Technology peripherals

Technology peripherals AI

AI Everything we need to know about digital twins for manufacturing applications

Everything we need to know about digital twins for manufacturing applicationsEverything we need to know about digital twins for manufacturing applications

In the field of intelligent manufacturing, AI-driven digital twins have become a key technology. A digital twin is a digital model or replica of a real-world system that simulates a physical object or system in real time by using data from sensors and Internet of Things (IoT) devices to provide a digital representation. But in real applications, people Understanding of digital twins is often mixed. The following are some common misunderstandings:

The digital model (3D model of the object) established during the design phase to perform simulation is not a digital twin. During the design phase, it is valuable to explore various design options in simulation, but digital models represent idealized conditions rather than actual physical system conditions.- Models created through the reverse engineering process (also known as "digital shadows") are also not digital twins because they cannot affect the physical system.

- Unlike the above examples, digital twins use sensor data to keep the model continuously updated to reflect the current state of the physical system. Information flows from the physical system to the digital twin and vice versa. This two-way flow of information is the core difference between digital twins and traditional digital models.

Digital twins have the following characteristics in helping real-world manufacturing:

Quantified uncertainty: As long as sensors are involved, there is bound to be uncertainty in the state of the target system. No informed decision can be made without taking this uncertainty into account. Digital twins should have the ability to quantify uncertainty to ensure that they provide recommendations with an appropriate level of confidence.- Behavior and Performance Prediction : The digital twin should be able to predict future behavior or performance based on the current state of the system. This requires the digital twin to perform simulations in real time to evaluate different events that may occur in the future, their associated impacts and account for uncertainty in the system state.

- Monitoring physical systems : The digital twin should be able to monitor the performance of the physical manufacturing system in real time and provide actionable information to the controller overseeing the process.

- How does digital twin play a role in manufacturing?

After clarifying the concept of digital twins, we next need to understand the application of this technology in manufacturing

Digital twins provide information for task planners and schedulers, to make decisions based on the state of the manufacturing system.- Digital twins monitor the status and performance of machines and equipment in real time and predict when maintenance is needed.

- Digital twins identify defects and perform real-time quality control.

- When a system enters an error state, a digital twin can be used to diagnose the problem and recommend necessary recovery actions.

- By analyzing process data, digital twins can identify areas that need optimization or improvement.

- Digital twins can provide detailed records of processing or operating conditions to ensure compliance with relevant regulations.

- Digital twins can optimize manufacturing operations in real time to support on-demand production of personalized products.

- How does AI technology affect digital twins?

Over time, artificial intelligence technology has become more and more widely used to enhance the functionality of digital twins. Here are some important trends to watch

Sensors in robotic surface finishing cells can be used to build part models, replacing expensive traditional part-specific equipment in a customizable way. To eliminate the possibility of accidental collisions, tool paths need to take into account the uncertainty of the part model created by the sensor, which requires the power of AI.- Robots that perform surface finishing often require hoses and cables attached to the tool, but these attachments can limit the robot's movement. The digital twin can build a model of all the peripherals that need to be installed for the robot. With the help of AI, the system can estimate the actual status and predict the possible activity restrictions of the robot based on the peripherals connected to the robot.

- Digital twins can use AI-based prediction and health status management to ensure that adverse events are automatically detected. For example, a digital twin can use mechanics and vision data to determine the cause of rapid tool wear during robotic finishing and take corrective action to prevent it from happening again.

- How can organizations successfully deploy digital twin technology?

While the benefits of digital twins are clear, there are a series of steps that manufacturing organizations must take to successfully deploy digital twins. The following are several real-life issues that organizations may face:

- Data quality: Sensors generate large amounts of data to support digital twins. Organizations must take appropriate steps to ensure sensors reliably generate accurate data. AI tools can denoise the data and ensure it is provided in the correct format.

- Integrated scalable system: System integration is an important part of deploying digital twins. The underlying technology is changing rapidly, and new data streams are constantly being added. A scalable systems integration process ensures that system integration does not become a bottleneck. A modular approach with appropriate middleware is required to achieve scalable solutions.

- Powerful computing infrastructure: Digital twins need to rely on powerful computing power to process data, so it is necessary to obtain a powerful computing infrastructure with sufficient capacity and redundant resources.

- WORKFORCE: Implementing digital twins requires a workforce with unique skills, which requires upskilling existing employees and leveraging the services of solution providers.

- Long-term sustainability: Digital twins require regular maintenance and upgrades to ensure they continue to generate accurate predictions. Organizations should formulate long-term sustainable development plans to ensure the good and healthy development of digital twins. Subscription models for solution providers will also become an important tool in avoiding unexpected incidents.

- Cybersecurity and Privacy Issues: Increased connectivity will increase cybersecurity risks. The storage and use of data may also raise privacy concerns. Addressing these issues requires implementing the latest cybersecurity measures. In addition, ensuring regulatory compliance on privacy issues may require data encryption and regular security audits.

Manufacturing organizations need to develop an overall plan to address the above issues as they attempt to deploy digital twins. Once successfully implemented, this technology will effectively reduce costs, reduce failures, improve quality and performance, and help companies actively embrace the new era of intelligent manufacturing

The above is the detailed content of Everything we need to know about digital twins for manufacturing applications. For more information, please follow other related articles on the PHP Chinese website!

