 51 reported by Xizi Elevator Umai system?

When the Xizi Elevator Umai system reports a motherboard failure of 51, the elevator should be stopped immediately and the relevant maintenance personnel should be notified for maintenance.

Maintenance personnel should first check the motherboard to see if the circuit on the motherboard is normal and whether there is a short circuit or open circuit. If a fault is found, the motherboard should be replaced or repaired in time. At the same time, maintenance personnel should also check other related components to ensure the normal operation of the elevator. After the repair is completed, comprehensive testing should be conducted to ensure the safety and reliability of the elevator. Finally, elevator users should be informed of the troubleshooting situation in a timely manner to avoid unnecessary panic or misunderstanding.

How to debug the main board of CANNY Elevator?

After replacing the CANNY elevator main board, debugging is required to ensure the normal operation of the elevator. Please note that debugging the elevator mainboard requires professional knowledge and skills. The following is an overview of general CANNY elevator mainboard debugging steps, but the specific steps may vary depending on the elevator model and control system. It is strongly recommended that you seek the support of professional elevator technicians or CANNY Elevator Company for correct debugging.

1. Install the mainboard: Install the new CANNY elevator mainboard into the elevator control box, making sure it is properly connected to other components of the elevator system. Follow the installation instructions provided by CANNY Elevator Company.

2. Connect cables: Connect all necessary cables, including power cables, communication cables, motor cables, sensor cables, etc. Make sure the cable is plugged in correctly and the connection is secure.

3. Check the power supply: Make sure the mainboard is connected to a reliable power supply, and check whether the power supply voltage meets the requirements of the CANNY elevator mainboard. Make sure the power supply is stable and there are no electrical issues.

4. Program setting: Set and adjust the parameters on the mainboard according to the requirements of the CANNY elevator mainboard. These parameters may include floor settings, operating speed, fault alarm settings, elevator door control, etc. Use the debugging tools or software provided by CANNY Elevator Company to set up.

5. Operation test: Carry out operation test to ensure the normal operation of the elevator. Test various functions of the elevator, including opening the door, closing the door, going up, going down, floor display, etc. Observe and record the operation of the elevator to ensure that all operations are normal and error-free.

6. Troubleshooting: If you encounter any problems or abnormalities during debugging, use troubleshooting methods to diagnose. Refer to the troubleshooting guide provided by CANNY Elevator Company and take appropriate repair measures according to the situation.

Please note that the above steps only provide a general overview and do not cover all possible scenarios. CANNY Elevator mainboard debugging requires professional technical knowledge and experience. If you have no relevant experience, it is strongly recommended that you seek support from professional elevator technicians or CANNY Elevator Company to ensure correct mainboard debugging and safe operation of the elevator.

How to check the fault on the main board of the elevator control cabinet?

The specific methods are as follows: 1. Problems and faults in the elevator can be diagnosed by searching for fault codes on the main board.

2. The elevator main board will record the fault codes during the operation of the elevator. The problem can be determined based on different codes.

At the same time, repair and maintenance can be carried out according to the instructions in the fault code manual.

3. When using Lingjie elevator, if you encounter a problem and need to find a fault code, you can follow the following steps: a. First find the location of the main board. There is a small screen next to the main board; b. Press Hold the setting button on the screen and press down 5 times at the same time to enter the menu; c. Select "Fault Code" to enter the fault code page; d. According to the fault code displayed on the page, check the fault code manual and follow the instructions in the manual. Processed using the method described above.

How to change the maintenance speed of the Newstar elevator mainboard?

To change the maintenance speed of the Newstar elevator mainboard, you first need to enter the control system of the elevator mainboard and find the setting options related to the maintenance speed. Then adjust the maintenance speed parameter value according to the user manual or relevant technical specifications.

After completing the parameter adjustment, it is necessary to retest the elevator's maintenance speed to ensure that it meets the safe and reliable operation requirements. It should be noted that modifying the maintenance speed of the elevator main board is an elevator maintenance job and needs to be performed by qualified elevator maintenance personnel to ensure the normal operation of the elevator and the safety of passengers.

The above is the detailed content of RDB-02 Elevator Main Board Instructions. For more information, please follow other related articles on the PHP Chinese website!

What if KB5055683 Fails to Install? Here Are Some FixesApr 21, 2025 pm 08:03 PM

What if KB5055683 Fails to Install? Here Are Some FixesApr 21, 2025 pm 08:03 PMThe KB5055683 cumulative update is designed to improve the quality and reliability of .NET Framework 3.5, 4.8 and 4.8.1 in Windows 10 systems. If you encounter the failure of KB5055683 installation, how to solve it? This article will provide effective solutions. Windows 10 KB5055683 Update KB5055683 is a cumulative update for .NET Framework 3.5, 4.8 and 4.8.1 for Windows 10 22H2 versions, released on April 8, 2025. This update contains all security improvements from previous versions, but no new security improvements were added. It is recommended that you download and install KB50 as soon as possible

