Home >Technology peripherals >AI >AI allows products to better understand consumers and injects momentum into Lenovo's second curve

AI allows products to better understand consumers and injects momentum into Lenovo's second curve

- WBOYforward

- 2023-05-25 19:57:001595browse

Artificial intelligence is coming. Today, product design and manufacturing are becoming more understanding of people's needs and consumer needs. Because people may not be on site, but the supply chain and production can "change according to people."

Lenovo Group has always been praised by the outside world as a pioneer in innovation in China's manufacturing industry and is committed to building a smart supply chain. With its leading supply chain capabilities that combine globalization, intelligence, and hybrid manufacturing models, Lenovo Group has been selected for the eighth time by Gartner, a well-known data research institution, among the top 25 global supply chains in 2022, ranking ninth.

Gartner's top 25 global supply chains in 2022, Lenovo Group ranks ninth

The so-called smart supply chain refers to the use of intelligent platforms to calculate, think, and make decisions, and to use digital operation platforms to quantify supplier supply volume, reasonable supply prices, warehousing volume, warehousing locations, user preferences, etc. Produce accurate predictions to guide business operations and automated operations such as warehousing and transportation.

Not only that, according to the target of decision-making, the smart supply chain can also establish calculation models, use AI to deeply mine and analyze relevant data, and guide the operation of the entire industry chain.

After self-learning, these supply chain AI systems can also predict future supply chain problems, proactively make decisions, and autonomously implement corresponding solutions to further enhance customer experience.

The mobile business is one of the core businesses of Lenovo Group. Now, Lenovo's Mobile Device Supply Chain (MDSC) department uses intelligent operations, digital transformation and customer experience improvement as a booster to achieve smart supply chain. When we talk about supply chains, especially in the age of artificial intelligence, we are not limited to talking about the production of items and the distribution of goods, but also need to consider the human experience.

01 Behind the popular folding mobile phone: the introduction of new products into the digital system with the ability to think

The smartphone industry chain can be said to be the benchmark for manufacturing in China. From new product manufacturing to brand building, Chinese manufacturers are fighting fiercely. Brands can create unique effects in any area where creativity can be exerted, from configuration to appearance to user experience.

Folding screen smartphones are a typical case. In the past few years, foldable screen mobile phones have emerged from scratch and have now become a high-profile new darling in the mobile phone market. The quarterly mobile phone tracking report released by market research company IDC shows that in the first quarter of 2023, China’s folding screen product shipments remained stable, with a year-on-year growth of 52.8%.

However, the durability and reliability of foldable screen mobile phones are also questions in the minds of many consumers. To strike a balance between satisfying the ever-changing "freshness" of consumers and ensuring the "reliability" of the product, Lenovo's Motorola Moto Razr has achieved it.

Moto Razr

Motorola is the oldest brand to launch folding screen mobile phones. It can be said that it pioneered the journey of flexible screen technology. For example, the "water drop hinge" technology that is almost used in the field of folding screen mobile phones today is an upgrade from Moto's early technology to some extent.

Motorola’s Moto Razr can not only achieve a folding effect, but also has extremely high durability and stability, and can also ensure the continuous launch of new products every year. The intelligent new product introduction management system behind this is Intelligent New Product Introduction (referred to as i-NPI) has contributed a lot.

New product introduction (NPI) is different from mass production. Various special needs of the market, product development maturity, supplier segment stability, factory production line capabilities and many other constraints make new product introduction management very difficult. Complex, and these tasks often needed to be done manually.

In this process, a large amount of data will also be generated. How to use this data to help business improve efficiency, reduce design and R&D costs, cope with the changing market, and better meet customer needs, there is an urgent need for a complete and comprehensive digital solution. Program provides support.

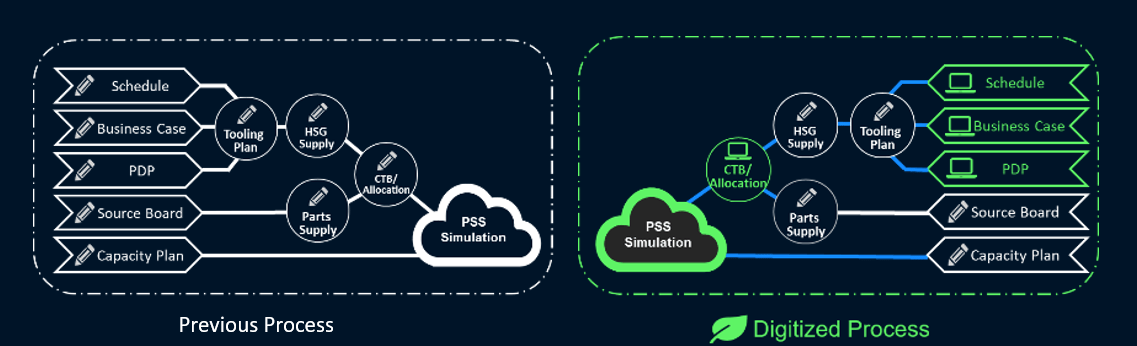

Before and after comparison of intelligent production and shipping planning algorithm

