Technology peripherals

Technology peripherals AI

AI Three provinces have become 'rushing registration' areas for the industrial robot track, with the most concentrated number of companies.

Three provinces have become 'rushing registration' areas for the industrial robot track, with the most concentrated number of companies.Industrial robots such as welding and spray painting are spreading their arms in the workshops of new energy vehicles, photovoltaic manufacturing, lithium battery manufacturing and other emerging industries. In a new round of scientific and technological revolution and industrial transformation that are accelerating, as a key carrier of emerging technologies and an important starting point for the transformation of the manufacturing industry, industrial robots are profoundly affecting global technological innovation and industrial structure adjustment, and have also become a rush to increase investment among regions. new track.

According to data from Tianyancha, there are currently more than 231,000 industrial robot-related companies, of which more than 22,000 related companies were newly registered between January and October 2023. In terms of geographical distribution, the number of related enterprises in Guangdong, Jiangsu and Shandong is at the forefront. Among them, Jiangsu leads the provinces with more than 42,000 related companies, followed by Guangdong and Shandong, with more than 38,000 and 23,000 related companies respectively

It is worth noting that areas with a high concentration of industrial robot-related companies have relatively complete industrial scale, industrial chain ecological layout, urban supporting facilities, talent training and attraction, and policy mechanisms. For example, Jiangsu, Zhejiang, Guangdong and other regions all have representative companies in the industrial robot industry chain, and play a key role in assisting the transformation and upgrading of "manufacturing provinces".

The development momentum is strong and industrial clusters have been formed in the country

The world's first programmable robot was born in the United States and was first used in industrial sites in 1961. However, the robots at that time were only used for simple handling and repetitive labor. In 1973, Japan's Hitachi developed a robot with dynamic vision, and then began to be equipped with microprocessors and widely used in industry. Nowadays, modern robots have decision-making and computing capabilities, and robot development has begun to enter the intelligent era.

According to the "2023 China Robot Technology and Industry Development Report", with the rapid development of robot technology and the continuous exploration of market potential, the global robot industry is continuing to grow, and China has become an important force in promoting the development of the robot industry

In the global robot industry, China's robot industry has a very strong development momentum and has become the largest country. Through the joint efforts of all parties, China's robot industry has made continuous breakthroughs in basic core technologies, and artificial intelligence technology has also entered the world's first-class level. These achievements have laid a solid foundation for the development of the humanoid robot industry. Xu Xiaolan, Vice Minister of the Ministry of Industry and Information Technology, expressed these views at a sub-forum at the 2023 World Robot Conference

China’s huge manufacturing industry has given birth to the world’s largest industrial robot market. Since 2013, China has occupied the world’s largest industrial robot consumer market for many years. In 2022, the revenue of China's robot industry will exceed 170 billion yuan, continuing to maintain double-digit growth; industrial robot sales account for more than half of the world's sales, and the density of manufacturing robots will reach 392 units per 10,000 workers.

With the continuous development of the robot industry, China has formed unique industrial clusters in this field

The aforementioned "Report" pointed out that from the perspective of the distribution of national-level specialized and new "little giant" enterprises and listed enterprises in the field of robotics, China's high-quality robotics enterprises are mainly distributed in the Beijing-Tianjin-Hebei, Yangtze River Delta, and Pearl River Delta regions, forming a Industrial clusters represented by Beijing, Shenzhen, Shanghai, Dongguan, Hangzhou, Tianjin, Suzhou, Foshan, Guangzhou, Qingdao, etc.

According to the "Report", the robot industry in Beijing, Shenzhen and Shanghai is the strongest, while the robot industry in Dongguan, Hangzhou, Tianjin, Suzhou and Foshan is gradually developing and growing. The development potential of the robot industry in Guangzhou and Qingdao is also huge

Regional registration: Application demand drives the growth of industry scale. Regions are competing to register trademarks: application demand drives the growth of industrial scale

According to public data, in 2022, the company with the highest sales volume of industrial robots in China is Eston in Jiangsu Province, with annual sales of more than 17,000 units; while Inovance Technology in Guangdong Province has strong advantages in servo systems and control systems. In recent years, it has been catching up in the field of industrial robots, with sales second only to Eston.

