Technology peripherals

Technology peripherals AI

AI A new chapter in the 'Pivot' of Exploring Yuan Universe丨iSoftStone Industrial Yuan Universe 2023 Innovation and Development Forum was successfully held

A new chapter in the 'Pivot' of Exploring Yuan Universe丨iSoftStone Industrial Yuan Universe 2023 Innovation and Development Forum was successfully heldOn October 28, with the strong support and guidance of Nanjing Jiangning High-tech Zone, the Industrial Metaverse of iSoftStone was hosted by iSoftStone and co-organized by Nanjing Xiaozhuang College, iSoftStone Education and iSoftStone Tianshu Metaverse Research Institute The 2023 Innovation and Development Forum was held in Nanjing. The forum is titled “Exploring a New Chapter of the ‘Pivot’ of the Metaverse”, aiming to explore the technological development trends and industrial applications of the Metaverse and digital twins, and promote the accelerated implementation of the industrial Metaverse. At the forum, iSoftStone launched a newly upgraded industrial digital twin base platform - Tianshu iSSMeta2023.

Liu Guangfu, Director of the Management Committee of Jiangning High-tech Zone, Shi Youkang, Deputy Chief Engineer of China Academy of Information and Communications Technology, Zhao Xiangjun, Vice President of Nanjing Xiaozhuang College, and representatives from Southeast University, Nanjing Normal University, Jiangning High-tech Zone Venture Capital Company, SAP, BSI, Tencent Experts and scholars from Cloud, JD.com, Dahua Technology, Shengjing Jiacheng, Siji Muge, Nanjing Lingjing Yuanshi Research Institute, Wei Zhanshi and more than 100 customer partners, together with iSoftStone CTO Liu Huifu, Senior Vice President and iSoftStone Education CEO Lin Tao, Senior Vice President of Digital Innovation Service Line and General Manager of iSoftStone Consulting Yang Niannong, Vice President and Vice President of the Technology Research Institute Luo Dongmei attended this forum.

Director Liu Guangfu delivered a speech on the policy layout of Jiangning High-tech Zone in the field of metaverse and the latest progress of the "metaverse industry pilot zone". He said that the holding of the Industrial Metaverse Innovation and Development Forum this time is a reflection of iSoftStone's active participation in the co-creation, co-construction and integration of the metaverse industry in the park. It is also a leading enterprise that assumes the responsibility of taking the lead in promoting the development of the industrial metaverse subdivisions. . Building an industrial metaverse requires the joint efforts of friends in the industry. I hope everyone will make full use of today's platform to jointly promote collaborative innovation and development in the field of data and entity integration

Zhao Xiangjun, vice president of Nanjing Xiaozhuang University, said in his speech that in recent years, the School of Information Engineering and the School of Artificial Intelligence of Nanjing Xiaozhuang University have focused on "artificial intelligence education" and have more than 10 provincial and municipal platforms. The Artificial Intelligence Education Industry College jointly built by the college and iSoftStone explores industry demand-oriented, strengthens multi-subject collaborative education, and strives to build a college that integrates functions such as talent training, scientific research, technological innovation, achievement incubation, and student entrepreneurship. An exemplary talent training entity, serving the development of local artificial intelligence and education industries, and exploring the Xiaozhuang model for cultivating new engineering talents. We look forward to deepening cooperation with all parties and working together to build a new ecosystem for the Metaverse.

Liu Huifu warmly welcomed the guests present and expressed his gratitude to Jiangning High-tech Zone for its continuous support. He said that driven by technology and the leading effect, the industrial metaverse will usher in rapid growth and become the new focus of industrial digitalization. iSoftStone began to lay out and invest in the industrial metaverse as early as 2015, and has built a complete Tianshu iSSMeta 1 6 N product system, created a localized independent and controllable digital twin platform, and successfully provided more than 100 customers with service. In the future, iSoftStone will continue to improve its technical capabilities, provide customers with scenario-oriented Metaverse solutions, and work with partners to build the Metaverse industrial ecosystem and share innovation results

Major release Tianshu iSSMeta is upgraded again

The Tianshu iSSMeta2023 product launch ceremony was held at the forum. Shi Youkang, deputy chief engineer of China Academy of Information and Communications Technology, Guo Fangpeng, general manager of Jiangning High-tech Zone Science and Technology Venture Capital Co., Ltd., Liu Huifu, iSoftStone CTO, iSoftStone vice president and deputy director of the Technology Research Institute Dean Luo Dongmei and Assistant Vice President of Major Customer Business Group Yao Wen jointly took the stage to launch Tianshu iSSMeta2023.

