Technology peripherals

Technology peripherals AI

AI See you soon! You can make a robot by picking up a few branches... It can walk and grasp, and it can also be used in medical rehabilitation in the future.

See you soon! You can make a robot by picking up a few branches... It can walk and grasp, and it can also be used in medical rehabilitation in the future.If you were asked to make a robot using the things you have on hand, what would you think of?

Can branches work? No problem at all.

A doctorate guy from Beautiful Country randomly picked up a few branches and made a robot that can walk and grasp. Maybe this is Ke(shou) ) Let’s learn the highest realm of (yi) family (ren).

This robot is called StickBot as its name suggests. It looks really rough. Who would have thought that it can control movement through an APP!

In addition to branches, it consists of circuits, actuators, microcontrollers and motor drivers. There are two modes: In "crawl mode", branches It’s the robot’s legs, which can rotate and crawl forward:

In the “grasp mode”, the branches become With the arm attached, the rocker is connected to the controller plate on one side to form a hinged joint, while moving through its free end to firmly grip the cup, it automatically releases the arm when it senses someone is about to remove the cup. .

The designer of this robot is Devin Carroll, a doctoral student at the University of Pennsylvania. According to him, “This is a A modular robot where you can put a bunch of branches into various structures with different configurations."

This person The little brother’s whimsical ideas don’t stop there. In addition to the branch robot, he also made a robot IceBot made entirely of ice, which also won the Guinness World Record in 2020.

With a rectangular body and two large wheels, IceBot looks like a cross between a monster truck and a pushcart.

Why make such a robot?

The design of most robots is a very tedious process. Before starting, the designer must know what the robot can do and how to do it; after that, the designer can Start building a prototype of the robot, identify any problems with the design, come up with some unique improvements for better performance, and repeat the process before you run out of time and money.

The branch robot is completely different. It is not a static, single invention, but an idea, a flexible one that can be reconfigured in many ways. system.

As a modular robot, StickBot’s components can be added, adjusted and discarded as needed. It has strong reusability and flexibility while keeping very low the cost of.

For a simple model, the total build cost of StickBot is less than $100, with some components such as the actuator and motor drives) are an integral part of the robot's functionality.

#While other components can be replaced depending on the task being performed and the materials on hand. For example, Carroll is exploring using hot glue and tape to replace the ropes that bind the robot.

Carroll’s mentor, Mark Yim, has worked at the University of Pennsylvania for 17 years and is currently the director of the General Robotics, Automation, Sensing and Perception (GRASP) Laboratory. "The high versatility of modular robots offers great potential for the development of this technology, one iteration of which is self-configuring robots," Yim said.

“Humans are very good at adapting to different environments. When it’s cold, you put on your coat. Robots can do that too. If robots can change their shape and do different things... it gives you more possibilities. Sex."

Instant creation, and can also be applied to medical rehabilitation

One future application of StickBot is the global Rehabilitation settings in healthcare, either as prosthetics or for rehabilitation.

The designers asked: Are those expensive high-end medical procedures affordable for patients in every situation? Once a piece of high-tech equipment breaks, how difficult will it be to repair it?

Michelle J. Johnson, associate professor of rehabilitation at the University of Pennsylvania School of Medicine, agreed, saying the StickBot system could also potentially be used as a social, therapeutic, prosthetic or assistive robot. , or used to support immediate functional needs, help patients perform physical therapy exercises, etc.

"We did two things," designer Carroll said: "First, we reduced the material cost of the robot; second, we could Reduce complexity with fewer operational features. Having the flexibility to do more means you can help more people. If you can make it cheap, all the better."

The above is the detailed content of See you soon! You can make a robot by picking up a few branches... It can walk and grasp, and it can also be used in medical rehabilitation in the future.. For more information, please follow other related articles on the PHP Chinese website!

