Is the construction industry ready to deploy robots?

Robots are increasingly being deployed on construction sites around the world, with applications ranging from automated bricklaying to 3D printing to site surveying. These robots have proven their ability to perform tasks faster and more accurately than human workers. However, there are still some challenges that need to be overcome, such as high investment costs, the need to re-engineer workflows and resistance to change, Harsh Pareek, Regional Sales Director, India and SAARC, Trimble Solutions, shared his application of AI in the construction industry.

As megatrends such as inflation, geopolitical uncertainty, ecological constraints and the need to house more people faster combine to challenge the industry, the potential benefits of building automation appear greater than ever All greater and undeniable.

In an industry that prioritizes increasing productivity and improving worker safety, the use of robots and automated construction equipment seems like a natural fit. Robots have been part of the global $12 trillion construction industry for some time, and their applications are diverse.

From fully automated bricklaying and 3D printing to site surveying, these construction robots have proven their ability to perform a range of tasks faster and more accurately than human workers.

In 2018, Australian robotics company FBR’s autonomous bricklaying robot built a three-bedroom house in less than three days. An early version of this fully autonomous robot can place up to 200 blocks per hour, which is roughly equivalent to 2,000 bricks. It can do work in 48 hours that would take human workers four to six weeks. The latest version is said to be even faster - it can complete the interior and exterior walls of a standard double-storey brick house in a day.

Robots Targeting Project Sites

These and many other robotic innovations are increasingly being deployed on construction sites around the world. A 2019 survey by consultancy KPMG found that among the top 20% of construction firms that consider themselves “technology ready”, 86% use building information modeling (BIM), 72% use drones and 10% use construction robot.

Another post-pandemic survey of nearly 2,000 small and large construction and related businesses in Europe, North America and China was even more revealing – 81% of respondents were certain they would introduce robots within the next decade .

The market opportunity for construction robots is huge enough to attract interest from companies and startups around the world. In September 2022, technology giant HP launched an on-site printing robot that can automatically print the layout of digital models on the floor of a construction site. The machine can outline walls, doors and other elements with little to no intervention. Other startups, such as Dusty Robotics and Rugged Robotics, have launched similar robots that can automate building layouts.

The fusion of advanced technologies such as computer vision and artificial intelligence (AI) allows robots to complete more complex and complex tasks without human supervision for the first time.

The timing couldn't be better - the global construction industry has been facing labor shortages since the start of the pandemic, and they are further squeezed by rising inflation and rapidly rising input costs due to the Ukraine-Russia conflict profit margin.

Digitalization is driving greater adoption of robotics

The construction industry lags behind its peers in technology adoption. This may explain why annual productivity growth in the construction industry has averaged just 1% over the past 20 years, according to research from McKinsey. In manufacturing, where robots are already the mainstay of the shop floor, annual productivity growth during the same period was 3.6%.

Still, whether the construction industry is ready to actively embrace and use robots remains an open question. First, investing in full automation can be expensive, and for many construction companies, allocating resources to robots while dealing with declining margins and profitability can be challenging. Second, adopting robots isn’t as simple as plug-and-play—construction companies may have to completely reimagine or redesign their workflows to take full advantage of robots.

For an industry that has relied on paper models and manual guidance for centuries, such a dramatic reinvention of automated processes can be daunting. Fortunately, there is strong motivation to pursue this path. McKinsey Global Institute estimates that productivity in some parts of the construction industry could increase by 5-10 times by moving to manufacturing-based production systems.

The global pandemic has proven to be another powerful driver of accelerated digitalization in the construction industry, prompting some large and advanced contractors to turn to BIM and cloud-based collaboration tools for more efficient remote project management.

Once core processes are digitized, deploying robots to automate them is relatively simple. For example, once a detailed 3D BIM model of a structure is ready, it can be used to program robots to perform multiple downstream tasks – from bricklaying to 3D printing of building modules.

