Technology peripherals

Technology peripherals AI

AI State-owned enterprises use artificial intelligence technology to realize intelligent improvements in sand and gravel aggregate production

State-owned enterprises use artificial intelligence technology to realize intelligent improvements in sand and gravel aggregate productionState-owned enterprises use artificial intelligence technology to realize intelligent improvements in sand and gravel aggregate production

On November 16, news came from the China Building Materials Circulation Association. The scientific and technological achievements of the "High-speed Railway Mechanism Aggregate Production and Application Integrated Intelligent Monitoring Platform Research and Development and Engineering Application" participated by the China Railway Fourth Bureau Materials Company won the First prize in the science and technology progress category of the Science and Technology Award selected by the association.

This award is approved by the Ministry of Science and Technology and is a nationwide industry science and technology award initiated and specifically organized by the China Building Materials Circulation Association in the award series of the National Science and Technology Award Office. It is reviewed and awarded once a year.

The above-mentioned scientific and technological achievements are inseparable from the efforts of a young scientific and technological innovation team. The company team aims at the pain points and difficulties in the mining and processing of sand and gravel aggregates in construction, which are affected by uneven resource distribution, unstable quality of finished products, heavy mining environmental pollution, and many factors affecting transportation distance. Introduces artificial intelligence, big data and other AI technologies to improve sand processing The entire process of stone aggregate processing and transportation is automatically monitored and analyzed, making it possible to implement high-quality and large-scale sand and gravel aggregate production and processing.

Since 2019, China Railway Fourth Bureau Materials Company has set the goal of “environmental protection priority, superior quality, wisdom leadership, and innovation drive”. It has successively completed Changjinghuang, Yuxiang, and Xunda in key railway construction projects. , Tongka, Matama and other 6 green sand and gravel processing plants. The processing plant processes previous tunnel ballast waste into high-quality sand and gravel aggregate for project construction, reducing resource waste and achieving the unification of economic, environmental and social benefits. The comprehensive utilization rate of raw materials has increased to 97%, reaching the national green mine standard. The innovative achievements in comprehensive processing and utilization of ballast also won the second prize of "National Management Innovation".

In addition, during the production and construction of sand and gravel processing plants, the company focused on building an intelligent monitoring platform to improve the quality of processed products, and gradually realized the intelligent iteration of the monitoring platform. In 2023, the company cooperated with China Academy of Railway Sciences and other enterprises to develop online monitoring of gravel-machine-made sand-stone powder production quality, environmental monitoring and pollution prevention of machine-made aggregate processing plants, and machine-made aggregate logistics tracking and control based on the Internet of Things. Five major intelligent information monitoring systems, including , use AI technology to add "insight" to the production of sand and gravel aggregates.

“Based on our more than 4 years of practice and continuous research, we have found that when sand and gravel aggregates are processed in a factory, there will be problems such as data lag during indoor monitoring and human factors making it difficult to control the quality of the production process. We have passed the latest With the developed monitoring system, the repeatability error and accuracy error of the detection results have reached a high precision of less than 3%. We have also developed low-cost, low-energy consumption intelligent perception dust suppression equipment to achieve the total dust efficiency of machine-made aggregate processing plants The dust removal rate of respiratory dust reached 98%. The environmental protection standards of production and processing have been further improved. " said Liu Hailin, a participant in this technology project and a post-85s generation deputy general manager of China Railway Fourth Bureau Materials Company.

Editor | Yang Haowei · Review | Yang Xiaodong

Source: China Youth Daily

Statement: Some of the article materials and materials used in this subscription account are from the Internet and are for learning and communication purposes only. There is no intention to infringe copyright. If there is any offense, please contact us to delete it, thank you for your understanding

The above is the detailed content of State-owned enterprises use artificial intelligence technology to realize intelligent improvements in sand and gravel aggregate production. For more information, please follow other related articles on the PHP Chinese website!

Tesla's Robovan Was The Hidden Gem In 2024's Robotaxi TeaserApr 22, 2025 am 11:48 AM

Tesla's Robovan Was The Hidden Gem In 2024's Robotaxi TeaserApr 22, 2025 am 11:48 AMSince 2008, I've championed the shared-ride van—initially dubbed the "robotjitney," later the "vansit"—as the future of urban transportation. I foresee these vehicles as the 21st century's next-generation transit solution, surpas

Sam's Club Bets On AI To Eliminate Receipt Checks And Enhance RetailApr 22, 2025 am 11:29 AM

Sam's Club Bets On AI To Eliminate Receipt Checks And Enhance RetailApr 22, 2025 am 11:29 AMRevolutionizing the Checkout Experience Sam's Club's innovative "Just Go" system builds on its existing AI-powered "Scan & Go" technology, allowing members to scan purchases via the Sam's Club app during their shopping trip.

