Vision application technology in medical manufacturing

There is a small but extremely important ingredient in modern medicine. It enters arteries during procedures such as angiography, or plays a central role in life-saving organ surgeries.

It will make your hair stand on end just thinking about its importance. The precision and quality of these small parts are critical to patients.

As medical science advances and disease complexity continues to increase, so does the need for tiny yet critical medical components. These components play the role of unsung heroes in the operating room and are the silent defenders of our health. However, producing these components is no easy task. Factories need to produce these components in large quantities, not only to ensure the highest quality standards, but also to do so quickly, leaving no room for error.

So, how should we respond? Enter the cutting-edge world of visual technology and the transformative power of Industry 4.0. In this article, we explore how the integration of robotics and vision systems is transforming medical manufacturing, ushering in a new era of precision and safety.

Vision Check

Vision has become a key tool to ensure the quality of manufacturing products. Over the past decade, computer-aided vision systems have gradually replaced humans in quality inspection, marking a major advance in the field. Innovations and improvements in vision technology are opening up new ways to inspect complex parts, significantly reducing human error.

Current visual inspection capabilities in medical manufacturing have been expanded to include inspection of 2D and 3D dimensions using predefined scales. The strength of this technology plays a key role in maintaining high standards of medical devices and equipment and has a positive impact on cost savings in medical manufacturing as well as four other major industries. It is estimated that this technology could save these five major industries approximately $200 million per year.

The company can provide computer-aided vision integrated solutions for the medical manufacturing field to ensure high precision, high efficiency and compliance with strict quality standards. As the medical manufacturing industry develops, the demand for advanced visual inspection technology will continue to increase, further improving the overall quality and reliability of medical products.

Quality Metrics and SPC

The use of advanced vision machines in manufacturing produces two different types of data as output. The first is quality indicator data, which represents analog and individual measurement data in numerical form. In medical manufacturing, accuracy is critical and these metrics are key metrics. They are subject to predefined limitations that determine each part's eligibility for use in a real-time medical environment. This data can be used to evaluate product quality and can be used to monitor and improve manufacturing processes. By using advanced vision machines, manufacturers can more accurately detect and measure key features of their products, ensuring they meet required quality standards. This data can also be used to predict and prevent potential quality issues, thereby reducing the number of substandard products and improving overall manufacturing efficiency. Therefore, the application of advanced vision machines in medical manufacturing is crucial to ensuring product quality and improving production efficiency. Industry 4.0 applications are designed for complex medical manufacturing and can seamlessly integrate advanced machines. Through standard protocols, applications are able to obtain quality metric data and compare it to predefined specifications. Real-time analysis quickly draws conclusions about the quality of each part. The collected data can be stored and visually displayed in the form of charts, which facilitates in-depth data analysis for continuous improvement.

Furthermore, these advanced machines are capable of providing decisive data such as acceptance or rejection based on predefined settings. Not only is this information valuable for immediate decision-making, but it also helps sort parts into their respective bins.

It turns out that the granularity of the metric data combined with specific decisions helps further classify parts. This, in turn, helps make informed decisions about rework and rejection, ensuring that only components that meet the highest quality standards make it through the manufacturing process.

Visual Technology, Robotics and Classification

With the advent of the Internet of Things and connected machines, we can go a step further and completely eliminate human error from the system. Robots on production lines can perform monotonous and scheduled tasks, placing medical parts on vision tables and placing them back into bins. Sustainability plays a key role in medical manufacturing, not just from an environmental or waste perspective, but also from a profit and revenue perspective.

Every factory, including medical factories, should and will have two levels - reject and scrap. Sending everything directly to scrap increases the cost of raw materials and therefore the overall cost. Rejections can be divided into groups based on the problem they cause or the type of rework required. Separating parts into scrap and scrap based on data should use Industry 4.0 and data analytics applications along with the data and signals received from the vision system.

The significance of Industry 4.0 applications

The digital transformation of factories is an important part of Industry 4.0 applications. It involves integrating critical information, including process, product, machine and quality metrics, into a unified platform customized for the unique needs of medical manufacturing.

The strength of this application is its ability to perform correlation analysis on medical components, gaining insights from comprehensive data that spans multiple operations and includes raw material information. This depth and breadth of data enables applications to make informed decisions about accepting or rejecting medical parts. In areas where accuracy and quality cannot be compromised, this analytical capability proves invaluable.

The artificial intelligence (AI) and machine learning (ML) components integrated into the application further enhance its capabilities. These advanced technologies can generate alerts in real time, providing immediate feedback on previous production processes.

