Artificial intelligence reshapes fashion design and production

Artificial intelligence technology and robotics are driving changes in the fashion industry. From market analysis to custom designs to waste reduction, AI opens the door for designers to stay current and responsive.

With robots picking and packing goods in logistics centers, it’s no surprise that they are also producing clothing and shoes. Now, artificial intelligence is driving the rise of fast fashion.

Fashion companies are currently using artificial intelligence to predict style trends, textures and colors. Even Google and Amazon are getting involved. Google launched Project Muze, which uses artificial intelligence to design clothing based on fashion trends and online merchant sales data. Amazon is also working on a project that uses machine learning to identify “fashionable” items that can then be replicated and produced offline under the Amazon Essentials product line.

Paris-based Heuritech uses deep learning and image recognition technology to help designers at brands like Dior identify trends across seasons, markets and countries. Designers select representative items, and Heuritech's algorithms scan thousands of public social media images for more than 3,000 details, including fabrics, shapes and colors. Heuritech claims that its computer vision system will predict fashion trends within a year with 90% accuracy. Designers, in turn, use this data to guide their fashion lines.

Precision Clothing

AI works best with input from human designers – some of the initial Muze project sketches were simple doodles, but with guidance from on-site designers, AI can produce customizations clothing.

Customization is the future of retail, and it’s everything from personalized M&Ms to Nike kicks. With the help of artificial intelligence and robotic sewing machines, custom designs are moving from large fashion stores to the Etsy online platform.

Fashion designers can take 3D images of customers and design unique custom garments based on their exact measurements. After creating a project on a digital model, designers send the electronic file to a robotic sewing machine, such as SoftWear Automation’s Sewbot. Sewbot extracts the necessary crop data and starts cutting and stitching. The machine doesn't care whether it makes one piece or 100, the process is the same.

Sustainability Factor

What cannot be ignored is the global advantage of automated design and production, especially in the field of fast fashion. Automated robots use artificial intelligence to sew pieces of cloth together, which can significantly reduce production costs, not only in terms of labor, but also bring production closer to the point of sale. It also helps build more reliable supply chains — an advantage that has become even more valuable after the coronavirus pandemic crippled retailers’ sourcing and fulfillment capabilities.

AI-based fashion design also improves sustainability. The software determines the most efficient way to use fabric to reduce waste. Additionally, fashion can be produced on demand, reducing overhead and waste.

Tokyo-based fashion lab Synflux is solving sustainability issues through design. Synflux uses artificial intelligence to develop what it calls “algorithmic fashion.” Using 3D scans of the human body, machine learning algorithms can create clothing patterns to minimize fabric waste. Designers use computer-aided design software to model and piece together patterns for designing garments with less waste.

Artificial intelligence brings a new level of customization to the ever-evolving fashion industry. It has the power to change the way clothing is sourced and produced, and reduce its carbon footprint. AI also has the potential to level the playing field for designers, allowing online Etsy designers to compete with high-fashion brands in offering custom-made garments.

The above is the detailed content of Artificial intelligence reshapes fashion design and production. For more information, please follow other related articles on the PHP Chinese website!

Tesla's Robovan Was The Hidden Gem In 2024's Robotaxi TeaserApr 22, 2025 am 11:48 AM

Tesla's Robovan Was The Hidden Gem In 2024's Robotaxi TeaserApr 22, 2025 am 11:48 AMSince 2008, I've championed the shared-ride van—initially dubbed the "robotjitney," later the "vansit"—as the future of urban transportation. I foresee these vehicles as the 21st century's next-generation transit solution, surpas

Sam's Club Bets On AI To Eliminate Receipt Checks And Enhance RetailApr 22, 2025 am 11:29 AM

Sam's Club Bets On AI To Eliminate Receipt Checks And Enhance RetailApr 22, 2025 am 11:29 AMRevolutionizing the Checkout Experience Sam's Club's innovative "Just Go" system builds on its existing AI-powered "Scan & Go" technology, allowing members to scan purchases via the Sam's Club app during their shopping trip.