In this context, Lenovo Mobile Device Supply Chain (MDSC) defined and built i-NPI (Platform). This "one platform", "one portal" and "full link service" MDSC NPI business ecosystem covers the business models and processes that NPI is mainly responsible for, including Project Shippable Supply (PSS), shell supply, The NPI multi-dimensional project management system integrates big data summary and analysis reports, process management and other functions. It also uses new business/data application models to support horizontal business collaboration and vertical management and control. Data analysis moves from point-like demand support to data self-service analysis. Model transformation to achieve scientific operations and intelligent innovation.

On this basis, MDSC can transfer the management of the entire supply chain new product introduction process from offline to online, achieving end-to-end visualization, transparency, and traceability of data and processes, effectively avoiding The emergence of data islands. In addition, smart tools can transform complex work from manual to automatic and provide intelligent decision-making, greatly improving efficiency and shortening the product introduction cycle by 21 days.

02 High-quality delivery: Let products and consumers have a positive “interaction”

New product research and development is only the first step. After a new mobile phone product is put on the market, intelligent data analysis of supply chain quality can not only improve the level of after-sales service and guide the production process, but also promote consumer feedback and the relationship between the product and the product. positive interaction.

For example, when a mobile phone has quality problems that affect the customer's use, the customer usually repairs or replaces it at the after-sales service, and the after-sales service system will automatically upload the record of the faulty machine to the system. Combining the activation record and repair record of the mobile phone, the system can calculate the after-sales return rate of the model from the activation to the present, thereby predicting the after-sales return situation for a complete year to guide the design improvement of mobile phone products.

After-sales hot issues, any delay for one second will be harmful to the brand. In order to provide users with a better experience, the speed and efficiency of product improvement are particularly important. Lenovo Mobile Device Supply Chain (MDSC) has developed two analytical prediction models to improve the level of supply chain quality management and improve user experience.

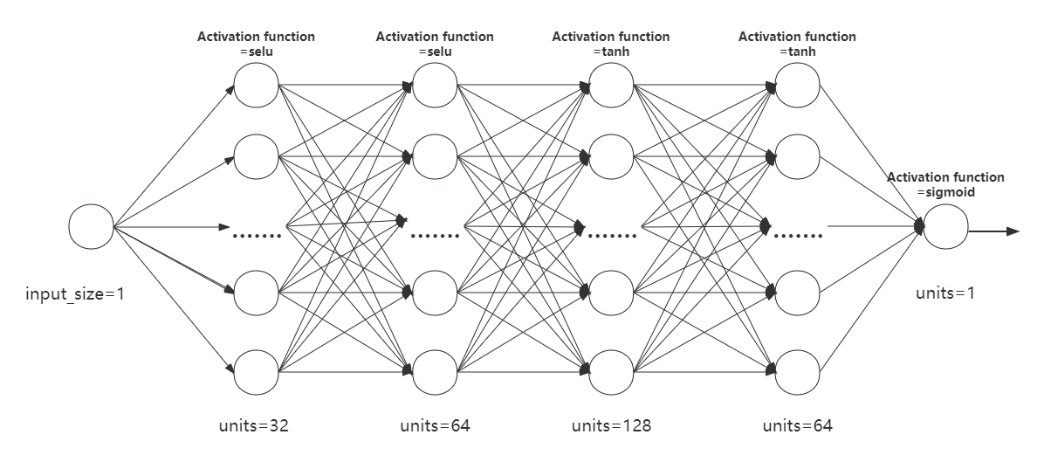

Neural Network Structure Diagram

The first model is the Early Insight Warranty (EIW) data model.. It is a prediction model for product after-sales repair rate based on machine learning regression analysis.

Specifically, predictions based on activation data and repair data can not only optimize the R&D and manufacturing processes, reduce costs, and improve product quality and reliability, but also predict future maintenance needs and maintenance costs, and then formulate corresponding maintenance plans. Strategies to arrange and plan after-sales service spare parts in advance to improve maintenance efficiency and service quality.

