Home >Common Problem >What does the tall formwork monitoring system consist of?

What does the tall formwork monitoring system consist of?

- 青灯夜游Original

- 2022-11-18 10:24:366712browse

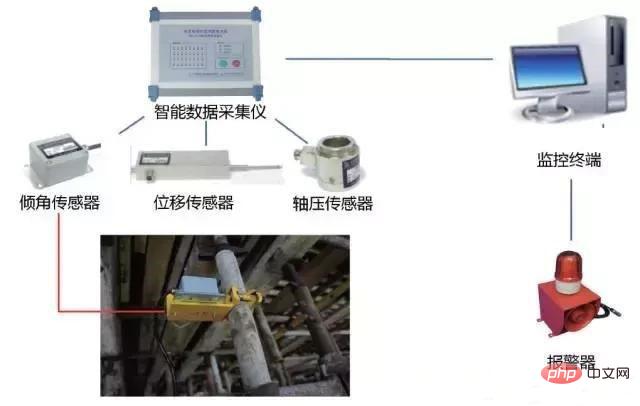

The tall formwork monitoring system consists of sensors, intelligent data collectors, alarms and monitoring software. It is used to monitor the formwork settlement, bracket deformation and pole axial force of the tall formwork support system in real time to achieve high support formwork construction. Safe real-time monitoring, over-limit warning and danger alarm functions.

The operating environment of this tutorial: Windows 7 system, Dell G3 computer.

Tall formwork monitoring system

The tall formwork monitoring system consists of sensors, intelligent data collectors, alarms and monitoring software for real-time Monitor the formwork settlement, bracket deformation and pole axial force of the tall formwork support system to achieve real-time monitoring, over-limit early warning and danger alarm functions for the safety of high-support formwork construction.

By comprehensively utilizing various Internet of Things technologies to connect on-site monitoring instruments, real-time monitoring of formwork settlement, bracket deformation and pole axial force of tall formwork support systems can be achieved, and real-time monitoring and over-limit early warning can be achieved , monitoring target of danger alarm. Realize the automatic collection of monitoring data (pressure, displacement, inclination, etc. data) and transmit it in real time through 3G and GPRS wireless networks to ensure the authenticity, integrity and timeliness of the monitoring data.

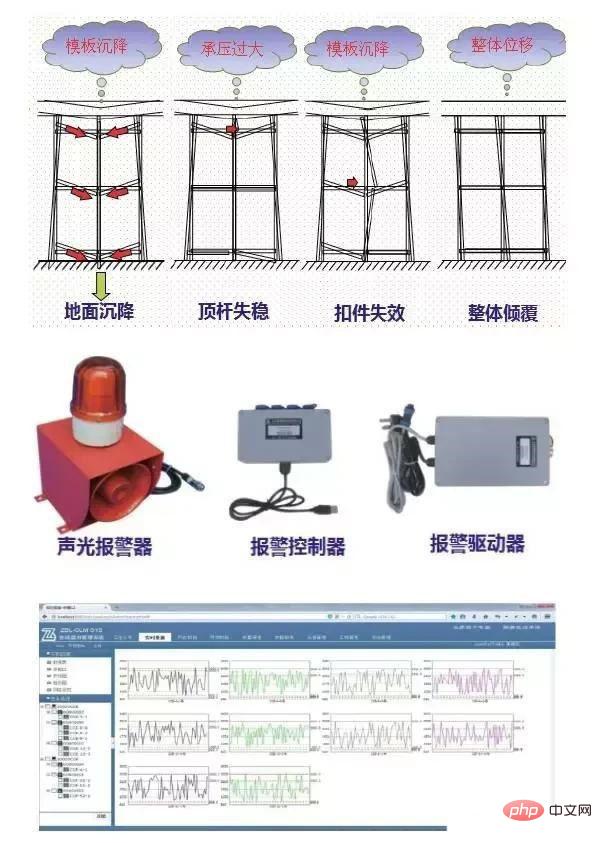

Through real-time monitoring of the formwork settlement, bracket deformation and pole axial force of the tall formwork support system, the monitoring goals of real-time monitoring, over-limit early warning, and danger alarm can be achieved. Using high-precision sensors and automatic acquisition instruments, the latest data can be read within one second. In addition to being able to sense the peripheral conditions of high-support molds, the use of sensors can easily monitor changes in the mold support system and improve the level of monitoring. High-end mold real-time monitoring and alarm system, innovative use of sound and light alarms. When the monitoring value exceeds the warning value, construction workers can read the warning signal from the machine during operation. The monitoring unit eliminates adverse factors that affect safety by promptly notifying the on-site project leader and supervisors; the alarm installed on the site will sound an alarm, and the on-site workers will stop construction, evacuate quickly, and notify the on-site project leader, project director and Safety supervisor.

Function

-

Automatic monitoring

can monitor the formwork settlement and vertical pole in real time Axial force, horizontal rod inclination angle, etc. are measured. The alarm threshold of each parameter can be set according to the design.

-

On-site alarm

Equipped with an alarm, it will automatically alarm when the monitoring value exceeds the threshold. It supports on-site sound and light alarm, SMS alarm and other alarm methods.

-

Data Curve

Real-time data is recorded throughout the entire process, data changes are dynamically displayed through curve graphs, and historical records are traceable.

Features

-

32 acquisition channels

Supports three types of sensors: displacement, inclination, and axial pressure.

-

High acquisition rate

The sampling frequency of each channel can reach 1Hz-10Hz; supports industrial-grade bus acquisition, and the reliable signal transmission distance can reach more than 1 kilometers.

-

High protection level

Fully protected acquisition link, IP65 protection level sensor and waterproof connector.

For more related knowledge, please visit the FAQ column!

The above is the detailed content of What does the tall formwork monitoring system consist of?. For more information, please follow other related articles on the PHP Chinese website!

Related articles

See more- What system is Huawei nova10?

- What is the compilation command of linux system

- There are several categories of equipment in the Linux system

- What is the difference between a pirated system and a genuine system?

- What should I do if windows boot manager cannot enter the system?

- What are the manufacturers of mes systems?