Detailed explanation of the air-conditioning assembly line work. The air-conditioning assembly line is a job that requires patience and meticulousness. It involves using various tools and machines to assemble and test air conditioning components. This job requires both physical strength and concentration. This job may be suitable for those who like to work with their hands and pay attention to details. In this article, php editor Banana will delve into all aspects of air-conditioning assembly line work, including responsibilities, skill requirements, work environment, and career prospects.

Is the air conditioning assembly line easy to make?

It’s not easy to do.

I once did it at Gree Air Conditioning Electronics Factory. I also did it at Midea Air Conditioning Electronics Factory. Including Haier Refrigerator Factory, etc. Working on an assembly line is definitely a busy job, and your hand speed must be fast otherwise you won't be able to keep up with others. It doesn't have much technical content, and it's not difficult to learn, but it's quite tedious. After a long time, most people can’t stand it!

Does the assembly line need people?

want. Generally, assembly lines have a large flow of people. There is no fixed number of people either. The recruitment volume is large

How to assemble chains on the assembly line of a shoe factory?

Chain assembly in shoe factory assembly lines is a complex process involving multiple steps and components. The following are the general assembly steps:

1. Prepare tools and materials: Make sure you have all the tools you need, such as screwdrivers, wrenches, chain links, sprockets, chain tensioners, etc. Additionally, make sure you have the correct chain model and specifications to match your assembly line equipment.

2. Check the existing chain: Before starting assembly, check the existing chain for wear, damage, or looseness. If you notice problems, you may need to replace the chain.

3. Install the sprockets: Install the sprockets on the shaft of the assembly line, making sure they are properly aligned and fixed in place. Use a wrench to tighten the bolts on the sprocket.

4. Measure and cut the chain: According to the length of the assembly line and the spacing of the sprockets, measure the required chain length. Use a chain cutter to cut the chain to the desired length.

5. Connect the chain: Connect the two ends of the chain together to form a ring. This usually involves inserting a special connecting piece, such as a link pin or quick coupler, into the end of the chain. Make sure the connection is tight and the chain is running smoothly.

6. Install the chain tensioner: Install the chain tensioner according to the manufacturer's recommendations. A chain tensioner helps maintain the correct tension on your chain, preventing it from loosening or skipping teeth.

7. Adjust the chain tension: Use the chain tensioner to adjust the chain tension to ensure that the chain runs smoothly on the sprocket and is not loose or overtight.

8. Inspection and Testing: After completing the assembly, check whether the chain is correctly installed on the sprocket and make sure the chain runs smoothly. Carry out a test run and observe the chain for any unusual noise, vibration or overheating.

Please note that the specific assembly steps may vary due to different shoe factory assembly lines and chain types. Therefore, before beginning assembly, be sure to carefully read the equipment's operating manual and service guide to ensure correct and safe operation. If necessary, please contact a professional service technician for assistance.

Is Eddie Precision Assembly an assembly line?

In the Aidi Precision Motor factory workshop, the robotic arm is on the assembly line, and the robot automated processing line is the first in the industry to realize unmanned automatic processing.

Electronics factory assembly line process?

They are all assembly lines, step by step, install one piece or several pieces at a time

What are the steps to install and assemble assembly line electrical sockets?

1. Clean the socket bottom box. The socket is installed after carpenters and painters, etc., and the bottom box that has been left for a long time will inevitably accumulate a lot of dust. During installation, first clean the bottom box of the switch socket, especially the dust and impurities in the box, and wipe away the remaining dust in the box with a damp cloth. This can prevent special impurities from affecting the use of the circuit.

2. Power cord handling. Leave the wires thrown out of the box for maintenance length, and then cut out the wire core, being careful not to damage the wire core. Wind the wire clockwise around the terminal corresponding to the switch or socket, and then tighten the indenter so that the core of the wire must not be exposed.

3. Three-wire socket wiring method. Connect the live wire to the A mark in one of the two holes of the switch, then take out the insulated wire from the other hole and connect it to the L hole in the three holes of the socket below. The neutral wire is directly connected to the N hole among the three holes of the socket and connected firmly. The ground wire is directly connected to the E hole among the three holes of the socket and connected firmly. If the neutral wire and the ground wire are incorrectly connected, tripping may occur when using electrical appliances.

4. Fixed installation of sockets. First, pass the wires thrown out of the box through the outlet holes of the plastic table, and then fasten the plastic table to the wall and fix it on the box with screws. After fixing, pass the wires through the wire holes of the switch socket according to their respective positions, and press the wires firmly according to the wiring requirements. Finally, attach the switch or socket to the plastic table, align it and fix it firmly with screws, and cover it with a decorative plate.

Are you tired of the assembly, packaging and testing assembly line?

very tired.

Working on the assembly line, everyone is fixed at a position and repeats the same actions every day. I feel like a robot. The only difference from a robot is that I can speak...

When I first started working, I worked in a factory on the assembly line for a year. I remember very well that the factory was making electronic scales. It was very large and there were many employees. There were more than a dozen assembly lines in one workshop. There were thirty or forty people, and everyone was working hard with their heads down. It was very uncomfortable on the first day when I went to work. I looked at the assembly line that was always conveying, and I had to work quickly on the assembly line

Is it tiring to assemble car rearview mirrors on the assembly line?