At the same time, Tianshu iSSMeta-industrial dual-carbon metaverse solution was also released. Guo Fangpeng, general manager of Jiangning High-tech Zone Science and Technology Venture Capital Company, Qiu Yan, business director of SAP China's business technology cloud platform, Xiang Zhenzhen, director of standard application solutions for BSI Southeast Region, senior vice president of iSoftStone Digital Innovation Service Line and general manager of iSoftStone Consulting Yang Niannong and Luo Dongmei, vice president of iSoftStone and deputy director of the Technology Research Institute, jointly launched the plan release.

In this forum, iSoftStone Education and Nanjing Xiaozhuang College reached cooperation. Both parties will give full play to their respective advantages, deeply integrate school and enterprise resources, cooperate to build an artificial intelligence education industry college, and develop and prosper the artificial intelligence talent training ecosystem. Zheng Hao, Dean of the School of Information Engineering & Artificial Intelligence of Nanjing Xiaozhuang University, and Jiang Pianhong, Assistant Vice President of iSoftStone signed the cooperation agreement as representatives of both parties. Zhao Xiangjun, Vice President of Nanjing Xiaozhuang University, Liu Huifu, CTO of iSoftStone, and Senior Vice President of iSoftStone Lin Tao, Vice President and CEO of iSoftStone Education, also witnessed the event.

Big names gathered to discuss the "Industrial Metaverse"

Shi Youkang, deputy chief engineer of the China Academy of Information and Communications Technology, said in a keynote speech titled "Industrial Digital Twin Technology and Application Development Trends" that digital twins are becoming a new focus in the development of global digital technology. Industrial digital twins are in line with my country's information technology The strategic need for technology to empower industrial transformation and upgrading has become one of the key enabling technologies. For industrial digital twins, data is the foundation, the model is the core, and software is the carrier. The three major elements to measure the development level of digital twins are twin accuracy, time and space. He emphasized that industrial digital twins are only in their infancy, and truly mature digital twin applications will take a longer period of time to explore and practice. Combination methods such as "Industrial Internet Platform MBSE" and "Industrial Internet Platform Management Shell" are expected to become important methods for the development of industrial digital twins. Asset digitization is the source of digital twin development. Industrial manufacturers’ accumulated awareness of twin data and twin models will indirectly determine the value of digital twins in the future.

Liu Tingyu, associate professor and doctoral supervisor at the School of Mechanical Engineering of Southeast University, delivered a speech titled "Intelligent Manufacturing Process Control Based on Digital Twins", explaining in detail the accelerated integration of emerging technologies and advanced manufacturing technologies, as well as the practice of digital twins in the field of intelligent manufacturing. . Professor Liu pointed out that digital twins are an effective way to realize intelligent manufacturing, and demonstrated implementation cases of intelligent manufacturing practices based on digital twins, including intelligent control systems for the digital assembly process of aerospace equipment, LEIDA intelligent assembly systems based on digital twins, etc., which were comprehensive and in-depth The company thoroughly shared the digital twin-driven intelligent manufacturing model, providing important reference and guidance for the industry.

Mou Lei, general manager of Tencent Cloud's digital twin product ecology, pointed out in the keynote speech "Real-time Twins Drive Lean Development of Industrial Digitalization" that digital twins are the core cornerstone of "Full-True Internet" and will provide a comprehensive view of the physical world for Quan-True Internet. Ability to restore, connect, feedback, control, etc. It also proposes five twin maturity levels from digitalization to shared intelligence, and an industrial high-quality development paradigm based on these. Through the real-time twin construction of production processes, production schedules, material transportation, equipment management, lean production and other scenarios, it can efficiently drive the lean development of industrial digitalization and help the manufacturing industry upgrade. She introduced that Tencent provides digital twin bases, visualization platforms, spatial real-time computing platforms, and real-time simulation platforms, which can help customers realize digital twin applications that are beautiful, computable, easy to manage, and easy to control. We also hope to open up the accumulated common capabilities to industry partners, form a wide range of ecological partners, and create a win-win situation for China's digital economy.

