Technology peripherals

Technology peripherals AI

AI Only Tesla and Changan Qiyuan digital AI electric drives can achieve the feat of 10-layer windings? Interpretation of Changan Qiyuan digital AI electric drive (Part 2)

Only Tesla and Changan Qiyuan digital AI electric drives can achieve the feat of 10-layer windings? Interpretation of Changan Qiyuan digital AI electric drive (Part 2)Only Tesla and Changan Qiyuan digital AI electric drives can achieve the feat of 10-layer windings? Interpretation of Changan Qiyuan digital AI electric drive (Part 2)

We have discussed in the last issue why the engine of Changan Qiyuan Digital AI Electric Drive (Part 1) is so fuel-efficient, achieving a comprehensive fuel consumption of 0.98L per 100 kilometers. In this issue, let’s explore how its electric motor achieves such power saving and efficiency

Only Changan and Tesla use 10-layer winding

One of the biggest highlights of Changan Qiyuan Digital Intelligence AI electric drive is the application of 10-layer motor windings. Before this, only Tesla had used 10-layers, and 10-layer motors are already top-notch, because This is crucial for the motor to achieve higher power and higher efficiency.

There is a phenomenon in electromagnetism called the skin effect. When alternating current or alternating electromagnetic field exists in a conductor, the current distribution inside the conductor is uneven. The current is mainly concentrated in the surface layer of the conductor, the so-called "skin" layer. The closer to the surface of the conductor, the greater the current density, while the current inside the conductor is smaller. This is the so-called skin effect

That is to say, the copper wire contributes more to the outer surface than the inside. The more the better, 1 copper wire has 1 outer surface circle, and 10 copper wires equal 10 circles. The so-called number of layers (number of copper wires) of a flat wire motor is the number of flat copper wires placed in the stator slot. As the number of motor layers increases, the slot fill rate is higher, and the material utilization rate increases, ultimately achieving higher power and efficiency.

According to official data, Changan Qiyuan’s digital AI electric drive motor has a peak electric drive power of 158kW (BYD Qin PLUS is 145kW), a power density of 7kW/kg, a maximum efficiency of 97.8%, and more than 90% The efficiency exceeds 90%.

As for how difficult such a design is, we will not discuss it here for the time being. Even if it is 12 layers, it is possible and can be demonstrated in the laboratory. However, mass production must take into account more practical issues. First One is that the cost is too high.

Nowadays, many other competing products are still using 6 layers, and a few are 8 layers. For example, the famous BYD DM-i hybrid uses 6 layers.

Tesla and Changan Qiyuan are the only car companies in the world that use 10-layer Hairpin flat wire oil-cooled motor winding technology in mass production. Changan Qiyuan's P1 generator motor has 8 layers, and the P3 drive motor has 10 layers. It needs to be reminded that Tesla is a pure electric vehicle, while Changan Qiyuan is a plug-in hybrid model, which shows how much Changan attaches importance to the electric part

In a hybrid drive, the motor is the main power source and is responsible for tasks such as fast torque response, energy recovery, and operating point adjustment. Therefore, a large amount of money is spent on electric drives. Considering the difficulty and cost of design and manufacturing, Changan Qiyuan's 10-layer Hairpin flat wire motor may stay ahead in 3-5 years.

0.27mm silicon steel sheet “way ahead”

Observe the 10 layers of copper wires on the stator of the P3 motor, and then talk about the silicon steel sheets on the rotor. Since the design speed of the stator is as high as 13,000 rpm, the quality standards for the silicon steel sheets are very high

Competing brands should have a thickness of about 0.3mm. The silicon steel sheet should be thin and the problem of curling should be overcome. The drive motor of Changan Qiyuan uses silicon steel sheets with a thickness of 0.27mm, which is the thinnest silicon steel sheet specification in mass production. For the same motor stack height, the thinner the thickness of the silicon steel sheet, the smaller the eddy current loss, which is often said to be lower iron loss. The 0.27mm silicon steel sheet motor is 0.3% more efficient than competing 0.3mm silicon steel sheet motors.