In addition, the EIW model can also guide risk management, allowing relevant parties to make quality management decisions as early as possible, introduce corresponding measures, avoid risks early, and improve user satisfaction.

ODF working principle diagram

The second set of On-Device Feedback (ODF) model is a user feedback analysis tool developed based on NLP (natural language processing) technology. The model can automatically identify and classify customer feedback information and transform it into structured data. This data can be used to analyze and monitor changes and trends in product quality and customer experience.

This model can help the customer's quality management team quickly discover after-sales quality problems and take immediate action to improve them. It is worth mentioning that the tags table in the model is compiled based on years of business accumulation. It can not only classify quality issues and support continuous updates, but its work efficiency is even more amazing. Originally, about 100 items were analyzed manually. / hour, while ODF automatic analysis can reach about 2,000 items / hour, increasing the efficiency by 20 times.

With the EIW prediction model and ODF analysis model, as well as more intelligent data application scenarios behind them, the data generated in each link of the supply chain is no longer just a cold "indicator", but also a "guideline" to serve customers ".

Overall, MDSC maintains a high level of production efficiency and supply chain operation capabilities through the intelligent use of quality data and interconnected digital systems. In the face of changing market environments and various challenges, MDSC can stabilize and Deliver high-quality products efficiently and respond quickly to customer needs to help improve customer experience.

03 Lenovo mobile device supply chain: supporting Lenovo’s second curve

Whether it is the creation of the i-NPI system or the application of the EIW and ODF models, it is all carried out with the support of the key strategies of the mobile device supply chain (MDSC) that are oriented towards resilience, efficiency and customer experience. Despite the unprecedented challenges of the epidemic, Lenovo has been able to maintain high-quality delivery performance.

With the support of Lenovo’s global supply chain, including the MDSC department, during the epidemic, Lenovo Group not only did not experience large-scale production and work shutdowns, but instead seized growth opportunities. In fiscal year 2021/22, while the year-on-year growth rate of mobile phone business revenue for the full fiscal year was 30 percentage points higher than the market, operating profit reached 2.3 billion yuan, a year-on-year increase of 110%, creating the highest since the Motorola merger; Android tablets year-on-year Growth of 20.2%, maintaining the second place in the Android market globally.

In the 2022/23 fiscal year, despite the overall decline in market conditions, Lenovo’s mobile phone business still maintains the top three market rankings in the Latin American market, and its tablet products also maintain the top three results in the Android market, successfully helping Lenovo Group to build a second growth curve.

Lenovo’s mobile business is also full of surprises in terms of product innovation. Data from the latest quarterly financial report (the third quarter of fiscal year 2022/23) show that the smartphone business has remained profitable for 11 consecutive quarters, and the activation volume of the high-end product Motorola Edge has increased by 74% year-on-year. Lenovo ThinkPhone by Motorola, Lenovo's first mobile phone designed specifically for business scenarios, has won 15 "Best of CES" awards for its strong positioning in safety and productivity.

"Best of CES" Award

Lenovo ThinkPhone, Lenovo’s first mobile phone designed specifically for commercial scenarios

Yang Yuanqing said at the Lenovo Group Cloud Swearing Conference three years ago that this is a critical moment for Lenovo Group to turn around. Today, Yang Yuanqing announced Lenovo Group’s “five major goals” for the new fiscal year at the 2023/24 fiscal year swearing-in meeting. Among them, the Mobile Business Group (MBG) revenue has achieved a 15% year-on-year growth, and the business has grown to a scale of US$8 billion.

Zhang Wei, head of Lenovo's mobile device supply chain, revealed that the company is taking "efficiency, growth, and resilience" as strategic pillars, based on "continuous digital transformation" and always focusing on "serving customers" to create a "full The competitive advantages of the “stack” supply chain. To ensure business continuity and organic business growth, and help achieve mobile device business goals.

The above is the detailed content of AI allows products to better understand consumers and injects momentum into Lenovo's second curve. For more information, please follow other related articles on the PHP Chinese website!

Related articles

See more- When GPT-4 learns to read pictures and texts, a productivity revolution is unstoppable

- To fight ChatGPT, Google launches Bard beta version

- What improvement does GPT-4 have over ChatGPT? Jen-Hsun Huang held a 'fireside chat' with OpenAI co-founder

- ChatGPT vs. GPT-3 vs. GPT-4 is just an internal fight among chatbot families

- Seven tips and tricks for applying robotics