Home >Hardware Tutorial >Hardware News >Highly flexible second-generation flat wire stator mass production line officially launched

Highly flexible second-generation flat wire stator mass production line officially launched

- WBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBforward

- 2024-04-07 13:50:14628browse

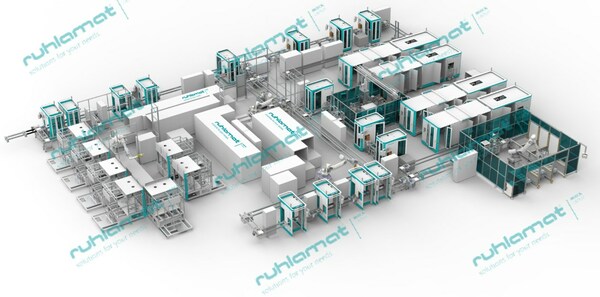

Suzhou, April 3, 2024 /PRNewswire/ -- After a year of careful research and development, the highly flexible second-generation flat wire stator mass production line was officially launched on April 2, with the industry's first wire forming process single station. The second-generation line has the following characteristics:

Features

The second-generation flat wire stator mass production line has high flexibility and adopts modular design. 50% of the process stations can be quickly Automatic type change, the entire line change time is less than 45 minutes. At the same time, we have upgraded and iterated process stations such as PIN molding, patent leather removal, automatic basket weaving, automatic PIN insertion, and welding, thereby achieving a significant increase in the OEE and automation rate of the entire line. The production cycle can be as fast as 30 seconds, which satisfies customers' demands for high The twin demands of efficiency and high quality.

Second generation flat wire stator mass production line

For the core process of wire forming, the second generation flat wire stator mass production line adopts a completely innovative design, the first in the industry .

High flexibility: Innovative 2D/3D molding mode, no need to change hardware, through software changeover, a single piece of equipment can meet the production of all linear shapes of a single stator. The straightening, patent leather removal, 2D, 3D, and pre-insertion processes are integrated into one process station. Solutions can be freely combined according to customer production capacity needs to achieve a flexible production model and reserve interfaces for future production expansion.

Save 2-3% copper wire: non-destructive cutting process blessing

Save 7.2 million yuan in copper wire cost: calculated based on annual production capacity of 600,000 yuan

Single station of wire forming process

Mr. Liang Chao, executive vice president of Rulamat (Suzhou) and CEO/director of Rulamat Huarui (Changzhou), said at the press conference: "I am very happy to witness Rulamat with everyone. Huarui (Changzhou) has taken a solid step in the field of new energy vehicle manufacturing. The second-generation flat wire stator mass production line was officially launched today. This is the crystallization of our long-term technological innovation and R&D investment, and it is also a symbol of our commitment to the new energy vehicle industry. Profound insights and positive responses to future development trends."

Mr. Liang Chao, Executive Vice President of Rulamat (Suzhou) and CEO/Director of Rulamat Huarui (Changzhou), delivered a speech

Subsequently, the guests visited the second-generation flat wire stator mass production line under the guidance of the instructors.

Factory Tour

In the future, Rulamat Huarui (Changzhou) will continue to maintain a rigorous attitude, insist on innovation and continuous progress, and work with customers to develop new technologies and new technologies. technology, injecting new impetus into the development of the new energy automobile industry chain and helping the global automobile industry achieve a more intelligent and green future. Detailed introduction to the second-generation flat wire stator mass production line will be released in the future. Please stay tuned to Ruramat Huarui (Changzhou) and look forward to sharing more exciting content with you!

The above is the detailed content of Highly flexible second-generation flat wire stator mass production line officially launched. For more information, please follow other related articles on the PHP Chinese website!

Related articles

See more- Similarities and Differences between Baselis Snake x Speed Edition and Ultimate Edition

- Why can't I buy mine cards? Details

- Comparing Razer Sano Tarantula and Dalyou DK100, which one is better?

- The 8th generation flagship mobile phone in 2019, you definitely can't miss it!

- Will the smartphone market usher in a cloud service revolution?