Sang Tian, senior product manager of JD Logistics, delivered a keynote speech titled "Using Digital Twins and AI Technology to Transform Logistics and Warehousing", sharing the core functions, highlights and successful cases of JD Logistics. She said that JD.com is positioned as a one-stop technical tool for warehousing digital intelligence, and provides one-stop services of hardware, platform, and software to address the pain points of logistics and warehousing management. Through technical tools covering the entire process of collection, analysis, insight, and intelligent control, we have built a variety of warehousing digital intelligence solutions, including warehousing 3D digital twin planning, 3D digital twin monitoring, AIOT supervision warehouses, etc., to help customers achieve a closed loop of value. In the case of intelligent analysis of automation scenarios, based on the full collection of automated site equipment data and data analysis, twin insights can be used to view key indicators and trends of equipment operation anytime and anywhere, predict abnormalities, and achieve cost reduction and efficiency improvement.

Zhou Erkang, Director of the Intelligent Manufacturing Development Department of Zhejiang Dahua Technology Co., Ltd., introduced in detail the overall solution of Dahua Intelligent IoT Factory with the title of "Sharing of Intelligent Manufacturing Capabilities Based on the Construction Needs of 'Future Factory'". He said that Dahua Technology has experienced a complete path from employee manual work to automated smart factories, and has accumulated cross-domain and interdisciplinary knowledge and experience on the journey of digital automation. The focus is on the Dahua Smart IoT Factory Management Platform, which uses the industrial Internet to obtain real-time industrial data of equipment and provides an Equipment Health Management Platform (EHM) and a Production Digital Management Platform (MDP). It can be deeply integrated with MES, WMS, big data and cloud platforms to achieve effective interconnection, intelligent analysis, early warning and prediction of intelligent production equipment. The integration of materials and information will comprehensively create a smart, IoT-connected intelligent production factory. In general, Dahua can provide integrated software and hardware solutions for intelligent manufacturing, helping companies improve their “hard power” in production.

Zhong Ming, founder and CEO of Wei Zhanshi (Beijing) Digital Technology Co., Ltd., gave a speech titled "Seeing the Value of the Industrial Metaverse", comprehensively explaining the technological changes in industrial digitalization and the huge value of three-dimensional visualization data to industrial digitalization. . He pointed out that the industrial metaverse and space computing are the next driving forces for human economic growth. The three-dimensional visualization of products and processes has naturally become the best connection interface for the industrial metaverse and space computing. The use of three-dimensional visualization technology can help companies learn from their products. Start with digitalization and connect data to drive the entire business process. Therefore, three-dimensional visualization data is the best entry point for industrial digitization. In his speech, he listed the best practices of micro-display in the fields of product promotion, after-service and production line digitization, as well as how to help customers succeed through 3D visualization.

In-depth interpretation and best practices of Tianshu iSSMeta

Yuan Zhenjie, chief architect of iSoftStone Industrial Digital Lisheng Research Center, explains Tianshu iSSMeta2023 new product. iSSMeta2023 focuses on industrial digital twins. Driven by core technologies such as graphics rendering engine, twin simulation theme data management, and industrial simulation, it provides a new generation of digital products for industrial production line safety supervision, production, R&D, manufacturing, and testing, and can provide customers with comprehensive Stacked industrial iSSMeta solutions and technical services. The new product has achieved significant results in the five core capabilities of "AIGC-based automatic modeling", "industrial mechanism model configuration analysis", "industrial design simulation CAE and process simulation", "flexible intelligent management and control engine", and "industrial digital twin aPaaS base". Pound upgrade. Facing the future, iSSMeta2024 will make efforts in the fields of factory design and production simulation, the combination of AI and digital twins, and industrial CAE applications, build a more comprehensive base platform for the entire chain of industrial manufacturing, and lead China's industrial digital twin innovation.

Gao Guohui, head of business development and promotion of BTP ecological partners in SAP Greater China, introduced SAP's first carbon accounting management and sustainable development solution based on detailed business. Focused on sharing how SAP, BSI and iSoftStone work together to help companies go overseas and navigate into the carbon era. Based on the SAP BTP technology base, BSI standard authoritative certification, and iSoftStone’s professional consulting and implementation, the three parties jointly innovated to create a digital carbon management platform to provide enterprises with the carbon management capabilities they actually need.