Robots are ready to build homes

Several companies are focusing on using robots for 3D printing to help complete construction projects faster. US-based ICON used its autonomous construction robot to 3D print an entire house in 24 hours for $10,000. The Austrian company Printstones recently launched a multifunctional construction robot that is capable of more than just 3D concrete printing. It can carry out material transport, welding, milling, screw drives, plasma cutting, spray painting, and even bricklaying.

In fact, using robots to 3D print building structures is a huge opportunity in itself. For example, Dubai has set a goal that 25% of new buildings will use 3D printing technology by 2030. The United States and China are the other two major economies promoting the use of 3D printing technology in construction. Furthermore, with rapid urbanization, the demand for housing and urban infrastructure will only increase in the coming years.

A disruptive shift is coming

Ultimately, there is a clear business case for investing in and deploying robots across all construction activities. The promise of significantly faster construction at lower costs, greater accuracy and safety, and fewer errors or waste is a powerful enough incentive. Additionally, ongoing robotics research and development efforts are expected to reduce the cost of automation, making robots accessible to the vast majority of construction companies.

The turning point in the deployment of robots in the construction industry is coming. It also promises to enable the most disruptive shift in the way the industry operates since the early days of the Industrial Revolution.

The above is the detailed content of Is the construction industry ready to deploy robots?. For more information, please follow other related articles on the PHP Chinese website!

The Hidden Dangers Of AI Internal Deployment: Governance Gaps And Catastrophic RisksApr 28, 2025 am 11:12 AM

The Hidden Dangers Of AI Internal Deployment: Governance Gaps And Catastrophic RisksApr 28, 2025 am 11:12 AMThe unchecked internal deployment of advanced AI systems poses significant risks, according to a new report from Apollo Research. This lack of oversight, prevalent among major AI firms, allows for potential catastrophic outcomes, ranging from uncont

Building The AI PolygraphApr 28, 2025 am 11:11 AM

Building The AI PolygraphApr 28, 2025 am 11:11 AMTraditional lie detectors are outdated. Relying on the pointer connected by the wristband, a lie detector that prints out the subject's vital signs and physical reactions is not accurate in identifying lies. This is why lie detection results are not usually adopted by the court, although it has led to many innocent people being jailed. In contrast, artificial intelligence is a powerful data engine, and its working principle is to observe all aspects. This means that scientists can apply artificial intelligence to applications seeking truth through a variety of ways. One approach is to analyze the vital sign responses of the person being interrogated like a lie detector, but with a more detailed and precise comparative analysis. Another approach is to use linguistic markup to analyze what people actually say and use logic and reasoning. As the saying goes, one lie breeds another lie, and eventually

