Technology peripherals

Technology peripherals AI

AI Industrial robots are ushering in the transformation from manufacturing to intelligent manufacturing in the region

Industrial robots are ushering in the transformation from manufacturing to intelligent manufacturing in the regionwhip牛士 According to news on November 17, industrial robots such as welding and spray painting are flexing their arms in the workshops of new energy vehicles, photovoltaic manufacturing, lithium battery manufacturing and other emerging industries. In a new round of scientific and technological revolution and industrial transformation that are accelerating, as a key carrier of emerging technologies and an important starting point for the transformation of the manufacturing industry, industrial robots are profoundly affecting global technological innovation and industrial structure adjustment, and have also become a rush to increase investment among regions. new track.

Tianyancha data shows that there are more than 231,000 industrial robot-related companies in existence, of which more than 22,000 were newly registered from January to October 2023; from the perspective of geographical distribution, related companies in Guangdong, Jiangsu and Shandong The number ranks among the top. Among them, Jiangsu "leads" among the provinces with more than 42,000 related companies, followed closely by Guangdong and Shandong, with more than 38,000 and more than 23,000 related companies respectively.

It is worth noting that areas with a high concentration of industrial robot-related companies have relatively complete industrial scale, industrial chain ecological layout, urban supporting facilities, talent training and attraction, and policy mechanisms. For example, Jiangsu, Zhejiang, Guangdong and other regions all have representative companies in the industrial robot industry chain, and play a key role in assisting the transformation and upgrading of "manufacturing provinces".

The development momentum is very strong, and industrial clusters have been formed in the country

The world’s first programmable robot was born in the United States and was first used in an industrial site in 1961. However, robots at the time could only be used for simple handling and repetitive tasks. In 1973, Japan's Hitachi developed a robot with dynamic vision and began to be equipped with a microprocessor, which was widely used in industry. Nowadays, modern robots already have decision-making and computing capabilities, and the development of robots has entered the era of intelligence

The "China Robot Technology and Industry Development Report (2023)" points out that with the rapid development of robot technology and the continuous exploration of market potential, the global robot industry maintains a growth trend, and China has become an important driving force for the development of the robot industry.

"With the joint efforts of all parties, China's robot industry has developed strongly, ranking first in the world in scale. Basic core technologies have continued to make breakthroughs. Artificial intelligence has entered the first echelon of the world, laying the foundation for the development of the humanoid robot industry. We have laid a solid foundation." On August 18, at a sub-forum of the 2023 World Robot Conference, Xu Xiaolan, Vice Minister of the Ministry of Industry and Information Technology, said.

China’s huge manufacturing industry has given birth to the world’s largest industrial robot market. Since 2013, China has occupied the world’s largest industrial robot consumer market for many years. In 2022, the revenue of China's robot industry will exceed 170 billion yuan, continuing to maintain double-digit growth; industrial robot sales account for more than half of the world's sales, and the density of manufacturing robots will reach 392 units per 10,000 workers.

With the continuous development of the robot industry, China has formed industrial clusters with unique characteristics

The aforementioned "Report" pointed out that from the perspective of the distribution of national-level specialized and new "little giant" enterprises and listed enterprises in the field of robotics, China's high-quality robotics enterprises are mainly distributed in the Beijing-Tianjin-Hebei, Yangtze River Delta, and Pearl River Delta regions, forming a Industrial clusters represented by Beijing, Shenzhen, Shanghai, Dongguan, Hangzhou, Tianjin, Suzhou, Foshan, Guangzhou, Qingdao, etc.

According to the "Report", Beijing, Shenzhen and Shanghai have strong strengths in the robot industry, while the robot industries in Dongguan, Hangzhou, Tianjin, Suzhou and Foshan are gradually developing and growing. The development potential of the robot industry in Guangzhou and Qingdao is also considerable

Regional registration: application demand drives industry scale growth

According to public data, in 2022, the company with the highest sales of industrial robots in China is Eston in Jiangsu Province, with annual sales of more than 17,000 units; while Inovance Technology in Guangdong Province has strong advantages in servo systems and control systems. In recent years, it has been catching up in the field of industrial robots, with sales second only to Eston.

In fact, in the comprehensive strength of the industrial robot industry, the Yangtze River Delta can be regarded as "far ahead". The Yangtze River Delta is one of the most economically developed regions in China and an important advanced manufacturing base in China. The vigorous economic development of the region has provided important technology, talent, capital, information and other industrial resource support and application expansion areas for the robot and intelligent manufacturing equipment industry.

At present, the Yangtze River Delta region has gathered a number of well-known international and domestic robot manufacturing companies and application companies, and the regional robot production capacity accounts for more than 50% of the country's total. In addition to the four well-known international brands such as ABB, FANUC, KUKA, and Yaskawa Robotics, there are also Chinese brands such as Xinshida, Eston, and Eft, as well as independent brands such as Jika Robot, which has risen rapidly in recent years.