In fact, the Yangtze River Delta can be said to be "far ahead" in terms of comprehensive strength in the industrial robot industry. The Yangtze River Delta is one of the most economically developed regions in China and is also an important advanced manufacturing base in China. The vigorous development of the region's economic strength has provided important technology, talent, capital, information and other industrial resource support for the robot and intelligent manufacturing equipment industry, and expanded its application areas

At present, the Yangtze River Delta region has gathered a number of well-known international and domestic robot manufacturing companies and application companies, and the regional robot production capacity accounts for more than 50% of the country's total. In addition to the four well-known international brands such as ABB, FANUC, KUKA, and Yaskawa Robotics, there are also Chinese brands such as Xinshida, Eston, and Eft, as well as independent brands such as Jika Robot, which has risen rapidly in recent years.

In the Pearl River Delta region, the application demand for industrial robots has promoted the continued expansion of industrial scale, with key industrial agglomeration areas ranking at the forefront. As one of the most active regions in the country for the development of the robot industry, the three cities of Guangzhou, Foshan and Shenzhen in Guangdong Province have obvious advantages in the robot industry. At present, the robot industry in these cities is developing towards intelligence, high-end and integration.

For example, Shenzhen City focuses on intelligent manufacturing and promotes the improvement of the intelligence level of robots; Guangzhou City uses its geographical advantages to vigorously develop high-end robot applications; Foshan City relies on its own advantages to build a high-end robot manufacturing base. By continuing to promote the demonstration application of industrial robots in high-end manufacturing and traditional pillar industries, the Pearl River Delta region has made positive progress in the field of commercial service robots

In comparison, Beijing-Tianjin-Hebei is not the region with the largest domestic robot industry, but the development quality and added value of the robot industry are relatively high. In recent years, with the strong guidance and support of national policies, relying on outstanding location advantages and good manufacturing foundation, the robot industries in Beijing, Tianjin, and Hebei in the Beijing-Tianjin-Hebei region have formed a good situation of misaligned competition and complementary advantages.

With the support of the local new generation information technology industry, the industrial robot industry in Beijing, Tianjin and Hebei has gradually moved up to the middle and high end of the value chain.

Helping the industrial transformation and upgrading of “a major manufacturing province”

By 2025, it is expected that the total scale of the robot industry in Shandong Province will reach 50 billion yuan, of which the average annual growth rate of industrial robots will exceed 25%

This is a development goal during the “14th Five-Year Plan” of Shandong Province. To achieve this goal, Shandong Province plans to create more than 40 champion companies and professional high-tech companies in the field of robotics, cultivate a number of representative application scenarios, and add more than 100 smart factories and digital workshops every year, with key areas of robotics Application coverage will be significantly improved

At the beginning of 2023, the Ministry of Industry and Information Technology released the "Implementation Plan for the "Robot" Application Action", which clearly stated that in the manufacturing field, it is necessary to promote the construction of intelligent manufacturing demonstration factories and create typical application scenarios for industrial robots. At the same time, it is also necessary to develop intelligent manufacturing systems based on industrial robots to facilitate the digital transformation and intelligent transformation of the manufacturing industry

The "China Robot Industry Development Report (2022)" shows that robots and automation have become an indispensable part of modern manufacturing in the past few years, with manufacturers integrating robotic systems in production facilities to increase production capacity and increase profits. efficiency and reduce operating costs. Industrial robots will also play an increasingly important role in the industrial transformation and upgrading of major manufacturing provinces.

A breakthrough can be found through patents

As a technology-intensive industry, the number of applications for industrial robot patent technology can reveal the technological content and level of industrial development. According to Tianyancha data, judging from the total number of patent applications for industrial robots, the number of patent applications has exceeded 10,000. Among them, utility models ranked first with more than 6,200, invention patents ranked second with more than 5,100, and appearance designs ranked first with 880 The remaining items ranked third.

As the "pearl" in the field of intelligent manufacturing, industrial robots continue to attract the attention of venture capital institutions. According to Tianyancha data, judging from the industry distribution of financing events, the number of financing events related to robots is at the forefront, with 60 cases; in addition, intelligent equipment, logistics equipment, and warehousing services are closely related downstream applications of industrial robots. The field is also a hot spot for investment and financing.

Specifically, Jiangsu, Shanghai, and Guangdong rank high in the number of financing events, with 16 (Jiangsu and Shanghai are tied) and 15 respectively; from a city perspective, Shenzhen, Nanjing, and Hefei have The number of incidents is also large, with 11, 10 and 4 incidents respectively. Judging from the geographical distribution of financing events, it can be clearly seen that the relationship between industrial robots and strong manufacturing provinces is very close, which strongly supports the upgrading of the manufacturing industry

The above is the detailed content of Three provinces have become 'rushing registration' areas for the industrial robot track, with the most concentrated number of companies.. For more information, please follow other related articles on the PHP Chinese website!

