Technology peripherals

Technology peripherals AI

AI How data and artificial intelligence are changing the automotive industry

How data and artificial intelligence are changing the automotive industryHow data and artificial intelligence are changing the automotive industry

Harnessing data and artificial intelligence to power advanced safety features in connected vehicles is just one example of how the automotive industry is changing as a result of digital transformation. However, the impact of digital transformation is not limited to advanced safety technology, but also includes predictive maintenance and other cost-saving initiatives.

Artificial Intelligence Simplifies Work Processes as well as Supply Chains

Using artificial intelligence to streamline supply chains in the automotive industry can be a huge advantage for businesses. AI can enable faster, more informed decisions and help identify potential risks. It can also help create a safer workplace.

Benefits of implementing artificial intelligence include real-time monitoring of operations, streamlined workflows, and timely insights. It can also predict unforeseen anomalies and bottlenecks. For example, a poorly performing car can be fixed before it results in lost sales.

Artificial intelligence can also help companies stay competitive. It allows dealers to work more efficiently and improve customer relationships. It can even provide tailor-made financial solutions to improve dealer profitability.

Artificial intelligence can help companies better manage inventory and prevent inventory backlogs. It can also predict demand and plan downtime. Additionally, it helps analysts analyze patterns in the market and make accurate predictions. It can also help eliminate bottlenecks in the supply chain and simplify production scheduling.

AI-based automation tools ensure warehouses run efficiently, record inventory parameters, and analyze workplace safety data. They can also ensure that manufacturers are aware of potential risks.

Artificial intelligence reduces costs by improving quality and reducing waste

In the automotive industry, using artificial intelligence to reduce costs by improving quality and reducing waste has huge implications potential. However, developing the business case and integrating the technology into the enterprise can take some time.

Early adopters can benefit from various advantages of using artificial intelligence. For example, the ability to predict failures can reduce operating costs and downtime. Likewise, incorporating sensor data from IoT can help improve supply chain planning.

Ultimately, successful implementation requires strategic changes across the enterprise. Businesses must develop robust analytics programs, modern software disciplines, and important governance processes.

Hyperautomation will be the driving force behind digital transformation

Whether it is customer-facing services, transactions or business processes, automation technology can Improving quality, efficiency and productivity, they can also reduce costs. But before we can realize the full benefits of automation, we must redesign processes and implement new technologies. This can be an extremely complex and challenging task.

Many businesses have identified significant opportunities to apply automation to their operations, but need help implementing new approaches at scale. This can be a daunting challenge as there are many different processes and technologies involved.

To ensure that the automation program is ready to launch, we need to start with a thorough assessment of the business's processes and skills. Then there’s the need to tailor the chosen technology and create a roadmap for large-scale automation, balancing short-term tactical wins with long-term vision.

Among these technologies, we will need to adopt robotic process automation, natural language processing, and deep learning. These technologies help us identify customer emotional tones, improve call routing, and increase sales.

Artificial Intelligence Advanced Safety Features for Connected Vehicles

Using artificial intelligence to provide advanced safety features for connected vehicles can help drivers avoid road accidents . AI can also monitor and detect distracted, erratic and drowsy driving.

Distributed road safety networks need to know the position, speed and topology of moving objects. This information can be used to assess risk and implement interventions. In addition, the network can provide early warning of dangerous situations.

As technology advances, more advanced automotive safety features are being developed. These include radar-based detection units, camera-based machine vision systems and automatic braking. These features can help avoid collisions between commercial vehicle fleets and retrain drivers to drive more safely. These technologies are increasingly important to the design of autonomous vehicles.

Artificial Intelligence Predictive Maintenance

There are many benefits to using artificial intelligence-driven predictive maintenance in the automotive industry. These include improving safety, reducing downtime and saving money. Additionally, these solutions enhance user experience.

Predictive maintenance solutions monitor a vehicle’s sensors and alert drivers of any issues in real time. It can proactively alert drivers of potential problems before they lead to a crash, and can also optimize auxiliary power consumption and heat rates, among other things.

The main advantage of predictive maintenance is the ability to detect and avoid problems before they occur. These tools enable businesses to make better decisions and maximize the life of their assets. They can also increase yields by 20 to 25 percent. Additionally, they reduce maintenance costs by 25% to 30%.

One of the most significant advantages of AI-powered predictive maintenance in the automotive industry is the amount of data it can process. This is achieved through big data and machine learning. The technology can process large amounts of sensor data more efficiently than humans and spot anomalies in utility data.

The above is the detailed content of How data and artificial intelligence are changing the automotive industry. For more information, please follow other related articles on the PHP Chinese website!

Tesla's Robovan Was The Hidden Gem In 2024's Robotaxi TeaserApr 22, 2025 am 11:48 AM

Tesla's Robovan Was The Hidden Gem In 2024's Robotaxi TeaserApr 22, 2025 am 11:48 AMSince 2008, I've championed the shared-ride van—initially dubbed the "robotjitney," later the "vansit"—as the future of urban transportation. I foresee these vehicles as the 21st century's next-generation transit solution, surpas

Sam's Club Bets On AI To Eliminate Receipt Checks And Enhance RetailApr 22, 2025 am 11:29 AM

Sam's Club Bets On AI To Eliminate Receipt Checks And Enhance RetailApr 22, 2025 am 11:29 AMRevolutionizing the Checkout Experience Sam's Club's innovative "Just Go" system builds on its existing AI-powered "Scan & Go" technology, allowing members to scan purchases via the Sam's Club app during their shopping trip.