The demand for industrial robot applications in the Pearl River Delta region has promoted the continued expansion of industrial scale, with key industrial agglomeration areas ranking at the forefront. The three cities of Guangzhou, Foshan and Shenzhen are one of the most active areas in the development of the robot industry in the country, and the robot industry has obvious advantages. At present, the robot industry in these cities is continuously developing towards intelligence, high-end and integration

For example, Shenzhen focuses on smart manufacturing and promotes the improvement of the intelligent level of robots; Guangzhou takes advantage of its geographical advantages to vigorously develop high-end robot applications; Foshan relies on its own advantages to build a high-end robot manufacturing base. By continuously promoting the demonstration application of industrial robots in high-end manufacturing and traditional pillar industries, the Pearl River Delta region is deeply exploring the commercial service robot track.

In contrast, Beijing-Tianjin-Hebei is not the region with the largest domestic robot industry, but the development quality and added value of the robot industry are relatively high. In recent years, with the strong guidance and support of national policies, relying on outstanding location advantages and good manufacturing foundation, the robot industries in Beijing, Tianjin, and Hebei in the Beijing-Tianjin-Hebei region have formed a good situation of misaligned competition and complementary advantages.

With the support of the local new generation information technology industry, the industrial robot industry in Beijing, Tianjin and Hebei has gradually moved up to the middle and high end of the value chain.

Assist in promoting the industrial transformation and upgrading of the "Manufacturing Province"

By 2025, the scale of the robot industry in Shandong Province will reach 50 billion yuan, and the average annual growth rate of industrial robot output will exceed 25%

This is a development goal during Shandong’s “14th Five-Year Plan” period. In line with this goal, Shandong will create more than 40 individual champions and specialized new enterprises in the field of robotics, cultivate a number of typical application scenarios, add more than 100 smart factories and digital workshops every year, and increase the coverage of robot applications in key areas. Significant improvement.

At the beginning of 2023, the Ministry of Industry and Information Technology released the "Implementation Plan for the "Robot" Application Action", which clearly stated that in the manufacturing field, it is necessary to promote the construction of intelligent manufacturing demonstration factories and create typical application scenarios for industrial robots. At the same time, it is also necessary to develop intelligent manufacturing systems based on industrial robots to help the manufacturing industry achieve digital transformation and intelligent change

The "China Robot Industry Development Report (2022)" shows that robots and automation have become an integral part of modern manufacturing in the past few years, with manufacturers integrating robotic systems in production facilities to increase production capacity and increase profits. efficiency and reduce operating costs. Industrial robots will also play an increasingly important role in the industrial transformation and upgrading of major manufacturing provinces.

Patents may serve as a breakthrough.

As a technology-intensive industry, the number of applications for industrial robot patent technology can reveal the scientific and technological content and level of industrial development. According to data from Tianyancha, judging from the total number of patent applications for industrial robots, the number of patent applications has exceeded 10,000. Among them, there are more than 6,200 utility model patents, ranking first; there are more than 5,100 invention patents, ranking second; there are more than 880 design patents, ranking third

As a treasure in the field of intelligent manufacturing, industrial robots have always attracted the attention of venture capital institutions. According to data from Tianyancha, judging from the industry distribution of financing events, the number of financing events related to robots ranks among the top, with 60 cases; in addition, downstream application fields closely related to industrial robots such as intelligent equipment, logistics equipment, and warehousing services It is also a hot spot for investment and financing

Specifically, Jiangsu, Shanghai, and Guangdong rank among the top three places in terms of the number of financing events, with 16 (Jiangsu and Shanghai are tied) and 15 respectively; from a city perspective, Shenzhen, Nanjing, and Hefei have There are a large number of financing events, 11, 10 and 4 respectively. Judging from the geographical distribution of financing events, it can be clearly seen that the relationship between industrial robots and strong manufacturing provinces is very close, which strongly supports the upgrading of the manufacturing industry

The above is the detailed content of Industrial robots are ushering in the transformation from manufacturing to intelligent manufacturing in the region. For more information, please follow other related articles on the PHP Chinese website!

