Technology peripherals

Technology peripherals AI

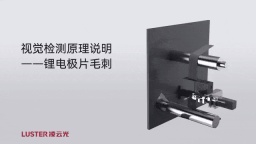

AI Machine Vision + AI | Lingyunguang's innovative solution overcomes the problem of lithium battery burr detection

Machine Vision + AI | Lingyunguang's innovative solution overcomes the problem of lithium battery burr detectionIn recent years, frequent fire accidents in the fields of electric vehicles and energy storage have triggered large-scale recalls, and the responsible parties have affected battery companies. At the same time, with the entire industry under heavy pressure of overcapacity and price wars intensifying, battery companies are increasingly demanding high-quality control and safety in the production process.

Pictures come from the Internet

Pictures come from the Internet

According to the IEEE1725 battery cell safety performance audit and testing standards, burrs are metal protrusions that extend upward or downward from the foil to the outside of the pole piece, taking the foil (i.e., the uncoated area) as the baseline. ; Or it is a coated area, a metal protrusion extending upward or downward from the coating to the direction outside the pole piece; measuring the burr size is to measure the height of the burr in the vertical direction.

The content that needs to be rewritten is: glitch diagram (note: the diagram comes from the Internet)

The content that needs to be rewritten is: glitch diagram (note: the diagram comes from the Internet)

Too large burrs can easily

pierce the diaphragm, causing the positive and negative electrodes to contact and cause a short circuit . If a short circuit occurs when the battery is fully charged, a large amount of heat will be immediately released inside, causing an explosion, seriously endangering the safety of consumers' lives and property. Although the burrs are small, the hidden dangers are huge

There are many demands and detection becomes difficultIn actual production, in order to make batteries of different sizes, the pole pieces after coating and rolling need to go through processes such as slitting and punching. Taking the slitting process as an example, the physical and mechanical properties of the pole piece itself, the amount of overlap of the paired tools, and the wear state of the cutting edge will all affect the generation and size of burrs. From the perspective of testing requirements, if we want to comprehensively control product quality, we must not only

detect whether there are burrs, but also make different judgmentsbased on the size of the burrs. From the perspective of detection methods, pole piece burr detection mostly uses visual microscopes for offline detection, but even using a large depth-of-field microscope still has problems with insufficient depth of field and insufficient magnification. At the same time, in order to complete the measurement function, multiple systems need to operate at the same time, which makes the operation cumbersome and increases the cost.

The burr detection process of battery companies has strict requirements on the existing detection solutions and cannot achieve the goal of efficient manufacturing

Innovative solution "Machine Vision Artificial Intelligence" to solve difficult problemsAs one of the earliest domestic companies to enter the field of machine vision, Lingyunguang has always adhered to the R&D concept of independent innovation, and has successively overcome many problems such as computational imaging and precision imaging, constantly transforming cutting-edge R&D results into productivity and also into Implemented solutions to solve customers’ actual problems. Faced with the problem of burr detection, Ling Yunguang launched a lithium battery burr online full inspection system and used "machine vision AI" solutions to solve industry problems.

Innovative optical solution: When pursuing speed and accuracy, we must take into account the balance between the two

In order to complete defect detection without affecting the overall production capacity, online full inspection is undoubtedly the best solution. To stably detect micron-level burr defects in high-speed production and high-vibration environments, factors such as space and investment must be comprehensively considered, which is very difficult.

In order to complete defect detection without affecting the overall production capacity, online full inspection is undoubtedly the best solution. To stably detect micron-level burr defects in high-speed production and high-vibration environments, factors such as space and investment must be comprehensively considered, which is very difficult.

High-speed imaging with high-speed cameras as the core can closely link the spatial and temporal information during high-speed motion changes for image recording, so it can effectively detect transient or high-speed motion situations. It can continuously record and quickly transmit signals to image processing equipment for corresponding operations. It has been widely used in industry, military, transportation, medicine and other fields.

Ling Yunguang has migrated and applied this technology to the field of pole piece burr detection. At the same time, combined with

's self-developed optical system, it realizes adaptive focusing, improves the system's depth of field, and achieves high-resolution, large field of view, and large depth of field high-speed imaging, achieving 150m/min speed Stable and clear imaging, complete inspection of pole piece edge burrs,

detection resolution 2μm.Adaptive focus animation demonstration

In addition, we can also complete high-precision full inspection offline with a resolution of 1μm during the process quality inspection process such as quality analysis and process traceability of the pole pieces.

F.Brain is a deep learning platform independently developed by Lingyunguang for industrial quality inspection scenarios, and has been widely used in the field of lithium battery testing. In the burr detection scenario, defects are first screened and classified by traditional algorithms, and the detected defects are segmented and then sent to the classification algorithm. For high-speed and low-cost scenarios, F.Brain has developed a self-developed multi-scale lightweight model, which reduces inference time by 35% compared to general models on the market. The detection speed can reach 150m/min, and the false alarm rate is less than one in 100,000, meeting the strict requirements of customers.

Software interoperability: seamless connection

For battery companies, detecting and handling defects is only the first step. Full production line management and full process management are the development direction to further improve product quality and ensure product safety.

The burr online full inspection system also has functions such as labeling linkage, alarm and anti-fooling, and can be linked with the company's own MES to interact with data centers and terminal storage to meet The retention period of enterprise defect information is required to achieve data traceability and traceability.

In the face of new changes and new demands in the lithium battery industry in the future, Lingyunguang will maintain its technical foundation, deeply explore customer needs, and use innovative products and solutions to help customers demand quality in every detail and in every link. Strict management to achieve the goal of zero complaints!