The AI Skills Gap Is Slowing Down Supply ChainsApr 26, 2025 am 11:13 AM

The AI Skills Gap Is Slowing Down Supply ChainsApr 26, 2025 am 11:13 AMThe term "AI-ready workforce" is frequently used, but what does it truly mean in the supply chain industry? According to Abe Eshkenazi, CEO of the Association for Supply Chain Management (ASCM), it signifies professionals capable of critic

How One Company Is Quietly Working To Transform AI ForeverApr 26, 2025 am 11:12 AM

How One Company Is Quietly Working To Transform AI ForeverApr 26, 2025 am 11:12 AMThe decentralized AI revolution is quietly gaining momentum. This Friday in Austin, Texas, the Bittensor Endgame Summit marks a pivotal moment, transitioning decentralized AI (DeAI) from theory to practical application. Unlike the glitzy commercial

Nvidia Releases NeMo Microservices To Streamline AI Agent DevelopmentApr 26, 2025 am 11:11 AM

Nvidia Releases NeMo Microservices To Streamline AI Agent DevelopmentApr 26, 2025 am 11:11 AMEnterprise AI faces data integration challenges The application of enterprise AI faces a major challenge: building systems that can maintain accuracy and practicality by continuously learning business data. NeMo microservices solve this problem by creating what Nvidia describes as "data flywheel", allowing AI systems to remain relevant through continuous exposure to enterprise information and user interaction. This newly launched toolkit contains five key microservices: NeMo Customizer handles fine-tuning of large language models with higher training throughput. NeMo Evaluator provides simplified evaluation of AI models for custom benchmarks. NeMo Guardrails implements security controls to maintain compliance and appropriateness

AI Paints A New Picture For The Future Of Art And DesignApr 26, 2025 am 11:10 AM

AI Paints A New Picture For The Future Of Art And DesignApr 26, 2025 am 11:10 AMAI: The Future of Art and Design Artificial intelligence (AI) is changing the field of art and design in unprecedented ways, and its impact is no longer limited to amateurs, but more profoundly affecting professionals. Artwork and design schemes generated by AI are rapidly replacing traditional material images and designers in many transactional design activities such as advertising, social media image generation and web design. However, professional artists and designers also find the practical value of AI. They use AI as an auxiliary tool to explore new aesthetic possibilities, blend different styles, and create novel visual effects. AI helps artists and designers automate repetitive tasks, propose different design elements and provide creative input. AI supports style transfer, which is to apply a style of image

How Zoom Is Revolutionizing Work With Agentic AI: From Meetings To MilestonesApr 26, 2025 am 11:09 AM

How Zoom Is Revolutionizing Work With Agentic AI: From Meetings To MilestonesApr 26, 2025 am 11:09 AMZoom, initially known for its video conferencing platform, is leading a workplace revolution with its innovative use of agentic AI. A recent conversation with Zoom's CTO, XD Huang, revealed the company's ambitious vision. Defining Agentic AI Huang d

The Existential Threat To UniversitiesApr 26, 2025 am 11:08 AM

The Existential Threat To UniversitiesApr 26, 2025 am 11:08 AMWill AI revolutionize education? This question is prompting serious reflection among educators and stakeholders. The integration of AI into education presents both opportunities and challenges. As Matthew Lynch of The Tech Edvocate notes, universit

The Prototype: American Scientists Are Looking For Jobs AbroadApr 26, 2025 am 11:07 AM

The Prototype: American Scientists Are Looking For Jobs AbroadApr 26, 2025 am 11:07 AMThe development of scientific research and technology in the United States may face challenges, perhaps due to budget cuts. According to Nature, the number of American scientists applying for overseas jobs increased by 32% from January to March 2025 compared with the same period in 2024. A previous poll showed that 75% of the researchers surveyed were considering searching for jobs in Europe and Canada. Hundreds of NIH and NSF grants have been terminated in the past few months, with NIH’s new grants down by about $2.3 billion this year, a drop of nearly one-third. The leaked budget proposal shows that the Trump administration is considering sharply cutting budgets for scientific institutions, with a possible reduction of up to 50%. The turmoil in the field of basic research has also affected one of the major advantages of the United States: attracting overseas talents. 35

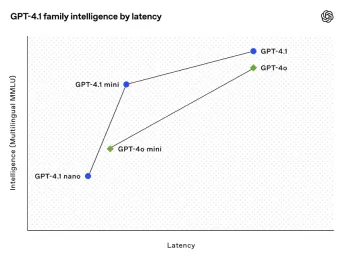

All About Open AI's Latest GPT 4.1 Family - Analytics VidhyaApr 26, 2025 am 10:19 AM

All About Open AI's Latest GPT 4.1 Family - Analytics VidhyaApr 26, 2025 am 10:19 AMOpenAI unveils the powerful GPT-4.1 series: a family of three advanced language models designed for real-world applications. This significant leap forward offers faster response times, enhanced comprehension, and drastically reduced costs compared t

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

Zend Studio 13.0.1

Powerful PHP integrated development environment

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

WebStorm Mac version

Useful JavaScript development tools