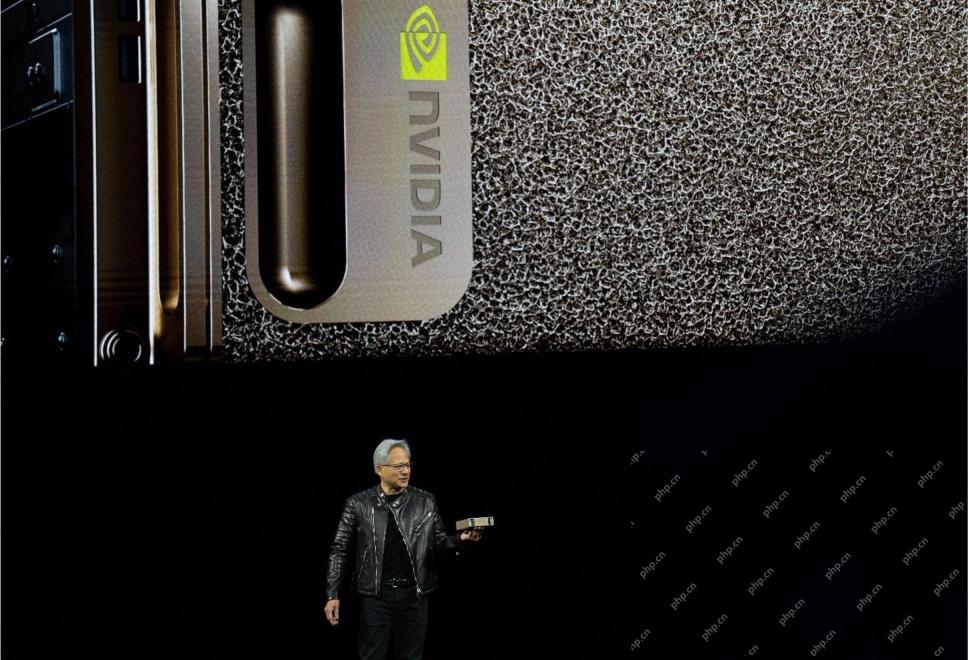

Nvidia's AI Omniverse Expands At GTC 2025Apr 22, 2025 am 11:28 AM

Nvidia's AI Omniverse Expands At GTC 2025Apr 22, 2025 am 11:28 AMNvidia's Enhanced Predictability and New Product Lineup at GTC 2025 Nvidia, a key player in AI infrastructure, is focusing on increased predictability for its clients. This involves consistent product delivery, meeting performance expectations, and

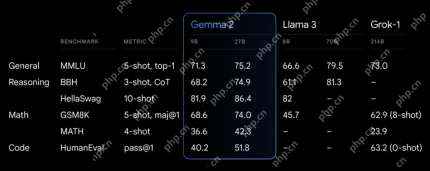

Exploring the Capabilities of Google's Gemma 2 ModelsApr 22, 2025 am 11:26 AM

Exploring the Capabilities of Google's Gemma 2 ModelsApr 22, 2025 am 11:26 AMGoogle's Gemma 2: A Powerful, Efficient Language Model Google's Gemma family of language models, celebrated for efficiency and performance, has expanded with the arrival of Gemma 2. This latest release comprises two models: a 27-billion parameter ver

The Next Wave of GenAI: Perspectives with Dr. Kirk Borne - Analytics VidhyaApr 22, 2025 am 11:21 AM

The Next Wave of GenAI: Perspectives with Dr. Kirk Borne - Analytics VidhyaApr 22, 2025 am 11:21 AMThis Leading with Data episode features Dr. Kirk Borne, a leading data scientist, astrophysicist, and TEDx speaker. A renowned expert in big data, AI, and machine learning, Dr. Borne offers invaluable insights into the current state and future traje

AI For Runners And Athletes: We're Making Excellent ProgressApr 22, 2025 am 11:12 AM

AI For Runners And Athletes: We're Making Excellent ProgressApr 22, 2025 am 11:12 AMThere were some very insightful perspectives in this speech—background information about engineering that showed us why artificial intelligence is so good at supporting people’s physical exercise. I will outline a core idea from each contributor’s perspective to demonstrate three design aspects that are an important part of our exploration of the application of artificial intelligence in sports. Edge devices and raw personal data This idea about artificial intelligence actually contains two components—one related to where we place large language models and the other is related to the differences between our human language and the language that our vital signs “express” when measured in real time. Alexander Amini knows a lot about running and tennis, but he still

Jamie Engstrom On Technology, Talent And Transformation At CaterpillarApr 22, 2025 am 11:10 AM

Jamie Engstrom On Technology, Talent And Transformation At CaterpillarApr 22, 2025 am 11:10 AMCaterpillar's Chief Information Officer and Senior Vice President of IT, Jamie Engstrom, leads a global team of over 2,200 IT professionals across 28 countries. With 26 years at Caterpillar, including four and a half years in her current role, Engst

New Google Photos Update Makes Any Photo Pop With Ultra HDR QualityApr 22, 2025 am 11:09 AM

New Google Photos Update Makes Any Photo Pop With Ultra HDR QualityApr 22, 2025 am 11:09 AMGoogle Photos' New Ultra HDR Tool: A Quick Guide Enhance your photos with Google Photos' new Ultra HDR tool, transforming standard images into vibrant, high-dynamic-range masterpieces. Ideal for social media, this tool boosts the impact of any photo,

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

SublimeText3 English version

Recommended: Win version, supports code prompts!

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

SublimeText3 Mac version

God-level code editing software (SublimeText3)

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

Atom editor mac version download

The most popular open source editor