The above is the detailed content of Machine Vision + AI | Lingyunguang's innovative solution overcomes the problem of lithium battery burr detection. For more information, please follow other related articles on the PHP Chinese website!

What is Model Context Protocol (MCP)?Mar 03, 2025 pm 07:09 PM

What is Model Context Protocol (MCP)?Mar 03, 2025 pm 07:09 PMThe Model Context Protocol (MCP): A Universal Connector for AI and Data We're all familiar with AI's role in daily coding. Replit, GitHub Copilot, Black Box AI, and Cursor IDE are just a few examples of how AI streamlines our workflows. But imagine

Building a Local Vision Agent using OmniParser V2 and OmniToolMar 03, 2025 pm 07:08 PM

Building a Local Vision Agent using OmniParser V2 and OmniToolMar 03, 2025 pm 07:08 PMMicrosoft's OmniParser V2 and OmniTool: Revolutionizing GUI Automation with AI Imagine AI that not only understands but also interacts with your Windows 11 interface like a seasoned professional. Microsoft's OmniParser V2 and OmniTool make this a re

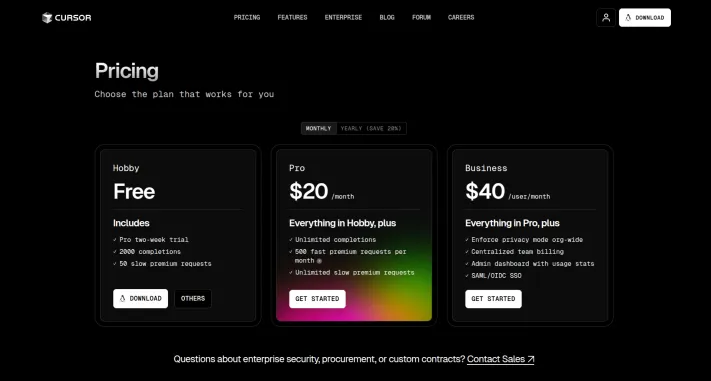

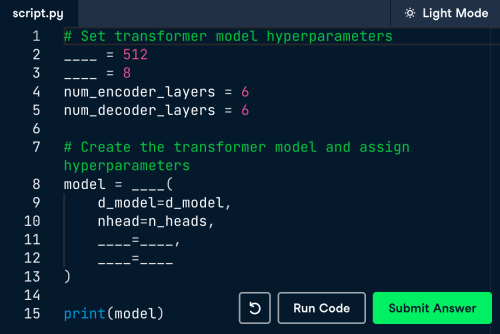

I Tried Vibe Coding with Cursor AI and It's Amazing!Mar 20, 2025 pm 03:34 PM

I Tried Vibe Coding with Cursor AI and It's Amazing!Mar 20, 2025 pm 03:34 PMVibe coding is reshaping the world of software development by letting us create applications using natural language instead of endless lines of code. Inspired by visionaries like Andrej Karpathy, this innovative approach lets dev

Replit Agent: A Guide With Practical ExamplesMar 04, 2025 am 10:52 AM

Replit Agent: A Guide With Practical ExamplesMar 04, 2025 am 10:52 AMRevolutionizing App Development: A Deep Dive into Replit Agent Tired of wrestling with complex development environments and obscure configuration files? Replit Agent aims to simplify the process of transforming ideas into functional apps. This AI-p

Runway Act-One Guide: I Filmed Myself to Test ItMar 03, 2025 am 09:42 AM

Runway Act-One Guide: I Filmed Myself to Test ItMar 03, 2025 am 09:42 AMThis blog post shares my experience testing Runway ML's new Act-One animation tool, covering both its web interface and Python API. While promising, my results were less impressive than expected. Want to explore Generative AI? Learn to use LLMs in P

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!Mar 22, 2025 am 10:58 AM

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!Mar 22, 2025 am 10:58 AMFebruary 2025 has been yet another game-changing month for generative AI, bringing us some of the most anticipated model upgrades and groundbreaking new features. From xAI’s Grok 3 and Anthropic’s Claude 3.7 Sonnet, to OpenAI’s G

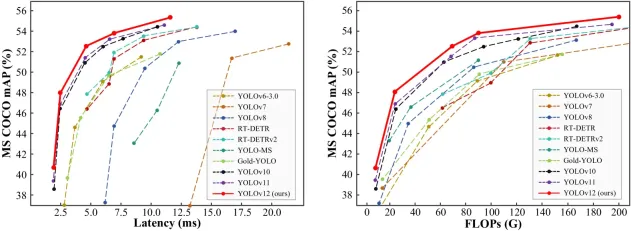

How to Use YOLO v12 for Object Detection?Mar 22, 2025 am 11:07 AM

How to Use YOLO v12 for Object Detection?Mar 22, 2025 am 11:07 AMYOLO (You Only Look Once) has been a leading real-time object detection framework, with each iteration improving upon the previous versions. The latest version YOLO v12 introduces advancements that significantly enhance accuracy

Elon Musk & Sam Altman Clash over $500 Billion Stargate ProjectMar 08, 2025 am 11:15 AM

Elon Musk & Sam Altman Clash over $500 Billion Stargate ProjectMar 08, 2025 am 11:15 AMThe $500 billion Stargate AI project, backed by tech giants like OpenAI, SoftBank, Oracle, and Nvidia, and supported by the U.S. government, aims to solidify American AI leadership. This ambitious undertaking promises a future shaped by AI advanceme

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Dreamweaver CS6

Visual web development tools

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool