Dealing with the impact of the global recession, while dealing with ongoing supply chain disruptions, labor shortages and rising energy costs, is forcing manufacturing companies to explore innovative ways to address business challenges.

Seeking to improve operational efficiency, ensure long-term growth and stay ahead of the competition, manufacturers are investing more in digital technologies such as MES, SCADA/HMI, predictive maintenance, simulation/digital twins, and edge-to-cloud . Manufacturing will benefit from the additional data these technologies bring, providing deeper insights for operational improvements.

Many manufacturers believe that increased capital investment is critical to improving productivity, especially in the process of increasing production capacity, improving quality and reducing costs. Manufacturers will invest more in software, acquisitions, new equipment and international expansion as they seek to achieve broader growth goals, accelerate digitalization, transition to net zero and open up new global markets.

Despite the current uncertainty, manufacturers recognize that investment is critical to boost growth, increase productivity and remain competitive in the global marketplace. It’s no secret that the manufacturing landscape is changing rapidly, and tomorrow’s manufacturing leaders need to stay ahead of the game today. Demand for new products and shortened delivery times show no signs of slowing down, with customer relationships reliant on fast, efficient “on-demand” delivery.

World-class manufacturers measure and monitor an agreed-upon set of KPIs and use them to evaluate business performance and as input to decision-making. Traditional metrics such as overall equipment efficiency and downtime are effective but have limitations when assessing overall manufacturing efficiency and productivity. Driving continuous improvement throughout the manufacturing process requires additional KPI metrics that take into account all areas that impact productivity, thereby increasing visibility.

1. Leverage real-time data to make actionable improvements

Measuring OEE is an important part of implementing digital lean and performance improvement initiatives. The data provided in the performance system must be processed quickly, otherwise, production managers will have difficulty discovering the root cause of the problem. Shop floor teams are encouraged to use data to uncover the causes of process inefficiencies to drive improvements, creating a culture of continuous improvement as operators actively engage with the system and see the value derived from it.

2. Ensure regulatory compliance and quality

Real-time visibility into quality issues, such as non-compliance events or process out-of-control, is critical to increasing yields, reducing production waste and avoiding costly Product recalls are critical. The impact of a product recall on a brand's reputation can be huge and the associated costs/hefty fines can be huge, not just for production. Understanding process capabilities across a manufacturing facility is critical to reducing low-quality costs, promoting continuous improvement, and creating sustainable competitive advantage.

3. Manage Energy Consumption

As energy costs continue to rise to unprecedented levels and energy contracts are about to expire, business owners will be concerned about how to manage rising energy bills. and reduce energy consumption. Measure and monitor energy usage in real time, rather than through monthly or quarterly energy bills, allowing for comprehensive corrective action.

Additionally, help proactively reduce energy by integrating energy and production data to identify improvement opportunities! Not forgetting the importance of achieving long-term sustainability and carbon reduction targets is another benefit of implementing digital technologies to support energy reduction targets.

4. Reduce production losses

Availability losses such as planned or unplanned downtime, machine installation time, inventory turnover and changeover time, will have a negative impact on OEE and performance . However, aspects such as the impact of non-productive tasks, machine downtime and its impact on other production are difficult to capture. Identifying inefficiencies throughout the production process is key to providing the real-time information needed to take corrective action.

5. Optimize maintenance activities

Unscheduled maintenance will lead to production losses, increased parts costs and time loss to repair problems, and the cost is significantly higher than planned maintenance. Adopt a more proactive approach to preventive maintenance to coincide with planned production downtime, significantly reducing costs.

Preventive maintenance needs to be effectively controlled and managed to ensure that equipment continues to produce high-quality products. Visibility into equipment availability and performance can help reduce unplanned downtime, optimize maintenance activities and get the most value from your assets.

6. Understand Labor Costs

Having the right number of people and a balance of skills on the shop floor is a huge juggling act! Too little can create bottlenecks and lead to missed production deadlines, too much can cause unnecessary labor costs and impact profits.

Obtaining detailed workforce information, such as how many employees are needed on a production line, required skill sets, and how long it takes to complete a job, will help paint a picture of your workforce needs. Likewise, understanding the relationship between employee performance and output, how profitable work is being run, and understanding the true cost of labor are also important considerations when optimizing workforce performance and ensuring maximum productivity.

7. Reduce Goods Cost

Most manufacturers include direct materials, labor and overhead when estimating costs. Here are three things to understand when trying to reduce your cost of goods, which can help achieve your business's bottom-line KPIs, including improving profit margins, ensuring business sustainability, and improving customer satisfaction. Increased visibility through digital technology and real-time data analytics can reduce cost of goods.

