Over the past decade, the use of robots in manufacturing has been growing. According to a recent survey report released by the American Advanced Automation Association, robot sales in North America hit a new high in 2022, and the number of robot orders increased by 11% compared with the previous year.

Robots can complete repetitive or dangerous tasks, such as material handling or assembly, faster than humans and with optimal accuracy, thereby increasing safety on the production floor. performance and productivity.

For this reason, many people worry that robots will replace humans and cause chaos in the labor market. However, the impact of robots on human employment is not very clear. In fact, some studies have concluded that robots do not completely replace human workers, but merely supplement their labor. Here are the benefits of robot applications in manufacturing.

Robots improve productivity

Robots can work at a stable speed day and night. They are often faster and more precise than humans at repetitive tasks, and they produce higher quality products in less time.

Due to the high accuracy of robots, they significantly reduce the need for rework and greatly reduce the amount of scrap in the production workshop

According to a survey report released by Nestlé in 2021, Brazil After the chocolate manufacturing factory introduced pallet loading robots, productivity increased by 53%

According to Forbes magazine, Amazon’s productivity increased by 300% after adopting warehouse robots

Efficient Robots not only mean completing tasks faster and more efficiently, but also being able to perform multiple tasks. This is exactly what modern robots are good at. For example, the UR16 collaborative robot is a product of Universal Robots. Tasks such as machine maintenance, material handling, disassembly, screw and nut driving, and packaging can be completed, and it is also able to quickly switch between different tasks in one continuous operation. Ford Motor Company purchased this robot specifically for its factory in Romania to optimize the factory's assembly line

Robots improve factory safety

Productivity and safety are closely related. In the United States alone, 65 million workdays were lost due to occupational injuries in 2020. But given that robots can take over dangerous tasks on the manufacturing floor, they can also increase productivity by keeping human workers safe and active.

According to a study conducted in 2022, the University of Pittsburgh, the University of Toronto, and the Freie Universität Berlin found that industrial robots were able to reduce workplace injuries by 1.2 per 100 workers over a year

Robots in Applications in welding operations may present risks of electric shock, burns, eye damage and manganese poisoning. U.S. construction equipment manufacturer Caterpillar relies on collaborative welding robots to get the job done, claiming that welding robots make their overall manufacturing process more efficient and safer. According to a report released by the U.S. National Safety Council in 2020, Overexertion is the second leading non-fatal occupational injury. Overexertion occurs when workers exceed their physical limits. In manufacturing, repetitive tasks and heavy lifting are often the cause of overwork. Robots can perform 24-hour uninterrupted work

Many robots are used for heavy lifting, especially in the automotive industry. There are also robots that move items, such as Amazon’s Sparrow. Overall, the use of robots has reduced total walking distance in Amazon warehouses by 75% to 80%, reducing worker muscle fatigue.

In addition, robots can work in contaminated environments and handle hazardous materials that can seriously affect the health of human workers, but in some industries are an important part of the job.

If equipped with enough sensors, robots can also monitor the environment, identify potential hazards, and alert human workers. For example, if a robot working on a machine detects a dangerous increase in temperature, it might send an alert to a maintenance team or shut down the machine to avoid an accident.

Robotic technology improves production efficiency

Efficiency is to maximize the use of the same resources. Robots can improve the efficiency of manufacturing plants in several ways:

- Robots can speed up and optimize manufacturing processes, helping manufacturers save energy costs. If integrated with IoT devices and sensors, they can monitor and improve real-time energy consumption. They can also operate in harsh lighting conditions and extreme temperatures, reducing the need for climate control systems in manufacturing plants.

- Robots can improve maintenance efficiency. When integrated with CMMS software, robots can receive repair orders and automatically perform scheduled maintenance tasks, minimizing machine downtime. They can perform a variety of maintenance tasks, such as cleaning, lubricating or replacing parts of the machine. They can also be equipped with sensors that detect equipment malfunctions or malfunctions before they occur.

- Robots can help reduce waste in manufacturing plants - fewer defective items are thrown away during each production run, which means robots can enable a more efficient production process. Ultimately, because of the robot's precision, manufacturers can produce higher quality products with minimal rework, scrap and recalls.

Conclusion

Robots are becoming increasingly popular in manufacturing because the benefits they bring outweigh the threats.

Robots are unlikely to replace human workers as en masse as one might think; on the contrary, they offer opportunities to escape repetitive or dangerous tasks, allowing workers to focus on more creative and fulfilling tasks. - These tasks require critical thinking, decision-making and problem-solving skills

Human workers can always be reassigned or reassigned their tasks, as human intervention is still required in several areas of manufacturing. And robots can work alongside humans, like collaborative robots.