In cases where scrap rates exceed acceptable thresholds, the system can take decisive action, including stopping the production process to prevent the spread of substandard parts. This proactive approach maintains the highest levels of quality and compliance with medical manufacturing industry standards, ensuring production standards are not compromised and emphasizing the role of applications in the process.

Impact on Medical Manufacturing and ROI

The impact of implementing advanced technologies in medical manufacturing is revolutionary and can significantly increase overall productivity. Against this backdrop, productivity in the industry is expected to increase by at least 50%, marking a significant leap. Of particular note is the elimination of errors and the need for re-inspections during quality control, helping to achieve a more streamlined and efficient production workflow.

Return on investment (ROI) is accelerated due to immediate productivity gains. As these technologies are implemented, the payback period can range from 3 to 6 months, depending on the complexity of the specific medical manufacturing process and product involved. This rapid return on investment highlights the tangible benefits and cost-effectiveness of integrating advanced technologies into medical manufacturing.

This comprehensive improvement in productivity and quality is particularly suitable for workshops engaged in large-scale testing of similar medical components. Streamlined processes and increased efficiencies facilitate the seamless integration of these technologies, resulting in significant positive impacts on the overall manufacturing landscape.

For smaller batches in medical manufacturing, quality will still improve, although configuration and setup costs may vary based on the unique characteristics of the product being inspected. Despite potential cost changes, the overall impact on quality remains a significant advantage, demonstrating the adaptability of these technologies in medical manufacturing operations of varying sizes.

Conclusion

In short, the integration of visual technology and Industry 4.0 is not just a technological evolution; This is a revolution in precision and reliability in medical manufacturing. As we continue down this path, we expect not only further advances in technology, but also profound impacts on patient outcomes and the overall healthcare landscape. The journey toward precision in medical manufacturing continues, and through the lens of vision technology and Industry 4.0, the future promises unparalleled advancements and life-changing innovations.

The above is the detailed content of Vision application technology in medical manufacturing. For more information, please follow other related articles on the PHP Chinese website!

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AM

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AMRunning large language models at home with ease: LM Studio User Guide In recent years, advances in software and hardware have made it possible to run large language models (LLMs) on personal computers. LM Studio is an excellent tool to make this process easy and convenient. This article will dive into how to run LLM locally using LM Studio, covering key steps, potential challenges, and the benefits of having LLM locally. Whether you are a tech enthusiast or are curious about the latest AI technologies, this guide will provide valuable insights and practical tips. Let's get started! Overview Understand the basic requirements for running LLM locally. Set up LM Studi on your computer

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AM

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AMGuy Peri is McCormick’s Chief Information and Digital Officer. Though only seven months into his role, Peri is rapidly advancing a comprehensive transformation of the company’s digital capabilities. His career-long focus on data and analytics informs

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AM

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AMIntroduction Artificial intelligence (AI) is evolving to understand not just words, but also emotions, responding with a human touch. This sophisticated interaction is crucial in the rapidly advancing field of AI and natural language processing. Th

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AM

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AMIntroduction In today's data-centric world, leveraging advanced AI technologies is crucial for businesses seeking a competitive edge and enhanced efficiency. A range of powerful tools empowers data scientists, analysts, and developers to build, depl

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AM

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AMThis week's AI landscape exploded with groundbreaking releases from industry giants like OpenAI, Mistral AI, NVIDIA, DeepSeek, and Hugging Face. These new models promise increased power, affordability, and accessibility, fueled by advancements in tr

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AM

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AMBut the company’s Android app, which offers not only search capabilities but also acts as an AI assistant, is riddled with a host of security issues that could expose its users to data theft, account takeovers and impersonation attacks from malicious

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AM

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AMYou can look at what’s happening in conferences and at trade shows. You can ask engineers what they’re doing, or consult with a CEO. Everywhere you look, things are changing at breakneck speed. Engineers, and Non-Engineers What’s the difference be

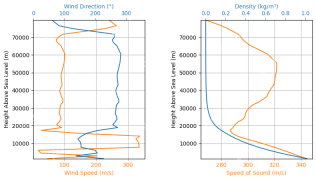

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AM

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AMSimulate Rocket Launches with RocketPy: A Comprehensive Guide This article guides you through simulating high-power rocket launches using RocketPy, a powerful Python library. We'll cover everything from defining rocket components to analyzing simula

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

VSCode Windows 64-bit Download

A free and powerful IDE editor launched by Microsoft

SublimeText3 Linux new version

SublimeText3 Linux latest version

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.

Dreamweaver CS6

Visual web development tools