Technology peripherals

Technology peripherals AI

AI Industrial robot application scenarios: Accelerate the rush of 'trendy makers' and help the industry improve quality and efficiency

Industrial robot application scenarios: Accelerate the rush of 'trendy makers' and help the industry improve quality and efficiencyIndustrial robot application scenarios: Accelerate the rush of 'trendy makers' and help the industry improve quality and efficiency

Not long ago, a news story happened in a hot pot restaurant in Chongqing, about the scene of a "robot" waiter toasting and pouring tea to customers. This news quickly aroused heated discussion on the Internet. These humanoid machines not only look lifelike, but also move very smoothly, making people feel like they are in a science fiction world, which is amazing

In fact, this "robot" was pretended to be a hip-hop dance boss, but unexpectedly it became popular on the Internet. Behind this hot search lies not only the store's ingenuity to attract business, but also the public's curiosity about robots and yearning for future technology. At the just-concluded Hangzhou Asian Games, a variety of robots were used to pick up balls, clean and navigate, ensuring the success of the event.

In industrial scenarios, robots have become an important force in improving industry quality and efficiency, showing amazing synergy effects. According to data from Tianyancha, there are currently more than 231,000 industrial robot-related companies in my country, of which more than 22,000 new registered companies will be added from January to October 2023 alone. Today, industrial robots have been widely used in various industrial fields such as electronics, logistics, chemicals, medical care, and automobiles

Against the background of the popularity of artificial intelligence technology and the popularity of contactless services, the development and application scenarios of industrial robots are even more worth looking forward to. Tianyancha Research Institute believes that under the guidance of the digital economy and the integration of digital and real, vigorously developing the industrial robot industry will effectively promote the transformation and upgrading of China's manufacturing structure and continue to enhance and maintain the competitiveness of Chinese manufacturing in the international market.

Competitive focus: critical infrastructure

Industrial robots are becoming a major trend.

Intelligent robots are known as "the crown jewel of the manufacturing industry". Their research and development, manufacturing and application are important indicators of a country's technological innovation and high-end manufacturing level. In the context of the new technological revolution and industrial transformation, major economies around the world are actively competing, and intelligent manufacturing, dominated by industrial robots, has become the focus of competition

In early 2023, the "Robots" Application Action Implementation Plan issued by the Ministry of Industry and Information Technology clearly stated that in the manufacturing field, "promote the construction of intelligent manufacturing demonstration factories and create typical application scenarios for industrial robots. Develop intelligent manufacturing systems based on industrial robots, Assisting the digital transformation and intelligent transformation of the manufacturing industry." This means that industrial robots, as critical infrastructure, are playing an increasingly important role.

Industrial robots are multi-joint manipulators or multi-degree-of-freedom machines and equipment widely used in the industrial field. They have certain automation capabilities and can use their own power and control capabilities to achieve various industrial processing and manufacturing functions. With the continuous development of robotics technology, the intelligent manufacturing model has become an important direction for industrial development and transformation, of which digitalization, networking and intelligence are its core features

Compared with traditional industrial equipment, industrial robots have many advantages, such as ease of use, high level of intelligence, high production efficiency and safety, easy management and significant economic benefits. The development of industrial robots can not only improve the quality and quantity of products, but is also very important for ensuring personal safety, improving the working environment, reducing labor intensity, improving labor productivity, saving material consumption and reducing production costs.

Driven by multiple factors such as intensive domestic policies and an increasingly mature market, industrial robots are growing rapidly, and scenario applications are also accelerating. According to data from Tianyancha, by 2022, my country's installed capacity of industrial robots will account for more than 50% of the world's total, ranking firmly as the world's largest market. The density of manufacturing robots will reach 392 units per 10,000 workers. In this year, the operating income of my country's robot industry exceeded 170 billion yuan, continuing to maintain double-digit growth

Implementation Application: Empowering Traditional Manufacturing

At the just-concluded Shanghai International Trade Fair, an arm robot capable of customizing lipstick attracted widespread attention

Generally speaking, it takes 1 hour for lipstick to go from canned to finished product, but this smart lipstick customization machine only takes 6 minutes. Users only need to give instructions through the screen, and the lipstick robot can capture the user's avatar and facial features in real time through the built-in 3D AR camera. With the independently developed AR facial tracking algorithm, the lipstick robot can present makeup, hair color and other makeup trial effects in real time. on the machine screen.

Not only are they trendy and fun, but they are also functional. Today’s industrial robots are bringing more imagination to the traditional Chinese manufacturing industry. Today, industrial robots are widely used in fields such as automated production, automobile manufacturing, logistics, 3C electronics, and medical care.