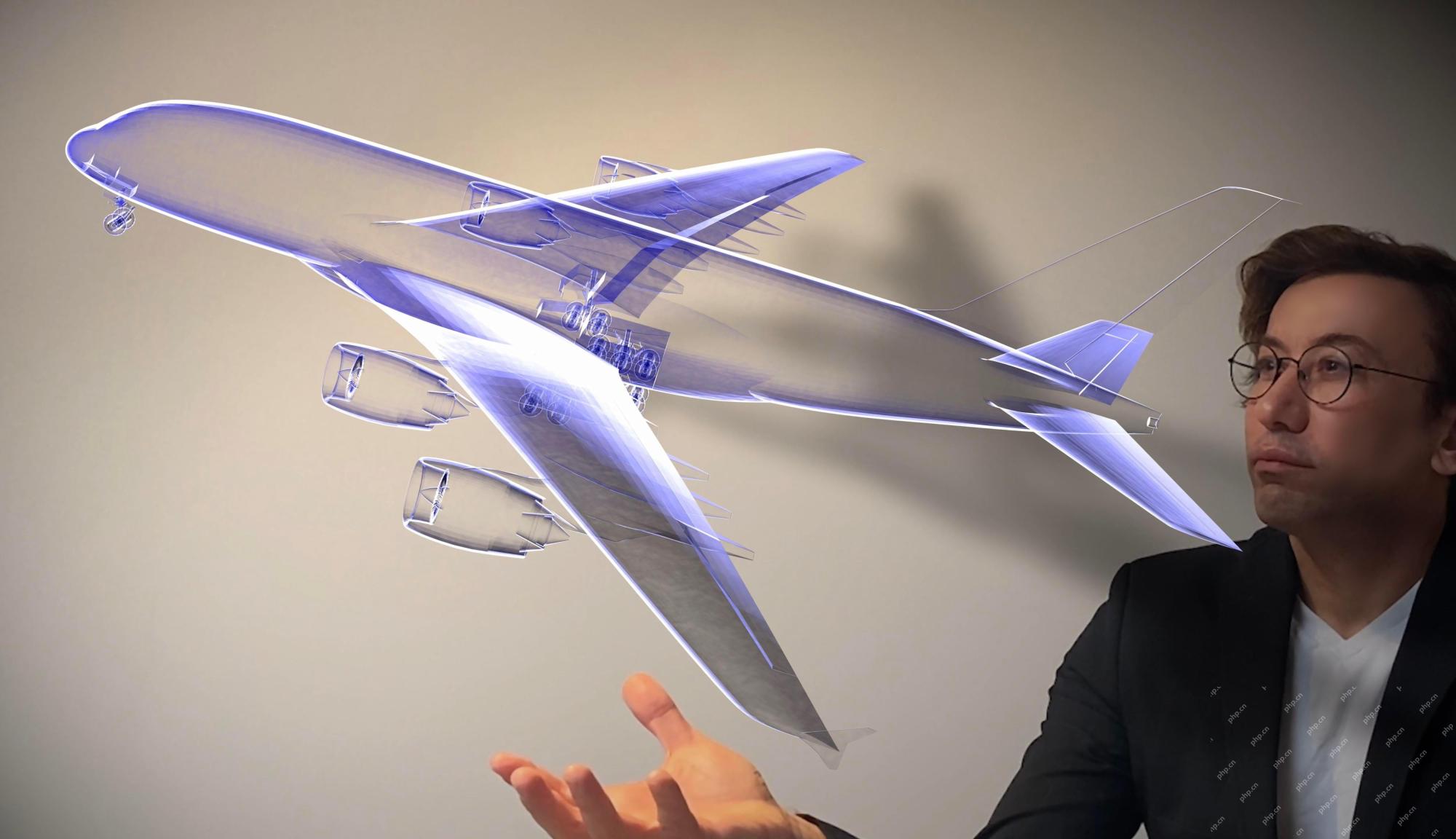

Is AI Cleared For Takeoff In The Aerospace Industry?Apr 28, 2025 am 11:10 AM

Is AI Cleared For Takeoff In The Aerospace Industry?Apr 28, 2025 am 11:10 AMThe aerospace industry, a pioneer of innovation, is leveraging AI to tackle its most intricate challenges. Modern aviation's increasing complexity necessitates AI's automation and real-time intelligence capabilities for enhanced safety, reduced oper

Watching Beijing's Spring Robot RaceApr 28, 2025 am 11:09 AM

Watching Beijing's Spring Robot RaceApr 28, 2025 am 11:09 AMThe rapid development of robotics has brought us a fascinating case study. The N2 robot from Noetix weighs over 40 pounds and is 3 feet tall and is said to be able to backflip. Unitree's G1 robot weighs about twice the size of the N2 and is about 4 feet tall. There are also many smaller humanoid robots participating in the competition, and there is even a robot that is driven forward by a fan. Data interpretation The half marathon attracted more than 12,000 spectators, but only 21 humanoid robots participated. Although the government pointed out that the participating robots conducted "intensive training" before the competition, not all robots completed the entire competition. Champion - Tiangong Ult developed by Beijing Humanoid Robot Innovation Center

The Mirror Trap: AI Ethics And The Collapse Of Human ImaginationApr 28, 2025 am 11:08 AM