2024年工业机器人市场分析与发展趋势预测Jan 18, 2024 am 11:27 AM

2024年工业机器人市场分析与发展趋势预测Jan 18, 2024 am 11:27 AM2024年工业机器人行业应用领域市场分析及产业发展趋势预测报告发布方:中金企信国际咨询《2024-2030年工业机器人行业市场调研及战略规划投资预测报告》中金企信国际咨询相关报告推荐(2023-2024)《工业机器人项目建议书-中金企信编制》《单项冠军市场占有率-工业机器人市场占有率认证报告(2024版)》《中金企信发布-《工业机器人行业市场发展深度调查及投资战略可行性报告(2023版)》》《2023-2029年中国工业机器人专用润滑油/脂市场发展分析及未来投资潜力可行性报告》《2023-202

2023年工业机器人行业上市公司全面对比及业务布局汇总Aug 17, 2023 pm 11:41 PM

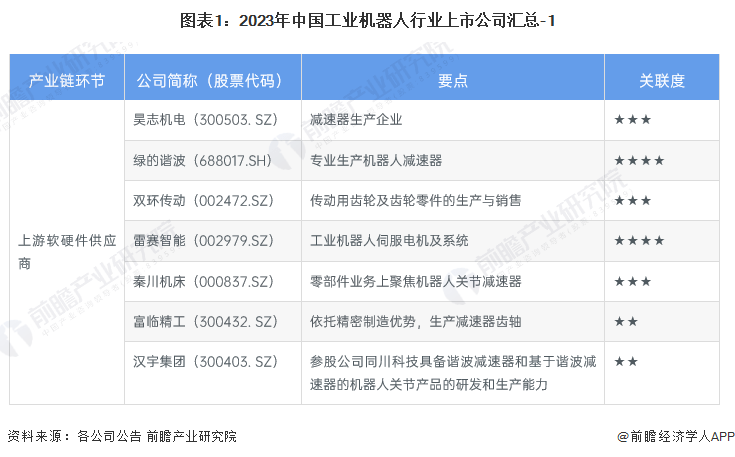

2023年工业机器人行业上市公司全面对比及业务布局汇总Aug 17, 2023 pm 11:41 PM——重写标题:2023年工业机器人行业上市公司全面比较:业务布局、业绩和业务规划等方面综合对比行业主要上市公司:机器人(300024);新时达(002527);埃斯顿(002747);汇川技术(300124);埃夫特(688165)等本文核心数据:上市公司汇总;上市公司业务布局;上市公司业绩情况;上市公司业务规划1、总结了工业机器人行业上市公司的情况工业机器人行业的核心零部件,如机器人控制系统、减速器和伺服系统,在工业机器人的成本结构中扮演着重要的角色。中游机器人制造企业通常会进行纵向整合,以便

坤博精工:生产工业机器人手臂,半导体开拓新增长曲线Nov 22, 2023 pm 05:43 PM

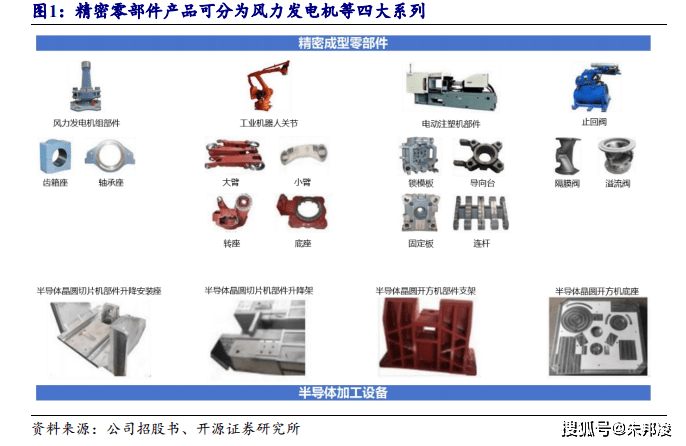

坤博精工:生产工业机器人手臂,半导体开拓新增长曲线Nov 22, 2023 pm 05:43 PM坤博精工将于23日上市。该公司有两个未被充分挖掘的亮点,一个是工业机器人手臂,另一个是半导体概念一、坤博精工生产工业机器人手臂等工业自动化设备零部件坤博精工高端装备精密成型零部件产品按照应用领域可分为风力发电机、工业自动化设备、海工装备、半导体加工设备四大系列。风力发电机零部件包括风力发电齿轮箱体座、主轴轴承座等;工业自动化设备零部件包括电动精密注塑机模板、油缸、工业机器人手臂、转座等主关节部件;海工装备零部件包括海水淡化阀门、海工涂油切割装置部件;半导体加工设备零部件包括研磨抛盘、切割机身部件