In the field of automated production, industrial robots are a vital piece of equipment. It can perform repetitive, tedious, dangerous or high-precision work, improving the production efficiency of enterprises. In addition, industrial robots have programmability and high-precision control technology, which can quickly respond to changing production needs and achieve rapid conversion of batch or small batch production

In the automobile manufacturing process, industrial robots can undertake a variety of tasks, including welding, painting, assembly and dispensing, thereby improving the efficiency of the production line and the quality of the product. In automobile parts manufacturing, industrial robots can also be used in various processes such as mold casting, milling and clamping, significantly improving production efficiency and yield rate

With the passage of time, industrial robots are becoming more and more widely used in the logistics industry. Its application range includes handling and classifying goods, warehousing management and transportation, etc., which can greatly improve logistics efficiency and safety. In addition, industrial robots can also help companies reduce personnel costs and reduce operational risks

In the manufacturing and packaging process of electronic products such as mobile phones, industrial robots are widely used in the 3C electronics industry. They have highly flexible movement and operation capabilities, enabling them to accurately perform complex assembly tasks and automate repetitive tasks. This automated approach effectively avoids the negative impact of manual errors on product quality

In the medical industry that pays attention to high precision and safety, industrial robots also have many applications. For example, it can be used for a variety of tasks including surgery, therapy, and rehabilitation. In addition, industrial robots can also help hospitals solve the problem of insufficient medical staff and provide patients with more diverse rehabilitation treatment options.

Prospects: Artificial intelligence accelerates the development of industrial robots

Looking around the world, the scale of the industrial robot industry is accelerating.

Marina Bill, President of the International Federation of Robotics, recently stated that the global industrial robot market is expected to grow by 7% in 2023, or more than 590,000 units. Among them, China is the largest market in the world. According to the "2023 World Robot Report", China's installation volume in 2022 will reach 290,258 units, a year-on-year increase of 5%, setting a new record in 2021. Since 2017, robot installations have grown at an average annual rate of 13%.

Domestic industrial robots have gradually increased their market share with their rapidly breakthrough product performance, more advantageous cost performance and service levels. Data from the National Bureau of Statistics show that the average import price of my country's industrial robot products has gradually dropped from 162,300/unit in 2019 to 85,200/unit in 2022. Generally, the price of domestic robots is lower than that of imported robots.

Behind the rapid growth of the domestic industrial robot market, relevant policies to encourage industrial development have been introduced one after another. "Made in China 2025" sets goals for the development of domestic industrial robots and puts forward clear requirements for the localization rate of domestic robots and key components. In order to better support the development of industrial robots in my country, industry companies are also gradually achieving technological breakthroughs and improving the localization level of industrial robots.

Currently, artificial intelligence is becoming the "brain" of industrial robots. Machine learning algorithms enable robots to make decisions to adapt to changing environments. It has been pointed out that artificial intelligence has huge potential in robotics and can bring a range of benefits to the manufacturing industry, such as process optimization, predictive maintenance or vision-based gripping

This means that breakthroughs and developments in artificial intelligence technology will bring opportunities for robots to shift from mechanical automation to intelligent development. The synergy between industrial robotics and artificial intelligence will also redefine the automation landscape. For businesses seeking to maintain a competitive advantage in the ever-evolving field of industrial robotics, it is critical to embrace change and stay ahead of the curve.

As performance improves and prices fall, the economic effects of industrial robot applications become more significant, which will help the industrial robot industry expand application scenarios and expand downstream demand. In addition, as domestic manufacturing "goes out" and global manufacturing shifts to Southeast Asia and Latin America, robots going overseas will become an important direction for future development.

The above is the detailed content of Industrial robot application scenarios: Accelerate the rush of 'trendy makers' and help the industry improve quality and efficiency. For more information, please follow other related articles on the PHP Chinese website!

Gemma Scope: Google's Microscope for Peering into AI's Thought ProcessApr 17, 2025 am 11:55 AM

Gemma Scope: Google's Microscope for Peering into AI's Thought ProcessApr 17, 2025 am 11:55 AMExploring the Inner Workings of Language Models with Gemma Scope Understanding the complexities of AI language models is a significant challenge. Google's release of Gemma Scope, a comprehensive toolkit, offers researchers a powerful way to delve in

Who Is a Business Intelligence Analyst and How To Become One?Apr 17, 2025 am 11:44 AM

Who Is a Business Intelligence Analyst and How To Become One?Apr 17, 2025 am 11:44 AMUnlocking Business Success: A Guide to Becoming a Business Intelligence Analyst Imagine transforming raw data into actionable insights that drive organizational growth. This is the power of a Business Intelligence (BI) Analyst – a crucial role in gu