Reduce the speed and increase the counter pole to achieve lightweight

This set of electric drives highly integrates the P1 motor and clutch, and the clutch is built into the P1 motor. Through this innovative method, the transmission system can be made into 3 axes and 6 teeth, while the competitive product has 4 axes and 8 teeth, which reduces By replacing one shaft with two teeth, the volume becomes smaller, the weight is lighter, and the efficiency can be increased by 1%.

Official data: This set of Changan Qiyuan digital AI electric drive weighs only 110kg, which is about 30kg lighter than competing products; its volume is 26% smaller and its height is 81mm lower.

The advantage of the lightweight electric drive system is that the vehicle design is more possible, which can achieve a lower and sportier appearance, and can save front cabin space, thereby providing a more spacious passenger cabin space

Changan Qiyuan miniaturizes the P1 motor and directly connects it to the engine output shaft to achieve coaxial output. This saves one shaft and two gears, and does not require speed increase, thus realizing the connection with the engine. The perfect combination of efficient areas

But in order to burst out large torque at a lower speed, it is necessary to achieve the goal by using more poles. Because the higher the motor speed, the greater the power it generates, but the design speed of Changan Qiyuan's P1 motor is not very high, it is 6500rpm.

The more poles the motor has, the larger the effective volume of the motor is, which can make up for the lack of power density. The so-called opposing poles (magnetic poles) are the N pole and S pole that exist in pairs. One N pole and one S pole form an opposing pole.

The P1 motor of Changan Shuzhi AI electric drive uses 8-layer windings and has 12 pairs of poles (competing products have 4 pairs of poles). This allows the motor to obtain a large current at a low speed of 6500rpm, while competing products require 19500rpm

to achieve the same effect.

Its P1 motor is designed with 12 pairs of magnetic poles, and the P3 motor also has 6 pairs of magnetic poles. Since the number of motor pole pairs is greater than that of competing products, the power density of P1 and P3 motors has increased. The power density of P3 motor has reached 7kW/kg. For high-speed motors such as BYD DM-i hybrid, this data is only to 6kW/kg.

Quad-core chip algorithm achieves fuel saving

In terms of fuel saving, "extreme footwork" may have achieved good results in the past, but in the era of electrification, the role of chip computing power has been greatly enhanced, and it can help you make the most fuel-saving plan in real time.

The controller of Changan Qiyuan's electric drive is a quad-core TC387 chip with 300 megabits of computing power per core as the main MCU chip. Its computing power is 50 times higher than that of the two single-core chips of competing products. %.

The control system will input all parameters of the motor, battery, engine, transmission system, etc. into the PCU, and collect more than 500 types of information on the driver, vehicle, etc. at all times, and continue to dynamically optimize. In the actual use scenario of the user, it can save 6% of energy. .

For example, by using navigation information, the entire trip can be planned, energy can be reasonably allocated, fuel will be used when it is smooth, and electricity will be used when there is congestion. On mountain roads like Chongqing, you can reduce the difference by pressing the accelerator, just like driving on flat ground

The content that needs to be rewritten is: Summary

After analysis, the core of Changan Qiyuan's digital AI electric drive is electricity. The electric drive is the main force, and the engine is responsible for coordination, so the motor part is more important than before.

Through the stacking of technologies such as 10-layer flat wire motor windings, the thinnest 0.27mm silicon steel sheet in mass production, redesigned highly integrated generators and 12 pairs of magnetic poles, we achieve greater fuel and power savings. The engine focuses on high efficiency and gives more drive to the motor. The maximum power of the drive motor is 158kW, which can basically drive a medium-sized SUV easily.

The power of the engine is not excessive, but the power of the drive motor is very high. This design makes the vehicle both fuel-efficient and powerful. It is a bit like letting a cow eat less grass but work more. This is the best combination. . In addition, this electric drive system does not result in excessive costs, which also makes the entire vehicle more affordable. Now, you can choose electric drive with confidence and at a very reasonable price. Can Changan Qiyuan become your first choice when buying a car?

The above is the detailed content of Only Tesla and Changan Qiyuan digital AI electric drives can achieve the feat of 10-layer windings? Interpretation of Changan Qiyuan digital AI electric drive (Part 2). For more information, please follow other related articles on the PHP Chinese website!