The above is the detailed content of What are the benefits of achieving real-time manufacturing visibility?. For more information, please follow other related articles on the PHP Chinese website!

Tesla's Robovan Was The Hidden Gem In 2024's Robotaxi TeaserApr 22, 2025 am 11:48 AM

Tesla's Robovan Was The Hidden Gem In 2024's Robotaxi TeaserApr 22, 2025 am 11:48 AMSince 2008, I've championed the shared-ride van—initially dubbed the "robotjitney," later the "vansit"—as the future of urban transportation. I foresee these vehicles as the 21st century's next-generation transit solution, surpas

Sam's Club Bets On AI To Eliminate Receipt Checks And Enhance RetailApr 22, 2025 am 11:29 AM

Sam's Club Bets On AI To Eliminate Receipt Checks And Enhance RetailApr 22, 2025 am 11:29 AMRevolutionizing the Checkout Experience Sam's Club's innovative "Just Go" system builds on its existing AI-powered "Scan & Go" technology, allowing members to scan purchases via the Sam's Club app during their shopping trip.

Nvidia's AI Omniverse Expands At GTC 2025Apr 22, 2025 am 11:28 AM

Nvidia's AI Omniverse Expands At GTC 2025Apr 22, 2025 am 11:28 AMNvidia's Enhanced Predictability and New Product Lineup at GTC 2025 Nvidia, a key player in AI infrastructure, is focusing on increased predictability for its clients. This involves consistent product delivery, meeting performance expectations, and

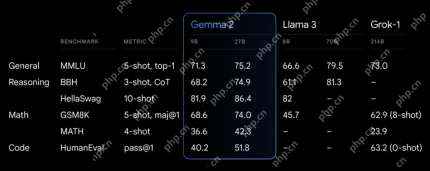

Exploring the Capabilities of Google's Gemma 2 ModelsApr 22, 2025 am 11:26 AM

Exploring the Capabilities of Google's Gemma 2 ModelsApr 22, 2025 am 11:26 AMGoogle's Gemma 2: A Powerful, Efficient Language Model Google's Gemma family of language models, celebrated for efficiency and performance, has expanded with the arrival of Gemma 2. This latest release comprises two models: a 27-billion parameter ver

The Next Wave of GenAI: Perspectives with Dr. Kirk Borne - Analytics VidhyaApr 22, 2025 am 11:21 AM

The Next Wave of GenAI: Perspectives with Dr. Kirk Borne - Analytics VidhyaApr 22, 2025 am 11:21 AMThis Leading with Data episode features Dr. Kirk Borne, a leading data scientist, astrophysicist, and TEDx speaker. A renowned expert in big data, AI, and machine learning, Dr. Borne offers invaluable insights into the current state and future traje

AI For Runners And Athletes: We're Making Excellent ProgressApr 22, 2025 am 11:12 AM

AI For Runners And Athletes: We're Making Excellent ProgressApr 22, 2025 am 11:12 AMThere were some very insightful perspectives in this speech—background information about engineering that showed us why artificial intelligence is so good at supporting people’s physical exercise. I will outline a core idea from each contributor’s perspective to demonstrate three design aspects that are an important part of our exploration of the application of artificial intelligence in sports. Edge devices and raw personal data This idea about artificial intelligence actually contains two components—one related to where we place large language models and the other is related to the differences between our human language and the language that our vital signs “express” when measured in real time. Alexander Amini knows a lot about running and tennis, but he still

Jamie Engstrom On Technology, Talent And Transformation At CaterpillarApr 22, 2025 am 11:10 AM

Jamie Engstrom On Technology, Talent And Transformation At CaterpillarApr 22, 2025 am 11:10 AMCaterpillar's Chief Information Officer and Senior Vice President of IT, Jamie Engstrom, leads a global team of over 2,200 IT professionals across 28 countries. With 26 years at Caterpillar, including four and a half years in her current role, Engst

New Google Photos Update Makes Any Photo Pop With Ultra HDR QualityApr 22, 2025 am 11:09 AM

New Google Photos Update Makes Any Photo Pop With Ultra HDR QualityApr 22, 2025 am 11:09 AMGoogle Photos' New Ultra HDR Tool: A Quick Guide Enhance your photos with Google Photos' new Ultra HDR tool, transforming standard images into vibrant, high-dynamic-range masterpieces. Ideal for social media, this tool boosts the impact of any photo,

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Atom editor mac version download

The most popular open source editor

SublimeText3 Linux new version

SublimeText3 Linux latest version

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

Zend Studio 13.0.1

Powerful PHP integrated development environment

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.