Java

Java javaTutorial

javaTutorial What are the specific applications of Java functions in the manufacturing industry?

What are the specific applications of Java functions in the manufacturing industry?Java functions provide automation and increased efficiency for the manufacturing industry through the following applications: Inventory Management: Real-time tracking, automatic allocation, and predictive optimization of inventory. Production Planning: Dynamically assign production plans, perform preventive maintenance, and monitor production performance. Quality Control: Automatically detect defects, analyze trends and generate reports. Supply Chain Management: Automate supplier management, optimize logistics and provide end-to-end visibility.

Specific applications of Java functions in the manufacturing industry

Java functions are a powerful tool that can provide Extensive automation and efficiency opportunities. Here are some examples of specific applications of Java functions in manufacturing:

Inventory Management

- Real-time inventory tracking: Java functions can be obtained from Get real-time inventory data from multiple sources (e.g. ERP systems, IoT sensors, production lines) and aggregate it into one zentralen location.

- Automatic inventory allocation: Functions can automatically allocate inventory to orders, production plans and other activities based on predefined rules.

- Predictive Inventory Optimization: Functions can use machine learning techniques to analyze historical data, predict future demand and optimize inventory levels.

Production plan

- Dynamic production plan: Java function can monitor production data in real time and use optimization algorithms to adjust the order according to the order Adjust production plans with available resources.

- Preventive Maintenance Planning: Functions can analyze equipment sensor data, predict maintenance needs and automatically plan maintenance tasks.

- Production Performance Monitoring: Functions can provide real-time insights into bottlenecks, efficiency, and other key performance indicators by collecting and analyzing production data.

Quality Control

- Automatic defect detection: Java functions can integrate computer vision and machine learning techniques to inspect production lines defects and improve product quality.

- Data Analysis and Defect Trends: Functions can analyze defect data, identify trends and help identify quality improvement opportunities.

- Quality reports and dashboards: The function can automatically generate quality reports and dashboards so that managers can quickly understand production quality.

Supply Chain Management

- Supplier Management: Java functions to automate supplier evaluation, procurement process and delivery tracking .

- Logistics optimization: The function can use algorithms to optimize transportation routes and schedules to improve logistics efficiency.

- Supply Chain Visibility: Functions can integrate data from disparate sources into a unified view, providing end-to-end supply chain visibility.

Practical Case

Inventory Management in a Manufacturing Factory

A manufacturing factory implemented a Java function, This function integrates data from warehouses, production lines and suppliers into a zentralen database. The function tracks all inventory items in real time and uses machine learning to predict future demand. Through this system, the factory is able to keep inventory at lower levels while ensuring that all orders are filled.

The potential of Java functions in manufacturing is huge. By providing automation, insights and optimization, they help manufacturers increase efficiency, reduce costs and improve quality.

The above is the detailed content of What are the specific applications of Java functions in the manufacturing industry?. For more information, please follow other related articles on the PHP Chinese website!

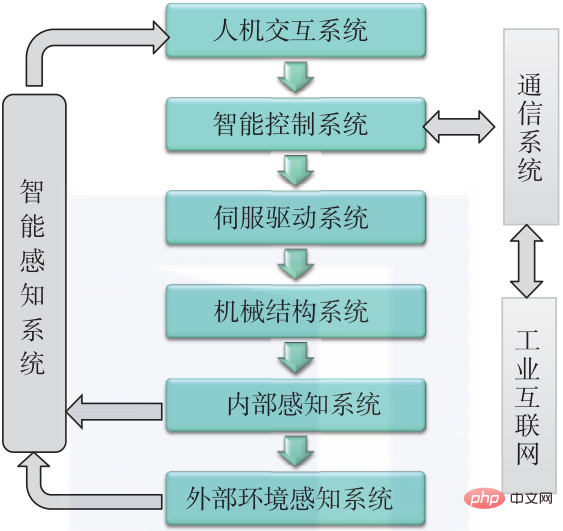

重要的制造业趋势:智能机器人需要具备四种能力Apr 24, 2023 pm 06:07 PM

重要的制造业趋势:智能机器人需要具备四种能力Apr 24, 2023 pm 06:07 PM智能机器人是智能产品的典型代表。智能机器人至少要具备以下三个要素:一是感知要素,用来认识周围环境状态;二是运动要素,对外界做出反应性动作;三是思考要素,根据感知要素所得到的信息,思考采用什么样的动作。人们通常把机器人划分为三代。第一代是可编程机器人,这种机器人一般可以根据操作人员所编的程序,完成一些简单的重复性操作。这一代机器人是从20世纪60年代后半叶开始投入使用的,目前在工业界已得到广泛应用。第二代是感知机器人,又叫作自适应机器人,它是在第一代机器人的基础上发展起来的,具有不同程度的感知周围

带你搞懂Java结构化数据处理开源库SPLMay 24, 2022 pm 01:34 PM

带你搞懂Java结构化数据处理开源库SPLMay 24, 2022 pm 01:34 PM本篇文章给大家带来了关于java的相关知识,其中主要介绍了关于结构化数据处理开源库SPL的相关问题,下面就一起来看一下java下理想的结构化数据处理类库,希望对大家有帮助。

一起聊聊Java多线程之线程安全问题Apr 21, 2022 pm 06:17 PM

一起聊聊Java多线程之线程安全问题Apr 21, 2022 pm 06:17 PM本篇文章给大家带来了关于java的相关知识,其中主要介绍了关于多线程的相关问题,包括了线程安装、线程加锁与线程不安全的原因、线程安全的标准类等等内容,希望对大家有帮助。

Java基础归纳之枚举May 26, 2022 am 11:50 AM

Java基础归纳之枚举May 26, 2022 am 11:50 AM本篇文章给大家带来了关于java的相关知识,其中主要介绍了关于枚举的相关问题,包括了枚举的基本操作、集合类对枚举的支持等等内容,下面一起来看一下,希望对大家有帮助。

详细解析Java的this和super关键字Apr 30, 2022 am 09:00 AM

详细解析Java的this和super关键字Apr 30, 2022 am 09:00 AM本篇文章给大家带来了关于Java的相关知识,其中主要介绍了关于关键字中this和super的相关问题,以及他们的一些区别,下面一起来看一下,希望对大家有帮助。

java中封装是什么May 16, 2019 pm 06:08 PM

java中封装是什么May 16, 2019 pm 06:08 PM封装是一种信息隐藏技术,是指一种将抽象性函式接口的实现细节部分包装、隐藏起来的方法;封装可以被认为是一个保护屏障,防止指定类的代码和数据被外部类定义的代码随机访问。封装可以通过关键字private,protected和public实现。

Java数据结构之AVL树详解Jun 01, 2022 am 11:39 AM

Java数据结构之AVL树详解Jun 01, 2022 am 11:39 AM本篇文章给大家带来了关于java的相关知识,其中主要介绍了关于平衡二叉树(AVL树)的相关知识,AVL树本质上是带了平衡功能的二叉查找树,下面一起来看一下,希望对大家有帮助。

归纳整理JAVA装饰器模式(实例详解)May 05, 2022 pm 06:48 PM

归纳整理JAVA装饰器模式(实例详解)May 05, 2022 pm 06:48 PM本篇文章给大家带来了关于java的相关知识,其中主要介绍了关于设计模式的相关问题,主要将装饰器模式的相关内容,指在不改变现有对象结构的情况下,动态地给该对象增加一些职责的模式,希望对大家有帮助。

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

VSCode Windows 64-bit Download

A free and powerful IDE editor launched by Microsoft

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

SublimeText3 Chinese version

Chinese version, very easy to use