Reading The AI Index 2025: Is AI Your Friend, Foe, Or Co-Pilot?Apr 11, 2025 pm 12:13 PM

Reading The AI Index 2025: Is AI Your Friend, Foe, Or Co-Pilot?Apr 11, 2025 pm 12:13 PMThe 2025 Artificial Intelligence Index Report released by the Stanford University Institute for Human-Oriented Artificial Intelligence provides a good overview of the ongoing artificial intelligence revolution. Let’s interpret it in four simple concepts: cognition (understand what is happening), appreciation (seeing benefits), acceptance (face challenges), and responsibility (find our responsibilities). Cognition: Artificial intelligence is everywhere and is developing rapidly We need to be keenly aware of how quickly artificial intelligence is developing and spreading. Artificial intelligence systems are constantly improving, achieving excellent results in math and complex thinking tests, and just a year ago they failed miserably in these tests. Imagine AI solving complex coding problems or graduate-level scientific problems – since 2023

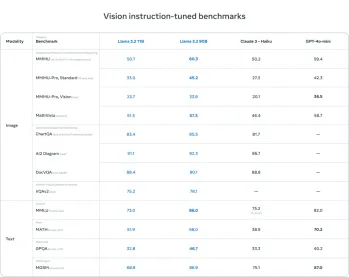

Getting Started With Meta Llama 3.2 - Analytics VidhyaApr 11, 2025 pm 12:04 PM

Getting Started With Meta Llama 3.2 - Analytics VidhyaApr 11, 2025 pm 12:04 PMMeta's Llama 3.2: A Leap Forward in Multimodal and Mobile AI Meta recently unveiled Llama 3.2, a significant advancement in AI featuring powerful vision capabilities and lightweight text models optimized for mobile devices. Building on the success o

AV Bytes: Meta's Llama 3.2, Google's Gemini 1.5, and MoreApr 11, 2025 pm 12:01 PM

AV Bytes: Meta's Llama 3.2, Google's Gemini 1.5, and MoreApr 11, 2025 pm 12:01 PMThis week's AI landscape: A whirlwind of advancements, ethical considerations, and regulatory debates. Major players like OpenAI, Google, Meta, and Microsoft have unleashed a torrent of updates, from groundbreaking new models to crucial shifts in le

The Human Cost Of Talking To Machines: Can A Chatbot Really Care?Apr 11, 2025 pm 12:00 PM

The Human Cost Of Talking To Machines: Can A Chatbot Really Care?Apr 11, 2025 pm 12:00 PMThe comforting illusion of connection: Are we truly flourishing in our relationships with AI? This question challenged the optimistic tone of MIT Media Lab's "Advancing Humans with AI (AHA)" symposium. While the event showcased cutting-edg

Understanding SciPy Library in PythonApr 11, 2025 am 11:57 AM

Understanding SciPy Library in PythonApr 11, 2025 am 11:57 AMIntroduction Imagine you're a scientist or engineer tackling complex problems – differential equations, optimization challenges, or Fourier analysis. Python's ease of use and graphics capabilities are appealing, but these tasks demand powerful tools

3 Methods to Run Llama 3.2 - Analytics VidhyaApr 11, 2025 am 11:56 AM

3 Methods to Run Llama 3.2 - Analytics VidhyaApr 11, 2025 am 11:56 AMMeta's Llama 3.2: A Multimodal AI Powerhouse Meta's latest multimodal model, Llama 3.2, represents a significant advancement in AI, boasting enhanced language comprehension, improved accuracy, and superior text generation capabilities. Its ability t

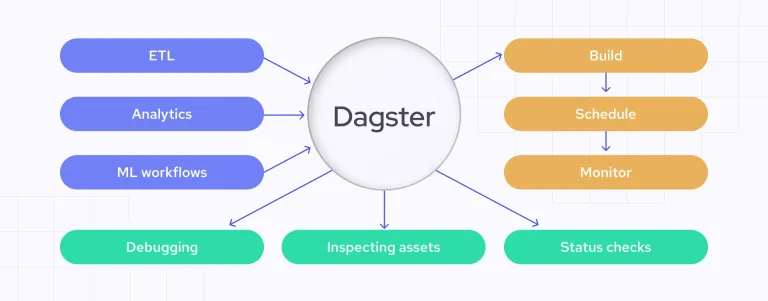

Automating Data Quality Checks with DagsterApr 11, 2025 am 11:44 AM

Automating Data Quality Checks with DagsterApr 11, 2025 am 11:44 AMData Quality Assurance: Automating Checks with Dagster and Great Expectations Maintaining high data quality is critical for data-driven businesses. As data volumes and sources increase, manual quality control becomes inefficient and prone to errors.

Do Mainframes Have A Role In The AI Era?Apr 11, 2025 am 11:42 AM

Do Mainframes Have A Role In The AI Era?Apr 11, 2025 am 11:42 AMMainframes: The Unsung Heroes of the AI Revolution While servers excel at general-purpose applications and handling multiple clients, mainframes are built for high-volume, mission-critical tasks. These powerful systems are frequently found in heavil

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

Dreamweaver Mac version

Visual web development tools

Zend Studio 13.0.1

Powerful PHP integrated development environment