How to Add a Column in SQL? - Analytics VidhyaApr 17, 2025 am 11:43 AM

How to Add a Column in SQL? - Analytics VidhyaApr 17, 2025 am 11:43 AMSQL's ALTER TABLE Statement: Dynamically Adding Columns to Your Database In data management, SQL's adaptability is crucial. Need to adjust your database structure on the fly? The ALTER TABLE statement is your solution. This guide details adding colu

Business Analyst vs. Data AnalystApr 17, 2025 am 11:38 AM

Business Analyst vs. Data AnalystApr 17, 2025 am 11:38 AMIntroduction Imagine a bustling office where two professionals collaborate on a critical project. The business analyst focuses on the company's objectives, identifying areas for improvement, and ensuring strategic alignment with market trends. Simu

What are COUNT and COUNTA in Excel? - Analytics VidhyaApr 17, 2025 am 11:34 AM

What are COUNT and COUNTA in Excel? - Analytics VidhyaApr 17, 2025 am 11:34 AMExcel data counting and analysis: detailed explanation of COUNT and COUNTA functions Accurate data counting and analysis are critical in Excel, especially when working with large data sets. Excel provides a variety of functions to achieve this, with the COUNT and COUNTA functions being key tools for counting the number of cells under different conditions. Although both functions are used to count cells, their design targets are targeted at different data types. Let's dig into the specific details of COUNT and COUNTA functions, highlight their unique features and differences, and learn how to apply them in data analysis. Overview of key points Understand COUNT and COU

Chrome is Here With AI: Experiencing Something New Everyday!!Apr 17, 2025 am 11:29 AM

Chrome is Here With AI: Experiencing Something New Everyday!!Apr 17, 2025 am 11:29 AMGoogle Chrome's AI Revolution: A Personalized and Efficient Browsing Experience Artificial Intelligence (AI) is rapidly transforming our daily lives, and Google Chrome is leading the charge in the web browsing arena. This article explores the exciti

AI's Human Side: Wellbeing And The Quadruple Bottom LineApr 17, 2025 am 11:28 AM

AI's Human Side: Wellbeing And The Quadruple Bottom LineApr 17, 2025 am 11:28 AMReimagining Impact: The Quadruple Bottom Line For too long, the conversation has been dominated by a narrow view of AI’s impact, primarily focused on the bottom line of profit. However, a more holistic approach recognizes the interconnectedness of bu

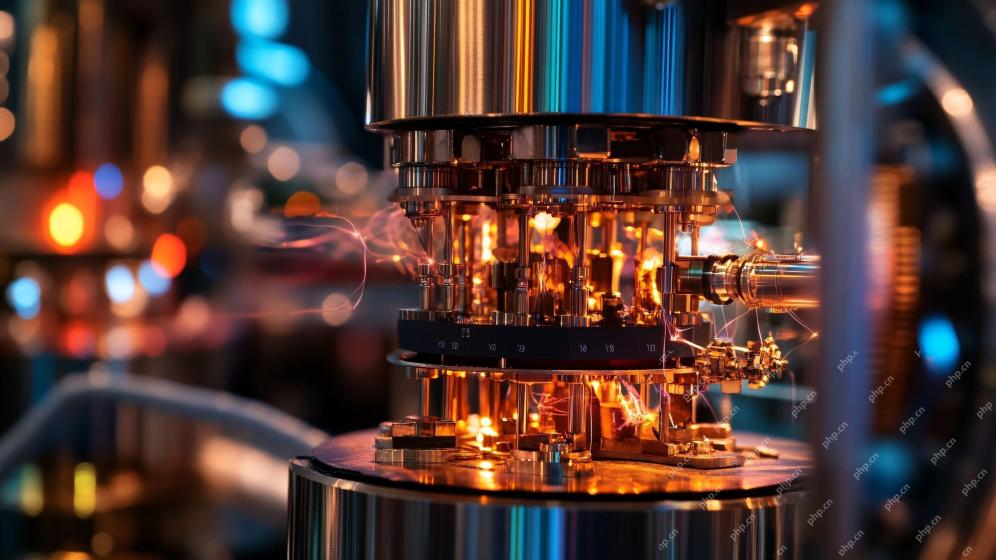

5 Game-Changing Quantum Computing Use Cases You Should Know AboutApr 17, 2025 am 11:24 AM

5 Game-Changing Quantum Computing Use Cases You Should Know AboutApr 17, 2025 am 11:24 AMThings are moving steadily towards that point. The investment pouring into quantum service providers and startups shows that industry understands its significance. And a growing number of real-world use cases are emerging to demonstrate its value out

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Zend Studio 13.0.1

Powerful PHP integrated development environment

SublimeText3 English version

Recommended: Win version, supports code prompts!

Dreamweaver CS6

Visual web development tools

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

VSCode Windows 64-bit Download

A free and powerful IDE editor launched by Microsoft