The Mirror Trap: AI Ethics And The Collapse Of Human ImaginationApr 28, 2025 am 11:08 AMArtificial intelligence, in its current form, isn't truly intelligent; it's adept at mimicking and refining existing data. We're not creating artificial intelligence, but rather artificial inference—machines that process information, while humans su

New Google Leak Reveals Handy Google Photos Feature UpdateApr 28, 2025 am 11:07 AM

New Google Leak Reveals Handy Google Photos Feature UpdateApr 28, 2025 am 11:07 AMA report found that an updated interface was hidden in the code for Google Photos Android version 7.26, and each time you view a photo, a row of newly detected face thumbnails are displayed at the bottom of the screen. The new facial thumbnails are missing name tags, so I suspect you need to click on them individually to see more information about each detected person. For now, this feature provides no information other than those people that Google Photos has found in your images. This feature is not available yet, so we don't know how Google will use it accurately. Google can use thumbnails to speed up finding more photos of selected people, or may be used for other purposes, such as selecting the individual to edit. Let's wait and see. As for now

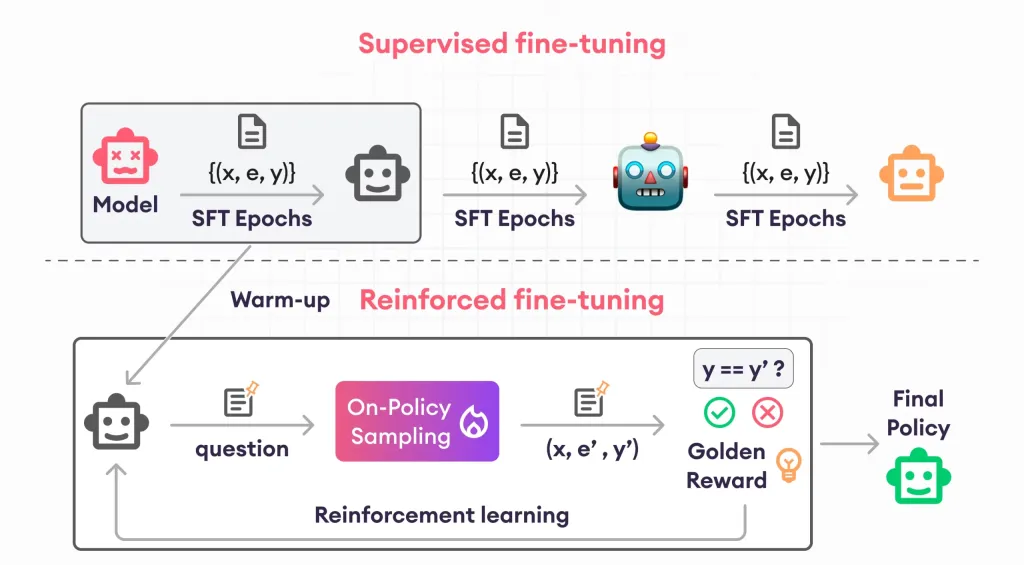

Guide to Reinforcement Finetuning - Analytics VidhyaApr 28, 2025 am 09:30 AM

Guide to Reinforcement Finetuning - Analytics VidhyaApr 28, 2025 am 09:30 AMReinforcement finetuning has shaken up AI development by teaching models to adjust based on human feedback. It blends supervised learning foundations with reward-based updates to make them safer, more accurate, and genuinely help

Let's Dance: Structured Movement To Fine-Tune Our Human Neural NetsApr 27, 2025 am 11:09 AM

Let's Dance: Structured Movement To Fine-Tune Our Human Neural NetsApr 27, 2025 am 11:09 AMScientists have extensively studied human and simpler neural networks (like those in C. elegans) to understand their functionality. However, a crucial question arises: how do we adapt our own neural networks to work effectively alongside novel AI s

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

SublimeText3 Chinese version

Chinese version, very easy to use

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.