In many parts of Asia, seasonal heavy rains bring flooding, destroying citizens’ property and livelihoods. In the past, city administrations, citizens and businesses could do little but protect against flooding and the potential illnesses it brought. And technologies such as the Internet of Things (IoT), machine learning (ML) and artificial intelligence (AI) may provide breathing room for more forward-thinking leaders.

This is the application of DKI Jakarta Provincial Government Flood Control System in Jakarta Smart City. The project was developed by Jakarta Smart City in partnership with the Jakarta Water Services Agency (DSDA) and aims to optimize flood risk management in Jakarta. The project involves using IoT, artificial intelligence and machine learning as part of an early warning system to combat flooding risks in cities.

As more organizations deploy the Internet of Things in commercial and industrial settings, the volume of data coming from these devices and sensors may have a significant impact on improving quality, operational efficiency, and in Jakarta It is of great significance to save lives and property from natural disasters.

The speed and accuracy with which IoT systems can respond to their environment is critical, according to Kenneth Koh, director of industry consulting at SAS Institute. However, because devices and other sensors in typical systems generate large amounts of data, traditional tools and methods can slow down the process of making sense of this data.

What is Artificial Intelligence Embedded Internet of Things?

Kenneth Koh: Processing data at or near the edge can make IoT systems more flexible and impactful. However, the quality of data-led actions is as meaningful as the quality of the data-based insights on which it is based.

The Internet of Things itself is not new to manufacturers. Manufacturers have been collecting and storing sensor data from machines for decades. Their value proposition lies in AIoT – analyzing data in real time at the edge, leveraging artificial intelligence and machine learning to increase efficiency and value.

By equipping IoT systems with artificial intelligence capabilities, a variety of structured and unstructured data can be processed at the edge. Deliver high-quality insights faster for systems to act on.

How Artificial Intelligence Embedded IoT Unlocks Business Value

Kenneth Koh: Artificial Intelligence Embedded IoT improves operational efficiency and productivity, At the same time, the cost is reduced. It also drives innovation to provide better customer service, better products and faster time to market.

Embedding AI in IoT devices enables edge computing, allowing the deployment of IoT systems where consistent 5G networks are unavailable. For example, logistics providers can use IoT sensors in their transport fleets to monitor the internal and external conditions of vehicles, even in remote areas of the latter routes.

In addition to edge computing, AI-embedded IoT leverages machine learning to develop actionable insights from the terabytes of data generated by IoT systems every day. In the example above, data collected from these sensors is sent to the cloud in real time, allowing technicians to troubleshoot vehicle problems more accurately and faster.

Manufacturers can also use these insights to predict when a specific factory system or piece of equipment will fail, allowing technicians to implement preventive maintenance. Proactively detecting faulty equipment saves valuable man-hours while reducing costly unplanned downtime.

In retail, insights from IoT systems can be used to determine the optimal price for a product and minimize disruption to its supply chain.

The role of machine learning in IoT analysis

Kenneth Koh: Machine learning is artificial intelligence embedded in IoT compared to other IoT Deployment advantages. The system can learn while processing the data generated by the sensors, using a variety of advanced analysis methods such as decision trees, random forests, gradient boosting, neural networks, support vector machines and factorization machines.

This saves businesses human time and experts in the organization. Without the need to train AI systems extensively, experts can focus on other critical tasks while non-data scientists can access, view and process the data.

Machine learning capabilities also increase the range of data that AI systems can access and process: visual images, text and even spoken speech, both online and offline. The increase in the quantity and quality of existing data increases the value and impact of the insights gained from it.

Combining these machine learning capabilities increases the speed and volume of data processing, enabling real-time actionable insights. This is crucial in many IoT systems.

How AIoT supports Jakarta Smart City: Leveraging SAS’s artificial intelligence platform, Jakarta Smart City is able to integrate multi-source data in real time and provide advanced analytics through IoT, machine learning and artificial intelligence technologies to provide emergency/disaster prediction capabilities and Optimize services to the public. The result is a flood emergency response that reduces flood risk in Jakarta.

Given that IoT is historically an operational technology, who should own IoT security?

Kenneth Koh: The introduction of IoT is ambiguous blur the line between enterprise IT and OT. Sensors and devices are connected to the network to create new systems and improve processes. At the same time, this convergence exposes traditional OT equipment and systems to threats they never faced before.