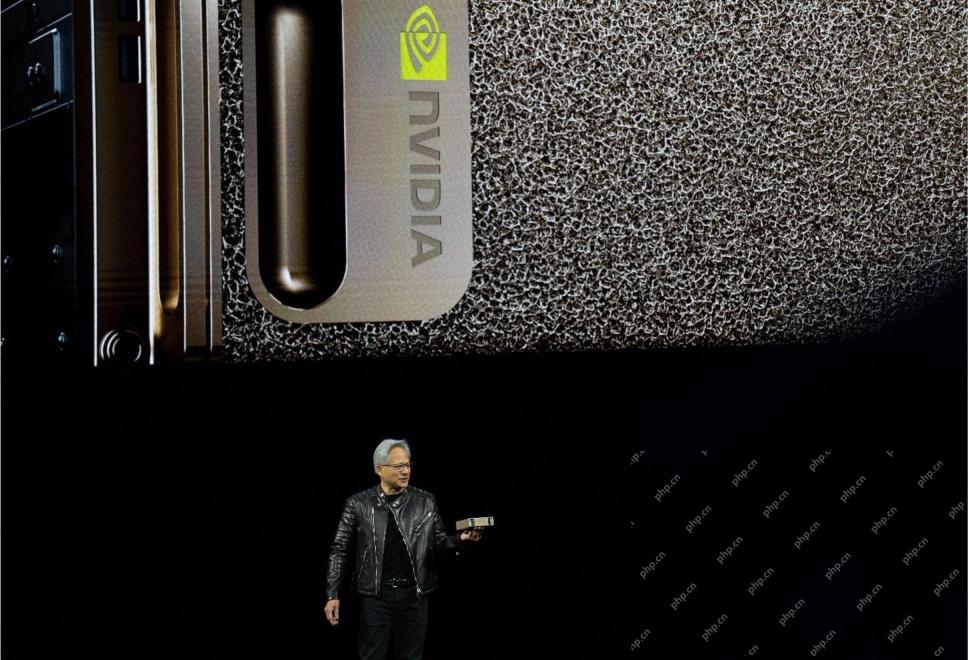

Nvidia's AI Omniverse Expands At GTC 2025Apr 22, 2025 am 11:28 AM

Nvidia's AI Omniverse Expands At GTC 2025Apr 22, 2025 am 11:28 AMNvidia's Enhanced Predictability and New Product Lineup at GTC 2025 Nvidia, a key player in AI infrastructure, is focusing on increased predictability for its clients. This involves consistent product delivery, meeting performance expectations, and

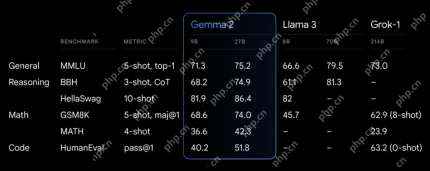

Exploring the Capabilities of Google's Gemma 2 ModelsApr 22, 2025 am 11:26 AM

Exploring the Capabilities of Google's Gemma 2 ModelsApr 22, 2025 am 11:26 AMGoogle's Gemma 2: A Powerful, Efficient Language Model Google's Gemma family of language models, celebrated for efficiency and performance, has expanded with the arrival of Gemma 2. This latest release comprises two models: a 27-billion parameter ver

The Next Wave of GenAI: Perspectives with Dr. Kirk Borne - Analytics VidhyaApr 22, 2025 am 11:21 AM

The Next Wave of GenAI: Perspectives with Dr. Kirk Borne - Analytics VidhyaApr 22, 2025 am 11:21 AMThis Leading with Data episode features Dr. Kirk Borne, a leading data scientist, astrophysicist, and TEDx speaker. A renowned expert in big data, AI, and machine learning, Dr. Borne offers invaluable insights into the current state and future traje

AI For Runners And Athletes: We're Making Excellent ProgressApr 22, 2025 am 11:12 AM

AI For Runners And Athletes: We're Making Excellent ProgressApr 22, 2025 am 11:12 AMThere were some very insightful perspectives in this speech—background information about engineering that showed us why artificial intelligence is so good at supporting people’s physical exercise. I will outline a core idea from each contributor’s perspective to demonstrate three design aspects that are an important part of our exploration of the application of artificial intelligence in sports. Edge devices and raw personal data This idea about artificial intelligence actually contains two components—one related to where we place large language models and the other is related to the differences between our human language and the language that our vital signs “express” when measured in real time. Alexander Amini knows a lot about running and tennis, but he still

Jamie Engstrom On Technology, Talent And Transformation At CaterpillarApr 22, 2025 am 11:10 AM

Jamie Engstrom On Technology, Talent And Transformation At CaterpillarApr 22, 2025 am 11:10 AMCaterpillar's Chief Information Officer and Senior Vice President of IT, Jamie Engstrom, leads a global team of over 2,200 IT professionals across 28 countries. With 26 years at Caterpillar, including four and a half years in her current role, Engst

New Google Photos Update Makes Any Photo Pop With Ultra HDR QualityApr 22, 2025 am 11:09 AM

New Google Photos Update Makes Any Photo Pop With Ultra HDR QualityApr 22, 2025 am 11:09 AMGoogle Photos' New Ultra HDR Tool: A Quick Guide Enhance your photos with Google Photos' new Ultra HDR tool, transforming standard images into vibrant, high-dynamic-range masterpieces. Ideal for social media, this tool boosts the impact of any photo,

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

Dreamweaver Mac version

Visual web development tools

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software