Jiao Danhua, senior product manager of iSoftStone, explained in detail the iSSMeta-Green2023 carbon intelligent management platform of iSoftStone Tianshu. This product system is built on the Tianshu iSSMeta platform and multiple cloud infrastructures, providing comprehensive carbon intelligence services covering carbon calculation, carbon footprint, calculation model, carbon ledger, carbon trading, etc. Its core advantage is the metaverse and strategy simulation. iSoftStone has built a "5 6 N" system around the carbon platform. "5" represents the five basic supports: iSoftStone Consulting, iSoftStone ESG digital integration platform, State Grid Credit Information, iSoftStone Education, and Carbon Technology Company; "6" "Refers to six major extended services: carbon consulting, carbon operations, carbon training, carbon market, carbon ledger, ESG consulting and reporting services, in addition to N subdivided services.

Gong Baojia, product manager of iSoftStone's EME Energy Manufacturing and Emerging Industries Business Group, shared that Tianshu iSSMeta-digital intelligent π warehouse is mainly based on digital twins to deal with comprehensive digital business solutions for warehousing, focusing on intelligent management of warehousing operations, all aspects Improve operational efficiency in the warehousing field and reduce warehousing operating costs in all aspects. This product breaks the traditional warehousing digital operation and management model, turns "numbers" into "things", integrates data with real scenarios, and comprehensively upgrades the traditional digital management model to the innovative application of space situation control, helping warehousing companies to efficiently respond to warehousing safety and stability Operations, users can track and conduct business operations at any time through the global dynamic 360° panoramic view, helping enterprises to achieve visual perception of business situation beforehand, dynamic optimization tracking and execution during the process, and visual traceability of real scenes after the event. Real-time supervision of safety and operating equipment, truly ensuring 24/7 escort.

Wang Qiang, senior department director of the Park Business Department of iSoftStone, is explaining the Tianshu iSSMeta-Campus Edition product. The architecture of this product consists of four levels: "device subsystem, network, platform, IOC business application". Among them, the 3D GIS engine of the smart campus AI brain has been upgraded to the iSSMeta metaverse base, which significantly improves the running speed and visualization effect. This product can realize digital mapping of the real world and digitize objects by visually displaying campus personnel, vehicles and object resources. By highly integrating the processes, responsibilities and rules required for incident handling, experience assets are solidified and processes are digitized. With the help of AI-assisted analysis and decision-making, we can provide reasonable prediction suggestions for campus operation management, realize the digitization of operations, and ultimately realize a fully digital smart campus

In the roundtable dialogue session, Yang Niannong served as the senior vice president of iSoftStone’s digital innovation service line and the general manager of iSoftStone Consulting; Zheng Hao was the dean of the School of Information Engineering and the School of Artificial Intelligence of Nanjing Xiaozhuang University; Zhong Ming was the director of Weizhanshi The founder and CEO of (Beijing) Digital Technology Co., Ltd., Yu Dayong is the vice president and general manager of the comprehensive energy division of Siji Muge, and Cao Zhou is the director of the Yuanverse Laboratory of Nanjing Lingjing Engine Technology Co., Ltd. They conducted exchanges around "Yuanverse technology development trends and industrial applications"

Taking this forum as an opportunity, iSoftStone will rely on Tianshu Metaverse Research Institute to continue to deepen the exploration and innovation of industrial metaverse technology and application scenarios, deepen cooperation with all parties in the industry, and promote the prosperity and development of the metaverse industry. Promote new industrialization.

The above is the detailed content of A new chapter in the 'Pivot' of Exploring Yuan Universe丨iSoftStone Industrial Yuan Universe 2023 Innovation and Development Forum was successfully held. For more information, please follow other related articles on the PHP Chinese website!