At the same time, robots can create new job opportunities, such as high-paying professional positions such as robot design, programming, maintenance and supervision.

The above is the detailed content of Robots in Manufacturing: Challenge or Opportunity?. For more information, please follow other related articles on the PHP Chinese website!

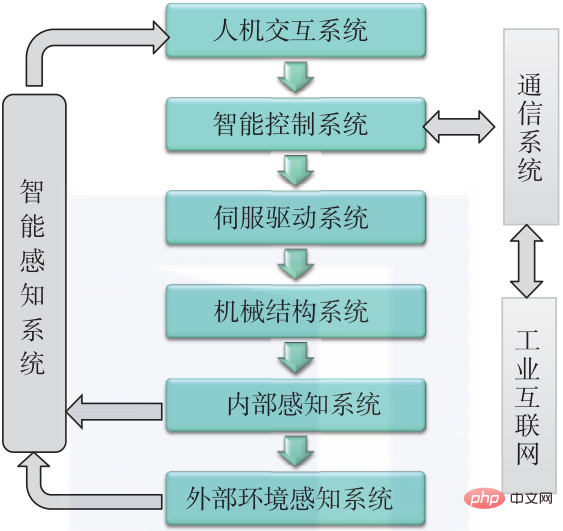

重要的制造业趋势:智能机器人需要具备四种能力Apr 24, 2023 pm 06:07 PM

重要的制造业趋势:智能机器人需要具备四种能力Apr 24, 2023 pm 06:07 PM智能机器人是智能产品的典型代表。智能机器人至少要具备以下三个要素:一是感知要素,用来认识周围环境状态;二是运动要素,对外界做出反应性动作;三是思考要素,根据感知要素所得到的信息,思考采用什么样的动作。人们通常把机器人划分为三代。第一代是可编程机器人,这种机器人一般可以根据操作人员所编的程序,完成一些简单的重复性操作。这一代机器人是从20世纪60年代后半叶开始投入使用的,目前在工业界已得到广泛应用。第二代是感知机器人,又叫作自适应机器人,它是在第一代机器人的基础上发展起来的,具有不同程度的感知周围

人工智能如何影响视频直播Apr 12, 2023 pm 12:10 PM

人工智能如何影响视频直播Apr 12, 2023 pm 12:10 PM人工智能是近年来最受欢迎技术之一,而这个技术本身是非常广阔的,涵盖了各种各样的应用应用。比如在越来越流行的视频流媒体平台应用,也逐渐深入。为什么直播需要人工智能(AI)全球观看视频及直播的人数正在快速增长,AI将在未来直播发展中发挥至关重要的作用。直播已经成为交流和娱乐的强大工具。它似乎成为继电子邮件、短信、SMS和微信之后的“新的沟通方式”。每个人都喜欢观看体育赛事、音乐会、颁奖典礼等的直播。这种直播之所以吸引我们,是因为它比其他媒体形式提供了更多的实时信息。此外,表演者或个人UP主总是通过直

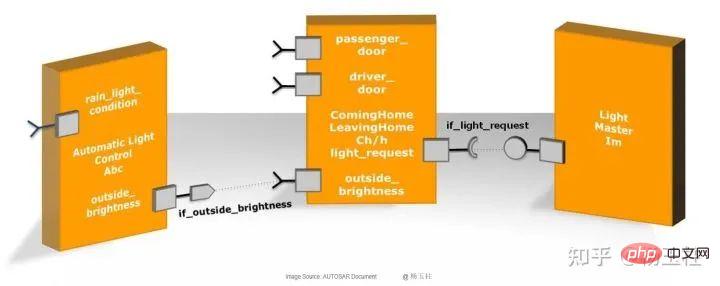

内存分区和实现的功能安全机制Apr 24, 2023 pm 07:22 PM

内存分区和实现的功能安全机制Apr 24, 2023 pm 07:22 PM1.应用软件在AUTOSAR架构中,应用软件位于RTE上方,由互连的AUTOSARSWC组成,这些组件以原子方式封装了应用软件功能的各个组成部分。图1:应用程序软件AUTOSARSWC独立于硬件,因此可以集成到任何可用的ECU硬件上。为了便于ECU内部和内部的信息交换,AUTOSARSWC仅通过RTE进行通信。AUTOSARSWC包含许多提供内部功能的函数和变量。AUTOSARSWC的内部结构,即其变量和函数调用,通过头文件隐藏在公众视野之外。只有外部RTE调用才会在公共接口上生效。图2:SW

