Technology peripherals

Technology peripherals AI

AI Tsinghua's Black Technology appears on the cover of Science: a film is attached to a round tube to transform it into a complex 3D structure in seconds

Tsinghua's Black Technology appears on the cover of Science: a film is attached to a round tube to transform it into a complex 3D structure in secondsTsinghua's Black Technology appears on the cover of Science: a film is attached to a round tube to transform it into a complex 3D structure in seconds

In industrial practice, the assembly of parts and electronic equipment is a key link for the normal operation of complex mechanical equipment. In the past, the substrates on which these components were assembled were mainly flat, and the few parts assembled on curved surfaces were mostly limited to simple structures and difficult to modify.

For complex three-dimensional structural parts, can it be installed on a curved substrate while making it easy to install and modify? Recently, the team of Professor Zhang Yihui of Tsinghua University proposed a new assembly strategy to solve this problem, and published the results in the latest issue of Science Advance.

Paper link: https://www.science.org/doi/10.1126/sciadv.abm6922

The paper mentioned that electronic devices with engineered three-dimensional structures are essential for friction sensing, wide-field optical imaging and flow velocity measurement. Recent advances in mechanically guided assembly establish defined three-dimensional structural routes in high-performance materials through controlled rolling/folding/bending deformations. However, the resulting three-dimensional structures are mostly formed on flat substrates and cannot be directly transferred to another curved substrate.

This study introduces an ordered assembly strategy that can transform 2D films into complex 3D structures on different curved surfaces. This strategy utilizes predetermined mechanical loading to deform the curved elastomeric substrate into a planar/cylindrical structure, which is then driven by additional uniaxial/biaxial pretensioning to drive the buckle-guided assembly.

Through mechanical modeling, the predetermined load can be accurately released and the parts with complex three-dimensional structures can be assembled in an orderly manner on the curved surface. In the example in this article, dozens of these are assembled on a curved base. Structure-like parts. These include tunable dipole antennas, flow sensors in water pipes, integrated electronic systems that can be conformally integrated with the heart, and more.

The picture above is a conceptual diagram of the orderly assembly strategy of complex three-dimensional structures on curved surfaces. .

(A) Use the formation of a three-dimensional decorative mask of the human face to illustrate the orderly assembly strategy. The two images on the right correspond to finite element analysis predictions and optical images of the three-dimensional structure in a silver (5 m) and PET (75 m) bilayer.

(B) The picture above is a finite element analysis result of a spiral base and a spiral base that can be flattened by torsional and tensile loads. The bottom panel shows the ordered assembly process of three-dimensional leaf-like structures on a spiral substrate, along with finite element analysis predictions and optical imaging images.

(C) Conceptual diagram of assembling a three-dimensional structure on the inner surface of a cylindrical tube. Before integration with the two-dimensional precursor, the substrate is cut obliquely and flattened by bending deformation. , and then pre-stretched. The bottom panel shows the orderly assembly process of a layered three-dimensional helical structure [aluminum (2.5m)/PET (30m)] inside a cylindrical tube, accompanied by finite element analysis predictions and optical images.

(D) Illustration of the assembly process of three-dimensional structures on a substrate with a Möbius strip shape, and an ant-like structure assembled on the substrate [Al (2.5 m)/ PET (30 m)] finite element analysis predictions and optical images.

The picture above shows a complex three-dimensional structure assembled on a curved surface that can be flattened.

(A) is a schematic diagram of a horseshoe-shaped curved base, which can be flattened by uniaxial stretching. (B) Optical image illustrating the assembly process of three-dimensional ribbon structures on a horseshoe-shaped substrate. (C) Finite element analysis and empirical results of the generative matrix profile of a hemispherical elastomeric substrate under varying degrees of biaxial stretching. R0 represents the radius of the initial hemisphere. (D) Finite element analysis prediction of the maximum principal strain profile of a hemispherical matrix under varying degrees of biaxial stretching.