We explain how to create a FAQ using ChatGPT! For internal FAQs and customer serviceMay 16, 2025 am 05:19 AM

We explain how to create a FAQ using ChatGPT! For internal FAQs and customer serviceMay 16, 2025 am 05:19 AMThis article will explain in detail how to create a FAQ using ChatGPT. We will introduce how to maximize the potential of ChatGPT, including specific steps and examples, to create FAQs that will help you improve customer service efficiency. By comprehensively explaining the advantages and disadvantages of automatically generating FAQs using ChatGPT, as well as points to be careful about, we will contribute to improving the quality of customer support and, ultimately, to improve business efficiency. Click here for more information about OpenAI's latest AI agent, OpenAI Deep Research ⬇️ [ChatGPT] OpenAI D

Cadence Unveils Millennium M2000 Supercomputer And Nvidia Is All InMay 16, 2025 am 05:18 AM

Cadence Unveils Millennium M2000 Supercomputer And Nvidia Is All InMay 16, 2025 am 05:18 AMBuilt in collaboration with Nvidia, and leveraging the latter’s latest Blackwell GPU architecture, the M2000 is more than a spec sheet upgrade—it’s a structural shift in how simulation infrastructure is architected. Cadence’s flagship Solvers for chi

What are the ChatGPT information leaks cases? Explaining actual cases and countermeasuresMay 16, 2025 am 05:17 AM

What are the ChatGPT information leaks cases? Explaining actual cases and countermeasuresMay 16, 2025 am 05:17 AMChatGPT's information leakage risks and response measures This article discusses the risks of using ChatGPT and how to reduce the possibility of information leakage. ChatGPT's information leakage risk Using ChatGPT may face several information leakage risks: Confidential information contained in the training profile may be reflected in the reply. Confidential information entered by the user may be stored in the system and may be at risk of leakage. ChatGPT's database may be subject to cyber attacks, resulting in user information and dialogue records being stolen. These risks stem from how ChatGPT is designed and operated. OpenAI is committed to protecting user privacy and information, but it also clearly states that user data may be used in order to improve the service. therefore

What is GPT-3? Explaining the differences between GPT-4, fees, and number of parametersMay 16, 2025 am 05:14 AM

What is GPT-3? Explaining the differences between GPT-4, fees, and number of parametersMay 16, 2025 am 05:14 AMIn recent years, artificial intelligence natural language processing technology has made significant progress, and the GPT-3 model developed by OpenAI is at a core position. GPT-3 uses unprecedented massive data sets and huge parameters to achieve natural and smooth text generation capabilities. This article will explore GPT-3 in depth, covering its basic information, development background, reasons for its high attention, and its differences from subsequent models GPT-3.5 and GPT-4. In addition, we will introduce how these technologies are priced and widely used to help readers understand the cutting-edge dynamics of artificial intelligence. OpenAI's latest AI agent, "OpenAI Deep Research", please click the link below for details: 【ChatGPT】OpenAI