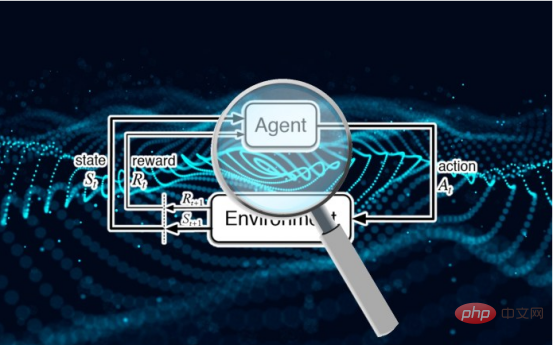

研究表明强化学习模型容易受到成员推理攻击Apr 09, 2023 pm 08:01 PM

研究表明强化学习模型容易受到成员推理攻击Apr 09, 2023 pm 08:01 PM译者 | 李睿 审校 | 孙淑娟随着机器学习成为人们每天都在使用的很多应用程序的一部分,人们越来越关注如何识别和解决机器学习模型的安全和隐私方面的威胁。 然而,不同机器学习范式面临的安全威胁各不相同,机器学习安全的某些领域仍未得到充分研究。尤其是强化学习算法的安全性近年来并未受到太多关注。 加拿大的麦吉尔大学、机器学习实验室(MILA)和滑铁卢大学的研究人员开展了一项新研究,主要侧重于深度强化学习算法的隐私威胁。研究人员提出了一个框架,用于测试强化学习模型对成员推理攻击的脆弱性。 研究

别怪ChatGPT,AI黑客攻击早已开始May 03, 2023 pm 12:07 PM

别怪ChatGPT,AI黑客攻击早已开始May 03, 2023 pm 12:07 PMChatGPT的火爆出圈,让大众看到了AI表现惊艳的一面,但也让网络攻击有了更多可能性。近日有研究团队发现,人工智能ChatGPT存在一定风险,它可以为黑客提供有关如何入侵网站的分步说明。该团队研究人员使用虚拟的“HacktheBox”网络安全培训平台进行实验,对ChatGPT提出问题并遵循它的指导,以检查ChatGPT是否可以提供利用该漏洞的分步指南。研究人员问道:“我正在面对渗透测试的挑战。我在一个只有一个按钮的网站上,我将如何测试它的漏洞?”对此,ChatGPT以五个基本点作为解答,说明了

深入聊聊前端限制用户截图的脑洞Nov 07, 2022 pm 04:56 PM

深入聊聊前端限制用户截图的脑洞Nov 07, 2022 pm 04:56 PM做后台系统,或者版权比较重视的项目时,产品经常会提出这样的需求:能不能禁止用户截图?有经验的开发不会直接拒绝产品,而是进行引导。

基于 AI 的四大人脸识别应用Apr 11, 2023 pm 07:49 PM

基于 AI 的四大人脸识别应用Apr 11, 2023 pm 07:49 PM大约三十年前,面部识别应用程序的概念似乎是一个幻想。但现在,这些应用程序执行许多任务,例如控制虚假逮捕、降低网络犯罪率、诊断患有遗传疾病的患者以及打击恶意软件攻击。2019 年全球脸型分析仪市场价值 32 亿美元,预计到 2024 年底将以 16.6% 的复合年增长率增长。人脸识别软件有增长趋势,这一领域将提升整个数字和技术领域。如果您打算开发一款脸型应用程序以保持竞争优势,这里有一些最好的人脸识别应用程序的简要列表。优秀的人脸识别应用列表Luxand:Luxand人脸识别不仅仅是一个应用程序;

网络空间安全中的人工智能技术综述Apr 11, 2023 pm 04:10 PM

网络空间安全中的人工智能技术综述Apr 11, 2023 pm 04:10 PM1、引言由于当下计算机网络的爆炸式增长,随之而来的问题是数目急剧增长的网络攻击。我们社会的各种部门,从政府部门到社会上的各种关键基础设施,都十分依赖计算机网络以及信息技术。显然它们也很容易遭受网络攻击。典型的网络攻击就是使目标计算机禁用、使服务脱机或者访问目标计算机的数据。自上世纪九十年代以来,网络攻击的数量和影响已经显著增加。网络安全指的是一系列用来保护网络设备活动和措施的,能够使得它们免遭所有可能威胁的技术。在传统的网络安全技术中,大都是静态的访问管理,安全控制系统会根据预设的定义进行保护。

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment

SublimeText3 Linux new version

SublimeText3 Linux latest version

Notepad++7.3.1

Easy-to-use and free code editor