Tesla's Robovan Was The Hidden Gem In 2024's Robotaxi TeaserApr 22, 2025 am 11:48 AM

Tesla's Robovan Was The Hidden Gem In 2024's Robotaxi TeaserApr 22, 2025 am 11:48 AMSince 2008, I've championed the shared-ride van—initially dubbed the "robotjitney," later the "vansit"—as the future of urban transportation. I foresee these vehicles as the 21st century's next-generation transit solution, surpas

Sam's Club Bets On AI To Eliminate Receipt Checks And Enhance RetailApr 22, 2025 am 11:29 AM

Sam's Club Bets On AI To Eliminate Receipt Checks And Enhance RetailApr 22, 2025 am 11:29 AMRevolutionizing the Checkout Experience Sam's Club's innovative "Just Go" system builds on its existing AI-powered "Scan & Go" technology, allowing members to scan purchases via the Sam's Club app during their shopping trip.

Nvidia's AI Omniverse Expands At GTC 2025Apr 22, 2025 am 11:28 AM

Nvidia's AI Omniverse Expands At GTC 2025Apr 22, 2025 am 11:28 AMNvidia's Enhanced Predictability and New Product Lineup at GTC 2025 Nvidia, a key player in AI infrastructure, is focusing on increased predictability for its clients. This involves consistent product delivery, meeting performance expectations, and

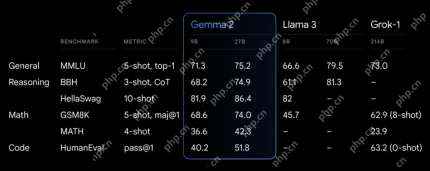

Exploring the Capabilities of Google's Gemma 2 ModelsApr 22, 2025 am 11:26 AM

Exploring the Capabilities of Google's Gemma 2 ModelsApr 22, 2025 am 11:26 AMGoogle's Gemma 2: A Powerful, Efficient Language Model Google's Gemma family of language models, celebrated for efficiency and performance, has expanded with the arrival of Gemma 2. This latest release comprises two models: a 27-billion parameter ver

The Next Wave of GenAI: Perspectives with Dr. Kirk Borne - Analytics VidhyaApr 22, 2025 am 11:21 AM

The Next Wave of GenAI: Perspectives with Dr. Kirk Borne - Analytics VidhyaApr 22, 2025 am 11:21 AMThis Leading with Data episode features Dr. Kirk Borne, a leading data scientist, astrophysicist, and TEDx speaker. A renowned expert in big data, AI, and machine learning, Dr. Borne offers invaluable insights into the current state and future traje

AI For Runners And Athletes: We're Making Excellent ProgressApr 22, 2025 am 11:12 AM

AI For Runners And Athletes: We're Making Excellent ProgressApr 22, 2025 am 11:12 AMThere were some very insightful perspectives in this speech—background information about engineering that showed us why artificial intelligence is so good at supporting people’s physical exercise. I will outline a core idea from each contributor’s perspective to demonstrate three design aspects that are an important part of our exploration of the application of artificial intelligence in sports. Edge devices and raw personal data This idea about artificial intelligence actually contains two components—one related to where we place large language models and the other is related to the differences between our human language and the language that our vital signs “express” when measured in real time. Alexander Amini knows a lot about running and tennis, but he still

Jamie Engstrom On Technology, Talent And Transformation At CaterpillarApr 22, 2025 am 11:10 AM

Jamie Engstrom On Technology, Talent And Transformation At CaterpillarApr 22, 2025 am 11:10 AMCaterpillar's Chief Information Officer and Senior Vice President of IT, Jamie Engstrom, leads a global team of over 2,200 IT professionals across 28 countries. With 26 years at Caterpillar, including four and a half years in her current role, Engst

New Google Photos Update Makes Any Photo Pop With Ultra HDR QualityApr 22, 2025 am 11:09 AM

New Google Photos Update Makes Any Photo Pop With Ultra HDR QualityApr 22, 2025 am 11:09 AMGoogle Photos' New Ultra HDR Tool: A Quick Guide Enhance your photos with Google Photos' new Ultra HDR tool, transforming standard images into vibrant, high-dynamic-range masterpieces. Ideal for social media, this tool boosts the impact of any photo,

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Atom editor mac version download

The most popular open source editor

SublimeText3 Linux new version

SublimeText3 Linux latest version

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

Zend Studio 13.0.1

Powerful PHP integrated development environment

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.