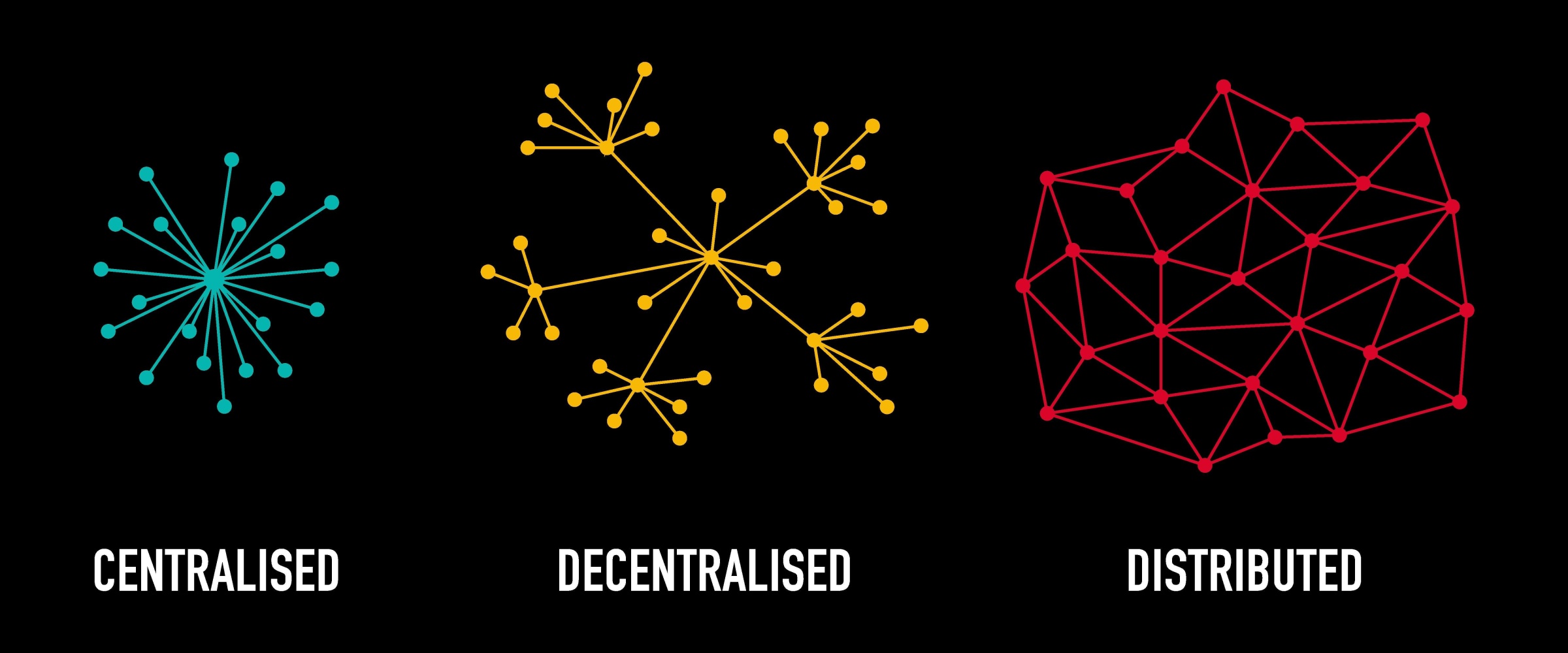

Make A Decentralized Internet, With AI: NANDA Is ComingMay 16, 2025 am 05:11 AM

Make A Decentralized Internet, With AI: NANDA Is ComingMay 16, 2025 am 05:11 AMMany experts who speak at modern conferences and write papers on large language models (LLMs) will agree that we need to understand why things work in some way and how to leverage them. Benjamin Franklin made history by putting the metallic system on the rope and thinking about why Lightning works like this. He was a member of the philosophy circle at that time. We need something similar. With that in mind, I was impressed by Abhishek Singh’s speech on “The Future of Chaos, Coordination and Agent AI” at an April event. Decentralized Network Singh is one of many researchers working on the basic concept of decentralized networking and how this relates to the new technologies we have. In his speech, he talked about continuity, heterogeneity

What should you not do with ChatGPT? Explaining important things to avoidMay 16, 2025 am 05:08 AM

What should you not do with ChatGPT? Explaining important things to avoidMay 16, 2025 am 05:08 AMAI text generation tools such as ChatGPT are becoming increasingly popular, and their convenience is unquestionable, but you need to be cautious when using them. This article will elaborate on the precautions for safe and effective use of ChatGPT, covering personal information protection, information verification, and avoiding excessive dependence, and conduct in-depth analysis of common misunderstandings by users, striving to provide a complete guide to use. In addition, this article will also discuss the possible security issues and the risk of malicious third-party abuse in the use of ChatGPT. It aims to help users fully realize their AI potential, while recognizing their limitations and guiding users to use it rationally. OpenAI Deep Research, the latest AI agent released by OpenAI. For details, please click ⬇️ Creative content production

10 Key Findings From AWS Generative AI Adoption IndexMay 16, 2025 am 05:07 AM

10 Key Findings From AWS Generative AI Adoption IndexMay 16, 2025 am 05:07 AMThis month's release of the index provides data-centric insights into the integration of generative AI within business operations. It draws on feedback from more than 3,739 IT decision-makers across nine countries, offering real-world data instead of

Is ChatGPT heavy because of time? Easy to understand explanations for each causeMay 16, 2025 am 05:06 AM

Is ChatGPT heavy because of time? Easy to understand explanations for each causeMay 16, 2025 am 05:06 AMChatGPT is an innovative AI-based chatbot, but it can sometimes run slower or unstable for various reasons. There are many reasons for the slow response speed of ChatGPT, such as network connection problems, server load, complex prompt words, excessive tasks running simultaneously, and errors. This article will clearly explain how to deal with these problems through practical cases. If you are experiencing slow responses in ChatGPT or want to leverage AI to improve productivity and daily tasks, please refer to this article. You will learn the skills to get the most out of AI performance. For details of the latest AI agent "OpenAI Deep Research" released by OpenAI, please click

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.

SublimeText3 English version

Recommended: Win version, supports code prompts!

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

Dreamweaver CS6

Visual web development tools