工业机器人的局限性Apr 12, 2023 pm 01:55 PM

工业机器人的局限性Apr 12, 2023 pm 01:55 PM如今,工业机器人几乎用于所有行业。它们为制造设施带来了许多好处,并为未来的智能工厂铺平了道路。然而,在选择机器人设备时,制造商应该考虑一些限制。据《财富商业洞察》报道,对自动化流程的需求正在增加,预计 2028 年工业机器人市场将达到 313 亿美元。制造商越来越意识到实施机器人的潜在商业和生产效益。然而,工业机器人并非没有缺点。以下是一些最常见的限制,以及制造商如何克服这些限制的一些建议。负担能力一般来说,工业机器人需要大量的前期投资,包括额外的安装和配置成本。制造商还需要考虑未来的维护成本和

工业机器人来焊接,优势在哪里?Apr 08, 2023 pm 02:01 PM

工业机器人来焊接,优势在哪里?Apr 08, 2023 pm 02:01 PM工业焊接机器人如何帮助用户提升焊接效率?工业焊接机器人是用于焊接作业的自动化机械设备,传统焊接中存在焊接工艺难、效率低下、招工难、焊接质量不稳定的问题,工业焊接机器人应用帮助用户解决难题,使用工业焊接机器人投入生产。这篇文章带您了解工业焊接机器人有哪些优势。1、智能焊接控制系统工业焊接机器人就具备多个传感器,电弧传感器可以进行自动寻位,电弧传感器将焊缝信息上传给控制系统,控制系统可以根据编程参数来下放刚刚好的焊接材料进行填充焊缝,减少焊件的返修率,提升焊接效率。2、多轴配合提高焊接灵活性工业焊接

PHP图像处理入门:如何使用imagecopy函数在两个图像之间复制部分区域Jul 31, 2023 pm 06:00 PM

PHP图像处理入门:如何使用imagecopy函数在两个图像之间复制部分区域Jul 31, 2023 pm 06:00 PMPHP图像处理入门:如何使用imagecopy函数在两个图像之间复制部分区域图像处理在Web开发中起着重要的作用,能够为网站增添视觉效果和吸引力。在PHP中,我们可以通过内置的GD库来处理图像。本文将介绍如何使用PHP的imagecopy函数来在两个图像之间复制部分区域。GD库是一个用于处理图像的开源工具包,可以用于创建、操纵和保存图像。它提供了一系列的函数

配置Linux系统以支持工业机器人和自动化生产开发Jul 04, 2023 pm 12:01 PM

配置Linux系统以支持工业机器人和自动化生产开发Jul 04, 2023 pm 12:01 PM配置Linux系统以支持工业机器人和自动化生产开发随着工业机器人和自动化生产的快速发展,越来越多的企业开始使用Linux系统来支持它们的生产开发。Linux系统具有良好的稳定性、灵活性和可定制性,这使得它成为一个理想的选择。本文将介绍如何配置Linux系统以支持工业机器人和自动化生产开发,并提供一些代码示例。安装Linux系统首先,您需要选择一个适合的Lin

如何在Go中使用SectionReader模块实现文件指定区域的内容搜索?Jul 21, 2023 pm 04:57 PM

如何在Go中使用SectionReader模块实现文件指定区域的内容搜索?Jul 21, 2023 pm 04:57 PM如何在Go中使用SectionReader模块实现文件指定区域的内容搜索?概述在Go语言中,SectionReader模块提供了一种方便的方式来读取具有特定区域的文件内容。通过SectionReader,我们可以定位文件的指定区域,并且只读取该区域的内容,这在处理大文件或者需要按区域读取文件内容的场景中非常有用。本文将介绍如何使用SectionReader模

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

Notepad++7.3.1

Easy-to-use and free code editor

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

Atom editor mac version download

The most popular open source editor

SublimeText3 Linux new version

SublimeText3 Linux latest version