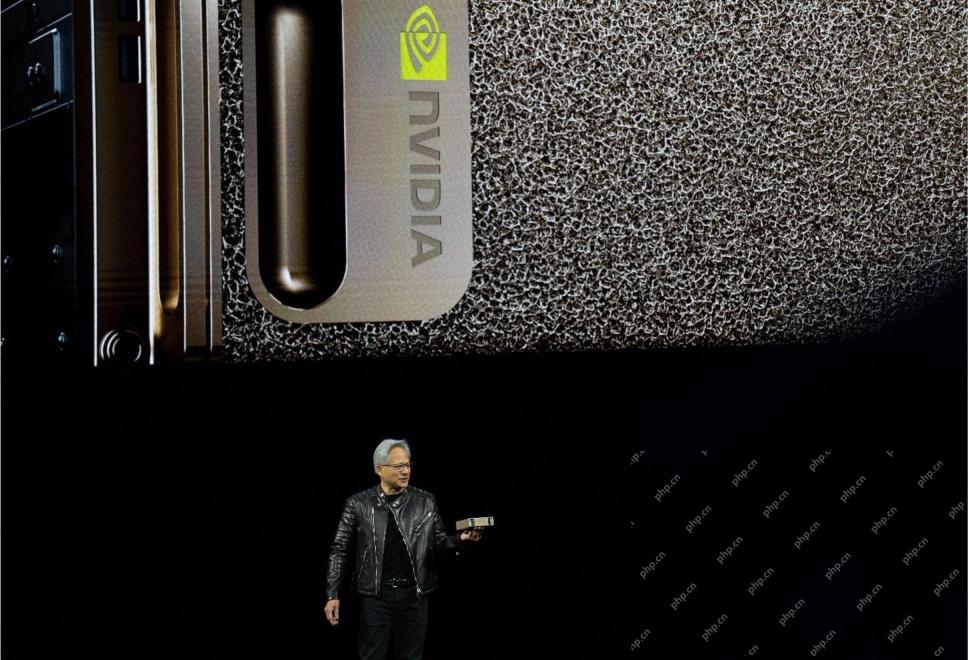

Nvidia's AI Omniverse Expands At GTC 2025Apr 22, 2025 am 11:28 AM

Nvidia's AI Omniverse Expands At GTC 2025Apr 22, 2025 am 11:28 AMNvidia's Enhanced Predictability and New Product Lineup at GTC 2025 Nvidia, a key player in AI infrastructure, is focusing on increased predictability for its clients. This involves consistent product delivery, meeting performance expectations, and

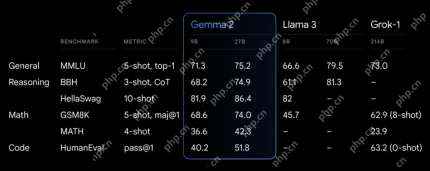

Exploring the Capabilities of Google's Gemma 2 ModelsApr 22, 2025 am 11:26 AM

Exploring the Capabilities of Google's Gemma 2 ModelsApr 22, 2025 am 11:26 AMGoogle's Gemma 2: A Powerful, Efficient Language Model Google's Gemma family of language models, celebrated for efficiency and performance, has expanded with the arrival of Gemma 2. This latest release comprises two models: a 27-billion parameter ver

The Next Wave of GenAI: Perspectives with Dr. Kirk Borne - Analytics VidhyaApr 22, 2025 am 11:21 AM

The Next Wave of GenAI: Perspectives with Dr. Kirk Borne - Analytics VidhyaApr 22, 2025 am 11:21 AMThis Leading with Data episode features Dr. Kirk Borne, a leading data scientist, astrophysicist, and TEDx speaker. A renowned expert in big data, AI, and machine learning, Dr. Borne offers invaluable insights into the current state and future traje

AI For Runners And Athletes: We're Making Excellent ProgressApr 22, 2025 am 11:12 AM

AI For Runners And Athletes: We're Making Excellent ProgressApr 22, 2025 am 11:12 AMThere were some very insightful perspectives in this speech—background information about engineering that showed us why artificial intelligence is so good at supporting people’s physical exercise. I will outline a core idea from each contributor’s perspective to demonstrate three design aspects that are an important part of our exploration of the application of artificial intelligence in sports. Edge devices and raw personal data This idea about artificial intelligence actually contains two components—one related to where we place large language models and the other is related to the differences between our human language and the language that our vital signs “express” when measured in real time. Alexander Amini knows a lot about running and tennis, but he still

Jamie Engstrom On Technology, Talent And Transformation At CaterpillarApr 22, 2025 am 11:10 AM

Jamie Engstrom On Technology, Talent And Transformation At CaterpillarApr 22, 2025 am 11:10 AMCaterpillar's Chief Information Officer and Senior Vice President of IT, Jamie Engstrom, leads a global team of over 2,200 IT professionals across 28 countries. With 26 years at Caterpillar, including four and a half years in her current role, Engst

New Google Photos Update Makes Any Photo Pop With Ultra HDR QualityApr 22, 2025 am 11:09 AM

New Google Photos Update Makes Any Photo Pop With Ultra HDR QualityApr 22, 2025 am 11:09 AMGoogle Photos' New Ultra HDR Tool: A Quick Guide Enhance your photos with Google Photos' new Ultra HDR tool, transforming standard images into vibrant, high-dynamic-range masterpieces. Ideal for social media, this tool boosts the impact of any photo,

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Atom editor mac version download

The most popular open source editor

SublimeText3 English version

Recommended: Win version, supports code prompts!

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.