Fresh Guide! Fix REMATCH A D3D12-compatible GPU ErrorApr 21, 2025 pm 08:01 PM

Fresh Guide! Fix REMATCH A D3D12-compatible GPU ErrorApr 21, 2025 pm 08:01 PMEncountering the REMATCH D3D12-compatible GPU error on Windows? This guide provides solutions to get you back in the game. REMATCH, a multiplayer online football game, requires a graphics card supporting DirectX 12 (Feature Level 12.0, Shader Model

Clone a Hard Drive Without OS, Watch Pro Guide with Easy StepsApr 21, 2025 am 10:24 AM

Clone a Hard Drive Without OS, Watch Pro Guide with Easy StepsApr 21, 2025 am 10:24 AMThis guide shows you how to clone a hard drive even if your Windows system won't boot. MiniTool ShadowMaker simplifies this process. Windows boot failures are common, caused by issues like corrupted system files or MBR errors. Cloning your hard dri

League of Legends Play Button Not Working on PC: ResolvedApr 21, 2025 am 10:09 AM

League of Legends Play Button Not Working on PC: ResolvedApr 21, 2025 am 10:09 AMThe League of Legends game buttons do not work properly, resulting in the inability to enter the game? don’t worry! This guide will guide you to solve this problem quickly and effectively, allowing you to easily resume the game. Just follow the steps below to quickly resolve the game button issue! Quick navigation: League of Legends game buttons don't work How to fix League of Legends game buttons not working on PC Summarize League of Legends game buttons don't work As a MOBA game, League of Legends continues to attract global players and has a huge and stable player group. To enhance the gaming experience, Riot Games regularly releases updates to introduce new content, but this doesn't always go smoothly. Sometimes, some accidental technical failures may occur after a new update, such as League of Legends games

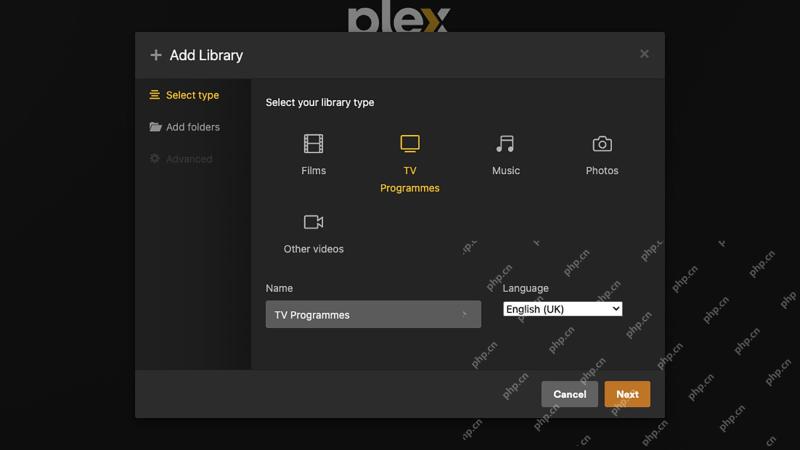

How to use Plex to create your own private Netflix or SpotifyApr 20, 2025 am 10:13 AM

How to use Plex to create your own private Netflix or SpotifyApr 20, 2025 am 10:13 AMBuild Your Own Streaming Service with Plex: A Step-by-Step Guide We're accustomed to on-demand content at our fingertips, thanks to services like Netflix and Spotify. However, building a personal media library offers unique advantages: ownership and

Spotlight on How to Fix Taskbar Search Bar Blank Box on WindowsApr 19, 2025 pm 08:06 PM

Spotlight on How to Fix Taskbar Search Bar Blank Box on WindowsApr 19, 2025 pm 08:06 PMTroubleshooting a Blank Windows 11/10 Taskbar Search Box A blank search bar in Windows 10 or 11 severely impacts usability. This guide offers solutions to resolve this common issue, preventing you from easily searching for apps and files. The Proble

How to Fix Forever Skies Crashing? Try the 6 Effortless WaysApr 19, 2025 pm 08:01 PM

How to Fix Forever Skies Crashing? Try the 6 Effortless WaysApr 19, 2025 pm 08:01 PMEncountering crashes in Forever Skies? This guide offers solutions to get your game running smoothly. We'll cover troubleshooting steps for crashes on startup and provide fixes for common causes. Forever Skies Crashes at Startup: Common Causes Fore

Device Manager Is Blank or Not Showing Anything? Fix It NowApr 19, 2025 pm 06:02 PM

Device Manager Is Blank or Not Showing Anything? Fix It NowApr 19, 2025 pm 06:02 PMTroubleshooting a Blank Device Manager in Windows Device Manager, a crucial Windows utility for managing hardware, can sometimes fail to display any content. This issue, often caused by disabled services or registry permission problems, can lead to v

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

VSCode Windows 64-bit Download

A free and powerful IDE editor launched by Microsoft

SublimeText3 Mac version

God-level code editing software (SublimeText3)

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.

Dreamweaver Mac version

Visual web development tools