Technology peripherals

Technology peripherals AI

AI Baotou Chemical Industry's first intelligent inspection robot 'takes office'

Baotou Chemical Industry's first intelligent inspection robot 'takes office'Baotou Chemical Industry's first intelligent inspection robot 'takes office'

Recently, the first intelligent inspection robot of Guoneng Baotou Coal Chemical Co., Ltd. was officially "on duty" to ensure the safe and stable operation of the equipment and lay a solid foundation for the realization of automation, modernization and intelligent development.

The system consists of intelligent inspection robots, mobile inspection devices, intelligent inspection management platforms, automatic charging piles, and mobile carrier control systems. The intelligent inspection robot body is equipped with advanced infrared thermal imaging temperature measurement, high-definition visible light camera, omnidirectional rotating pan-tilt and other sensors. The advanced infrared thermal imaging temperature measurement can detect the temperature of the equipment, analyze the temperature measurement value, and respond to abnormal situations. Timely alarm processing; high-definition visible light cameras and omnidirectional rotating pan/tilts can capture high-definition images of on-site meters in real time. Through digital image processing, pattern recognition detection and other methods, intelligent identification of various meters, switches, and status indicators can be realized. At the same time, it has functions such as directional collection of audio information from equipment, two-way voice intercom, automatic charging, automatic identification, and auxiliary lighting.

When the intelligent inspection robot is working, according to the production inspection requirements, it inspects 502 inspection points in the production area, collects and monitors data in real time, and realizes 24-hour uninterrupted automatic inspection of on-site equipment. Digital images are uploaded to the server and client. At the same time, operators conduct in-depth analysis and processing of the video, audio and alarms collected by the inspection robot to eliminate production safety hazards in a timely manner and provide a reliable basis for ensuring the safe operation of the company.

Through the implementation of the intelligent inspection robot system, it plays a positive role in ensuring the safe and stable operation of equipment and improving the level of intelligent management. It effectively improves the safety and reliability of equipment, while reducing the labor intensity of employees and improving work efficiency. quality and efficiency, and comprehensively improve production safety capabilities.

The content that needs to be rewritten is: (Zhang Xijun)

The above is the detailed content of Baotou Chemical Industry's first intelligent inspection robot 'takes office'. For more information, please follow other related articles on the PHP Chinese website!

Personal Hacking Will Be A Pretty Fierce BearMay 11, 2025 am 11:09 AM

Personal Hacking Will Be A Pretty Fierce BearMay 11, 2025 am 11:09 AMCyberattacks are evolving. Gone are the days of generic phishing emails. The future of cybercrime is hyper-personalized, leveraging readily available online data and AI to craft highly targeted attacks. Imagine a scammer who knows your job, your f

Pope Leo XIV Reveals How AI Influenced His Name ChoiceMay 11, 2025 am 11:07 AM

Pope Leo XIV Reveals How AI Influenced His Name ChoiceMay 11, 2025 am 11:07 AMIn his inaugural address to the College of Cardinals, Chicago-born Robert Francis Prevost, the newly elected Pope Leo XIV, discussed the influence of his namesake, Pope Leo XIII, whose papacy (1878-1903) coincided with the dawn of the automobile and

FastAPI-MCP Tutorial for Beginners and Experts - Analytics VidhyaMay 11, 2025 am 10:56 AM

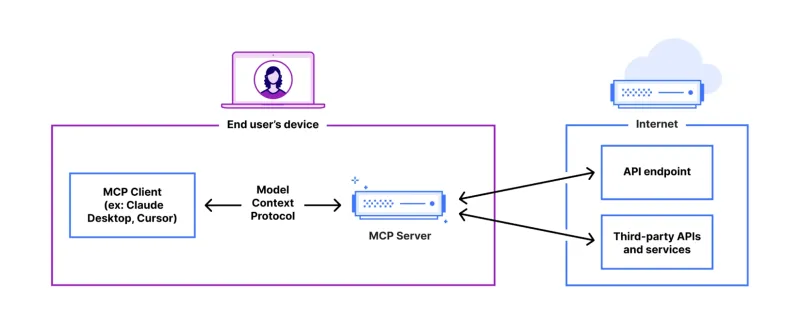

FastAPI-MCP Tutorial for Beginners and Experts - Analytics VidhyaMay 11, 2025 am 10:56 AMThis tutorial demonstrates how to integrate your Large Language Model (LLM) with external tools using the Model Context Protocol (MCP) and FastAPI. We'll build a simple web application using FastAPI and convert it into an MCP server, enabling your L

Dia-1.6B TTS : Best Text-to-Dialogue Generation Model - Analytics VidhyaMay 11, 2025 am 10:27 AM

Dia-1.6B TTS : Best Text-to-Dialogue Generation Model - Analytics VidhyaMay 11, 2025 am 10:27 AMExplore Dia-1.6B: A groundbreaking text-to-speech model developed by two undergraduates with zero funding! This 1.6 billion parameter model generates remarkably realistic speech, including nonverbal cues like laughter and sneezes. This article guide

3 Ways AI Can Make Mentorship More Meaningful Than EverMay 10, 2025 am 11:17 AM

3 Ways AI Can Make Mentorship More Meaningful Than EverMay 10, 2025 am 11:17 AMI wholeheartedly agree. My success is inextricably linked to the guidance of my mentors. Their insights, particularly regarding business management, formed the bedrock of my beliefs and practices. This experience underscores my commitment to mentor

AI Unearths New Potential In The Mining IndustryMay 10, 2025 am 11:16 AM

AI Unearths New Potential In The Mining IndustryMay 10, 2025 am 11:16 AMAI Enhanced Mining Equipment The mining operation environment is harsh and dangerous. Artificial intelligence systems help improve overall efficiency and security by removing humans from the most dangerous environments and enhancing human capabilities. Artificial intelligence is increasingly used to power autonomous trucks, drills and loaders used in mining operations. These AI-powered vehicles can operate accurately in hazardous environments, thereby increasing safety and productivity. Some companies have developed autonomous mining vehicles for large-scale mining operations. Equipment operating in challenging environments requires ongoing maintenance. However, maintenance can keep critical devices offline and consume resources. More precise maintenance means increased uptime for expensive and necessary equipment and significant cost savings. AI-driven

Why AI Agents Will Trigger The Biggest Workplace Revolution In 25 YearsMay 10, 2025 am 11:15 AM

Why AI Agents Will Trigger The Biggest Workplace Revolution In 25 YearsMay 10, 2025 am 11:15 AMMarc Benioff, Salesforce CEO, predicts a monumental workplace revolution driven by AI agents, a transformation already underway within Salesforce and its client base. He envisions a shift from traditional markets to a vastly larger market focused on

AI HR Is Going To Rock Our Worlds As AI Adoption SoarsMay 10, 2025 am 11:14 AM

AI HR Is Going To Rock Our Worlds As AI Adoption SoarsMay 10, 2025 am 11:14 AMThe Rise of AI in HR: Navigating a Workforce with Robot Colleagues The integration of AI into human resources (HR) is no longer a futuristic concept; it's rapidly becoming the new reality. This shift impacts both HR professionals and employees, dem

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

SublimeText3 Linux new version

SublimeText3 Linux latest version

WebStorm Mac version

Useful JavaScript development tools