Generally speaking, it is not very tiring to assemble the car rearview mirror water line. Compared with the small line assembly in electronics factories, it takes less effort. But you must be familiar with and understand the skills of your work at work!

Are you tired of the refrigerator factory assembly line?

Not tired. The refrigerator factory assembly line is not tiring. Just click it into the component's slot. Just follow the work standards. It's just that the assembly line work is a little boring. The same kind of work is repeated every day. If you yearn for freedom, you may not be suitable for this job. Because the body is not tired at work. But I feel physically and mentally tired for a long time. Is the mobile phone factory assembled on an assembly line or on a piece-by-piece basis?

Hello...Mobile phone assembly is an assembly line...Electronic factories rarely offer piecework...Because electronics factories have many processes...piecework is not very cost-effective for you.. .Do you want to work in an electronics factory? The electronics factory is much easier than the machinery factory, but the salary is not as high as that of the machinery factory...Which factory to join mainly depends on what you think, the electronics factory does not have much technical content...it is quite good.

The above is the detailed content of Is it easy to build an air conditioner assembly line?. For more information, please follow other related articles on the PHP Chinese website!

Discover Survival Machine Save File Location & Protect FilesMay 08, 2025 pm 08:10 PM

Discover Survival Machine Save File Location & Protect FilesMay 08, 2025 pm 08:10 PMThis guide shows you where to find and how to protect your Survival Machine game save files. Knowing the save file location is crucial for managing your game, troubleshooting issues, or adjusting settings. Finding Your Survival Machine Save Files Fo

Effective Ways to Back up and Restore Windows CredentialsMay 08, 2025 pm 08:04 PM

Effective Ways to Back up and Restore Windows CredentialsMay 08, 2025 pm 08:04 PMThis guide explains how to back up and restore Windows credentials, a crucial system mechanism for secure authentication and credential storage. We'll cover what credentials are, how to safeguard them, and recovery methods. What Are Windows Credenti

Top 5 Proven Fixes for Sunderfolk out of Video MemoryMay 08, 2025 pm 08:02 PM

Top 5 Proven Fixes for Sunderfolk out of Video MemoryMay 08, 2025 pm 08:02 PMSolving Sunderfolk's Video Memory Issues: A Comprehensive Guide Sunderfolk, the engaging turn-based tactical RPG, can sometimes encounter video memory limitations. This guide provides solutions to resolve "Sunderfolk out of video memory" er

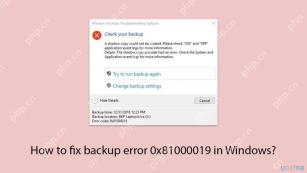

How to fix backup error 0x81000019 in Windows?May 08, 2025 pm 08:00 PM

How to fix backup error 0x81000019 in Windows?May 08, 2025 pm 08:00 PMWindows has a built-in backup program that allows people to create system images and restore points. During this, however, some people find themselves facing th

Among Us 3D Crashing/Not Launching: Check This Fresh GuideMay 08, 2025 pm 06:01 PM

Among Us 3D Crashing/Not Launching: Check This Fresh GuideMay 08, 2025 pm 06:01 PMAmong Us 3D PC version failed or crashed? MiniTool provides you with practical solutions! Many players encounter startup failure, crash, black screen or KWS issues when playing Among Us 3D PC version. This article will provide several ways to help you solve these problems and improve game performance. Quick navigation: How to fix the failure or crash of the Among Us 3D PC version Summarize Among Us 3D is a 3D version of the popular multiplayer Among Us, which combines elements of teamwork and betrayal. Many players reported crashes, black screens or stuck in the initial interface when the game started. Please follow the steps below to try to resolve the issue one by one. How to fix Among

NVIDIA OpenGL Driver Error Code 3 (Subcode 2/7), Quick Fix!May 07, 2025 pm 08:01 PM

NVIDIA OpenGL Driver Error Code 3 (Subcode 2/7), Quick Fix!May 07, 2025 pm 08:01 PMNVIDIA OpenGL driver error code 3: Game operation obstacles and solutions On Windows 11/10 systems, NVIDIA OpenGL driver error code 3 may cause the game to fail to run. This article will provide a variety of ways to resolve error code 3 (subcode 2 or 7). OpenGL is an industry-standard graphical application programming interface (API) for rendering 3D and 2D graphics. NVIDIA supports OpenGL for its GPU to perform at its best. However, NVIDIA OpenGL driver error code 3 interrupts all operations, causing the game and video/image editing software to be unusable. The error message may be as follows: NVI

How to fix Windows not booting after activating Secure Boot?May 07, 2025 pm 08:00 PM

How to fix Windows not booting after activating Secure Boot?May 07, 2025 pm 08:00 PMSecure Boot is a built-in security function of newer UEFI firmware that helps make sure only trusted, digitally signed operating systems and bootloaders can boo

How to Fix Failed to Load xgameruntime.dll Error Code 126May 06, 2025 pm 08:03 PM

How to Fix Failed to Load xgameruntime.dll Error Code 126May 06, 2025 pm 08:03 PMEncountering the "failed to load xgameruntime.dll error code 126"? This guide provides effective solutions to resolve this game launch issue. The xgameruntime.dll Error (Code 126): This error prevents certain games from launching, displayin

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

SublimeText3 English version

Recommended: Win version, supports code prompts!

Atom editor mac version download

The most popular open source editor

Notepad++7.3.1

Easy-to-use and free code editor

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.