In fact, true device security is a combination of technology, process and best practices. Therefore, securing IoT systems should not be the exclusive domain of OT or IT teams, but should result in closer and more effective collaboration between the two.

However, this is easier said than done because IT security teams and OT security teams often don’t speak the same language, making it difficult to understand each other’s perspectives.

The distribution of responsibilities is completely different. Priorities often diverge, and regulations governing OT security and IT security are sometimes conflicting. Gaining an overview of all assets in a given environment makes it clear which assets and processes cannot fail under any circumstances.

By doing this, organizations can establish and practice unified cybersecurity to ensure data confidentiality, integrity, and availability.

Cite a best practice for IT and operations technicians to work together

Kenneth Koh: In manufacturing, data versus time Very sensitive. For example, if chemical concentrations in a process deviate from optimal concentrations, engineers may only have minutes to react to save tons of product.

In many semiconductor processes, engineers only have seconds to react. In this case, analytics needs to move to the “edge,” meaning data must be analyzed and decisions made on the machine or on the shop floor, rather than in the back office or engineering department.

This requires the ability to perform analytics wherever needed, such as on the machine, on the production floor, in the cloud or in the back office.

One of the main challenges is data silos. For organizations that have not implemented IT/OT convergence, there is a patchwork of unintegrated or partially integrated applications and enterprise systems. Without careful planning, introducing new data sources, such as IoT sensors, can compound the problem.

Implementing a data integration platform to connect IoT systems with an organization’s existing technology stack can break down silos between historical and future data while providing a single point of control Give all teams the same access. This ensures that IT and OT teams are on the same page, laying the foundation for better IT/OT integration.

The above is the detailed content of The value of artificial intelligence in IoT analytics. For more information, please follow other related articles on the PHP Chinese website!

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AM

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AMRunning large language models at home with ease: LM Studio User Guide In recent years, advances in software and hardware have made it possible to run large language models (LLMs) on personal computers. LM Studio is an excellent tool to make this process easy and convenient. This article will dive into how to run LLM locally using LM Studio, covering key steps, potential challenges, and the benefits of having LLM locally. Whether you are a tech enthusiast or are curious about the latest AI technologies, this guide will provide valuable insights and practical tips. Let's get started! Overview Understand the basic requirements for running LLM locally. Set up LM Studi on your computer

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AM

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AMGuy Peri is McCormick’s Chief Information and Digital Officer. Though only seven months into his role, Peri is rapidly advancing a comprehensive transformation of the company’s digital capabilities. His career-long focus on data and analytics informs

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AM

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AMIntroduction Artificial intelligence (AI) is evolving to understand not just words, but also emotions, responding with a human touch. This sophisticated interaction is crucial in the rapidly advancing field of AI and natural language processing. Th

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AM

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AMIntroduction In today's data-centric world, leveraging advanced AI technologies is crucial for businesses seeking a competitive edge and enhanced efficiency. A range of powerful tools empowers data scientists, analysts, and developers to build, depl

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AM

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AMThis week's AI landscape exploded with groundbreaking releases from industry giants like OpenAI, Mistral AI, NVIDIA, DeepSeek, and Hugging Face. These new models promise increased power, affordability, and accessibility, fueled by advancements in tr

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AM

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AMBut the company’s Android app, which offers not only search capabilities but also acts as an AI assistant, is riddled with a host of security issues that could expose its users to data theft, account takeovers and impersonation attacks from malicious

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AM

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AMYou can look at what’s happening in conferences and at trade shows. You can ask engineers what they’re doing, or consult with a CEO. Everywhere you look, things are changing at breakneck speed. Engineers, and Non-Engineers What’s the difference be

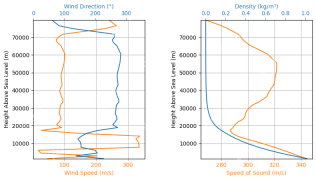

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AM

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AMSimulate Rocket Launches with RocketPy: A Comprehensive Guide This article guides you through simulating high-power rocket launches using RocketPy, a powerful Python library. We'll cover everything from defining rocket components to analyzing simula

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

WebStorm Mac version

Useful JavaScript development tools

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.