(E) Comparison of straight ribbons (Lribbon) of different lengths assembled on a hemispherical base as predicted by finite element analysis. (F) 2D geometries, FEA predictions, and experimental images of various 3D structures assembled on the convex and concave surfaces of a hemispherical substrate. G to J: Inverse design of a semi-elliptical surface assembled on a hemispherical base. (K to N) Inverse design of small hemispheres with the same height (hi) assembled at different spatial locations on a hemispherical base. (O and P) Optical images of a network of spiral microscale structures and tiny three-dimensional rhombohedral ribbon-like microstructures assembled on the surface of a brainoid.

The picture above shows the assembly of a complex three-dimensional structure on a cylindrical/quasi-cylindrical surface.

(A) Schematic illustration of the aorta model used as a curved base and the assembly process of helical and double helix structures on this base by compression buckling.

(B) The process of assembling straight strips of different lengths on a cylindrical base through tensile buckling.

(C) Two-dimensional geometries, finite element analysis predictions and experimental images of various three-dimensional structures assembled on cylindrical substrates.

(D) Experimental images of 2D precursor, finite element analysis predictions, and kirigami-inspired scale-like 3D structures formed by tensile buckling.

(E) Finite element analysis predictions and experimental images demonstrate the orderly assembly process of kirigami-inspired arrays of scale structures on Archimedean spiral fibers.

(F to H) Reverse design of assembling helical structures with the same height and spacing at different spatial regions on the helical fiber.

Author Team

The corresponding author of this article is Dr. Zhang Yihui, Department of Engineering Mechanics, School of Aeronautics and Astronautics, Tsinghua University Permanent professor.

Received a PhD degree from the Department of Engineering Mechanics, School of Aerospace and Astronautics, Tsinghua University in 2011. From 2011 to 2015, he served as Postdoctoral Fellow and Research Assistant Professor in the Department of Civil and Environmental Engineering at Northwestern University. In 2015, he joined the Department of Engineering Mechanics of Tsinghua University and served successively as associate professor, permanent associate professor and permanent professor.

The main research fields are mechanics-guided three-dimensional microstructure assembly, unconventional soft materials, flexible and malleable electronic devices, smart materials and structural mechanics. So far, 5 authorized Chinese invention patents have been obtained , 3 U.S. invention patents, 1 academic monograph, and more than 150 SCI papers, among which the corresponding author has been published in "Science", "Nature", "Nature Materials", "Nature Electronics", "Nature Reviews Materials", " He has published more than 80 high-level academic papers in journals such as Nature Communications, Science Advances, PNAS, JMPS, Advanced Materials, and ACS Nano.

The two co-first authors, Xue Zhaoguo and Jin Tianqi, are both from the Applied Mechanics Laboratory of the Department of Engineering Mechanics of Tsinghua University. Xue Zhaoguo is mainly responsible for conceptualization, data curation, formal analysis, funding acquisition, investigation, methodology, project management, resources, software, validation, visualization, paper writing, review and editing. Jin Tianqi is mainly responsible for conceptualization, data management, formal analysis, investigation, methodology, software, visualization and paper writing.

The above is the detailed content of Tsinghua's Black Technology appears on the cover of Science: a film is attached to a round tube to transform it into a complex 3D structure in seconds. For more information, please follow other related articles on the PHP Chinese website!

The AI Skills Gap Is Slowing Down Supply ChainsApr 26, 2025 am 11:13 AM

The AI Skills Gap Is Slowing Down Supply ChainsApr 26, 2025 am 11:13 AMThe term "AI-ready workforce" is frequently used, but what does it truly mean in the supply chain industry? According to Abe Eshkenazi, CEO of the Association for Supply Chain Management (ASCM), it signifies professionals capable of critic

How One Company Is Quietly Working To Transform AI ForeverApr 26, 2025 am 11:12 AM

How One Company Is Quietly Working To Transform AI ForeverApr 26, 2025 am 11:12 AMThe decentralized AI revolution is quietly gaining momentum. This Friday in Austin, Texas, the Bittensor Endgame Summit marks a pivotal moment, transitioning decentralized AI (DeAI) from theory to practical application. Unlike the glitzy commercial

Nvidia Releases NeMo Microservices To Streamline AI Agent DevelopmentApr 26, 2025 am 11:11 AM