Tool Calling in LLMsApr 14, 2025 am 11:28 AM

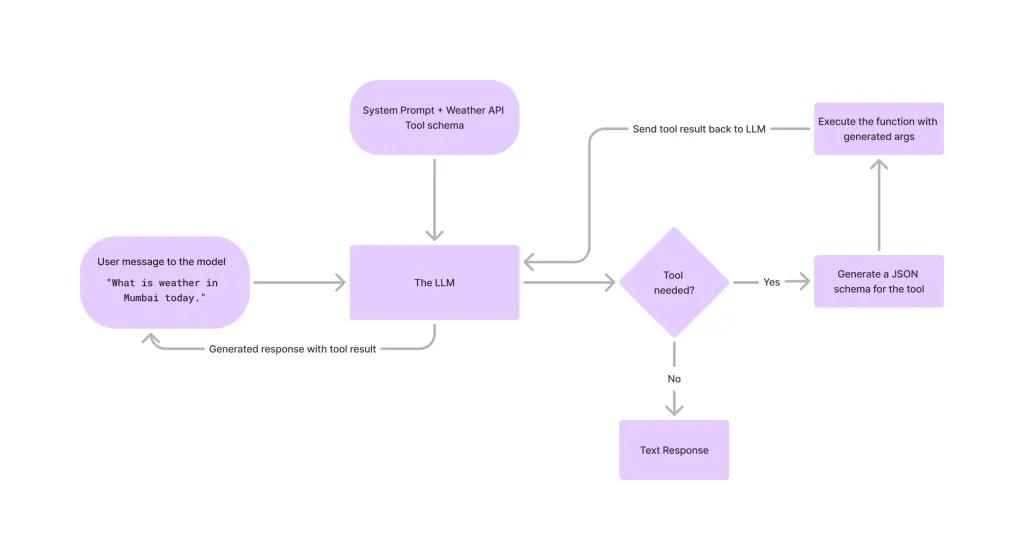

Tool Calling in LLMsApr 14, 2025 am 11:28 AMLarge language models (LLMs) have surged in popularity, with the tool-calling feature dramatically expanding their capabilities beyond simple text generation. Now, LLMs can handle complex automation tasks such as dynamic UI creation and autonomous a

How ADHD Games, Health Tools & AI Chatbots Are Transforming Global HealthApr 14, 2025 am 11:27 AM

How ADHD Games, Health Tools & AI Chatbots Are Transforming Global HealthApr 14, 2025 am 11:27 AMCan a video game ease anxiety, build focus, or support a child with ADHD? As healthcare challenges surge globally — especially among youth — innovators are turning to an unlikely tool: video games. Now one of the world’s largest entertainment indus

UN Input On AI: Winners, Losers, And OpportunitiesApr 14, 2025 am 11:25 AM

UN Input On AI: Winners, Losers, And OpportunitiesApr 14, 2025 am 11:25 AM“History has shown that while technological progress drives economic growth, it does not on its own ensure equitable income distribution or promote inclusive human development,” writes Rebeca Grynspan, Secretary-General of UNCTAD, in the preamble.

Learning Negotiation Skills Via Generative AIApr 14, 2025 am 11:23 AM

Learning Negotiation Skills Via Generative AIApr 14, 2025 am 11:23 AMEasy-peasy, use generative AI as your negotiation tutor and sparring partner. Let’s talk about it. This analysis of an innovative AI breakthrough is part of my ongoing Forbes column coverage on the latest in AI, including identifying and explaining

TED Reveals From OpenAI, Google, Meta Heads To Court, Selfie With MyselfApr 14, 2025 am 11:22 AM

TED Reveals From OpenAI, Google, Meta Heads To Court, Selfie With MyselfApr 14, 2025 am 11:22 AMThe TED2025 Conference, held in Vancouver, wrapped its 36th edition yesterday, April 11. It featured 80 speakers from more than 60 countries, including Sam Altman, Eric Schmidt, and Palmer Luckey. TED’s theme, “humanity reimagined,” was tailor made

Joseph Stiglitz Warns Of The Looming Inequality Amid AI Monopoly PowerApr 14, 2025 am 11:21 AM

Joseph Stiglitz Warns Of The Looming Inequality Amid AI Monopoly PowerApr 14, 2025 am 11:21 AMJoseph Stiglitz is renowned economist and recipient of the Nobel Prize in Economics in 2001. Stiglitz posits that AI can worsen existing inequalities and consolidated power in the hands of a few dominant corporations, ultimately undermining economic

What is Graph Database?Apr 14, 2025 am 11:19 AM

What is Graph Database?Apr 14, 2025 am 11:19 AMGraph Databases: Revolutionizing Data Management Through Relationships As data expands and its characteristics evolve across various fields, graph databases are emerging as transformative solutions for managing interconnected data. Unlike traditional

LLM Routing: Strategies, Techniques, and Python ImplementationApr 14, 2025 am 11:14 AM

LLM Routing: Strategies, Techniques, and Python ImplementationApr 14, 2025 am 11:14 AMLarge Language Model (LLM) Routing: Optimizing Performance Through Intelligent Task Distribution The rapidly evolving landscape of LLMs presents a diverse range of models, each with unique strengths and weaknesses. Some excel at creative content gen

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

Atom editor mac version download

The most popular open source editor

SublimeText3 Linux new version

SublimeText3 Linux latest version

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),