Nvidia Releases NeMo Microservices To Streamline AI Agent DevelopmentApr 26, 2025 am 11:11 AMEnterprise AI faces data integration challenges The application of enterprise AI faces a major challenge: building systems that can maintain accuracy and practicality by continuously learning business data. NeMo microservices solve this problem by creating what Nvidia describes as "data flywheel", allowing AI systems to remain relevant through continuous exposure to enterprise information and user interaction. This newly launched toolkit contains five key microservices: NeMo Customizer handles fine-tuning of large language models with higher training throughput. NeMo Evaluator provides simplified evaluation of AI models for custom benchmarks. NeMo Guardrails implements security controls to maintain compliance and appropriateness

AI Paints A New Picture For The Future Of Art And DesignApr 26, 2025 am 11:10 AM

AI Paints A New Picture For The Future Of Art And DesignApr 26, 2025 am 11:10 AMAI: The Future of Art and Design Artificial intelligence (AI) is changing the field of art and design in unprecedented ways, and its impact is no longer limited to amateurs, but more profoundly affecting professionals. Artwork and design schemes generated by AI are rapidly replacing traditional material images and designers in many transactional design activities such as advertising, social media image generation and web design. However, professional artists and designers also find the practical value of AI. They use AI as an auxiliary tool to explore new aesthetic possibilities, blend different styles, and create novel visual effects. AI helps artists and designers automate repetitive tasks, propose different design elements and provide creative input. AI supports style transfer, which is to apply a style of image

How Zoom Is Revolutionizing Work With Agentic AI: From Meetings To MilestonesApr 26, 2025 am 11:09 AM

How Zoom Is Revolutionizing Work With Agentic AI: From Meetings To MilestonesApr 26, 2025 am 11:09 AMZoom, initially known for its video conferencing platform, is leading a workplace revolution with its innovative use of agentic AI. A recent conversation with Zoom's CTO, XD Huang, revealed the company's ambitious vision. Defining Agentic AI Huang d

The Existential Threat To UniversitiesApr 26, 2025 am 11:08 AM

The Existential Threat To UniversitiesApr 26, 2025 am 11:08 AMWill AI revolutionize education? This question is prompting serious reflection among educators and stakeholders. The integration of AI into education presents both opportunities and challenges. As Matthew Lynch of The Tech Edvocate notes, universit

The Prototype: American Scientists Are Looking For Jobs AbroadApr 26, 2025 am 11:07 AM

The Prototype: American Scientists Are Looking For Jobs AbroadApr 26, 2025 am 11:07 AMThe development of scientific research and technology in the United States may face challenges, perhaps due to budget cuts. According to Nature, the number of American scientists applying for overseas jobs increased by 32% from January to March 2025 compared with the same period in 2024. A previous poll showed that 75% of the researchers surveyed were considering searching for jobs in Europe and Canada. Hundreds of NIH and NSF grants have been terminated in the past few months, with NIH’s new grants down by about $2.3 billion this year, a drop of nearly one-third. The leaked budget proposal shows that the Trump administration is considering sharply cutting budgets for scientific institutions, with a possible reduction of up to 50%. The turmoil in the field of basic research has also affected one of the major advantages of the United States: attracting overseas talents. 35

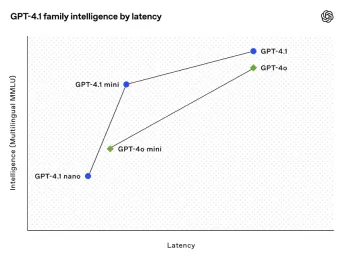

All About Open AI's Latest GPT 4.1 Family - Analytics VidhyaApr 26, 2025 am 10:19 AM

All About Open AI's Latest GPT 4.1 Family - Analytics VidhyaApr 26, 2025 am 10:19 AMOpenAI unveils the powerful GPT-4.1 series: a family of three advanced language models designed for real-world applications. This significant leap forward offers faster response times, enhanced comprehension, and drastically reduced costs compared t

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

WebStorm Mac version

Useful JavaScript development tools

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

SublimeText3 English version

Recommended: Win version, supports code prompts!