Technology peripherals

Technology peripherals AI

AI Hairou's innovative hook-type ACR, ultra-fast latent lifting robot K50 and other products were unveiled at CeMAT Asia 2023

Hairou's innovative hook-type ACR, ultra-fast latent lifting robot K50 and other products were unveiled at CeMAT Asia 2023CeMAT Asia2023 Asian Logistics Exhibition kicked off on October 24 at the Shanghai New International Expo Center. The hook-type ACR (Automated Case-handling Mobile Robot) and the extremely fast latent lifting robot K50 in HaiPick System 3, the latest innovative system product of Hairou, were unveiled at offline exhibitions for the first time. After the customer applied the hook-type ACR, the warehouse can store more than 50 standard material boxes per square meter, and the storage density has been greatly improved; it can support 20mm left and right box spacing between material boxes, and 0 back-to-back spacing. One shelf supports up to five materials. The depth of the box is deployed; coupled with the fact that there is no need to recognize QR codes to pick up goods, the forks can be lifted and lowered faster, and the overall picking and placing efficiency can be increased by up to 30%.

[Haier CeMAT booth is located in Hall N1 B2]

HaiPick System 3 robot product makes stunning debut

HaiPick System 3 consists of a hook-type ACR, an extremely fast latent lifting AMR, a HaiPort workstation, shelves, bins, and HaiQ smart warehousing management platform. It has four major features: high flexibility, efficient scheduling, ultimate storage, and friendly interaction. advantages to help customers improve the competitiveness of smart logistics.

ACR and the extremely fast latent jacking AMR can work together to achieve complementary advantages: ACR focuses on the material box storage area, arranges reasonable storage locations according to the heat distribution of the warehouse, and puts the hottest goods downward; the extremely fast latent lift The lifting robot K50 has a speed of up to 4m/s. It focuses on moving boxes from the bottom of the shelf to the workstation and flexibly connects the conveyor line. The hook-type pick-and-place technology is applied to Hairou's multi-layer bin robot HaiPick A42 and telescopic lifting bin robot HaiPick A42T. The HaiPick A42 robot has an operating height of 0-6 meters, and the HaiPick A42T operating height is 0 -10 m. What was on display at the CeMAT exhibition was the HaiPick A42T-E2, which can be picked up from 10 meters away. The intuitive and shocking effect attracted many customers to stop and watch.

HaiPick System 3 supports mixed field scheduling of up to 1,000 robots to meet ultra-high business traffic; in terms of storage density, overpass shelves can be deployed with aisles of more than 6 meters, approaching "solid" storage, which further improves space utilization. Picker operation is a part of logistics efficiency. Friendly and safe interaction allows pickers to complete their work easily and efficiently, which is also one of the important considerations in product design. In front of the workstation, the K50 can flexibly configure the lifting height according to the worker's height, making picking easier. K50 is equipped with lidar, which can automatically follow the car in 2 seconds, which is comparable to the box supply speed of the conveyor line. The maximum efficiency can reach 350 boxes/hour/person.

Integrated production and warehouse solution: A3S realizes lineside handling and storage in one machine

Intelligent lifting robot A3S is an intelligent lifting robot developed for SMT scenarios. This product integrates advanced software and hardware technology and has functions such as intelligent handling, autonomous navigation, active obstacle avoidance, and automatic charging. It adopts a composite pick-and-place method of chain conveying and lifting to support the anti-static of the entire machine. It is equipped with a central clamping and correction device, realizing a point-to-point transportation solution of "cache shelf to machine", which is highly consistent with the process characteristics of SMT scenarios.

[Hairou innovative intelligent lifting robot A3S]

【Hairou Lifting Robot A3】

The production and warehouse integrated solution is an integrated solution that includes picking, handling, automatic loading and unloading and other scenarios. It consists of A42 series box storage robots, A3 series lifting robots, latent lifting robots (AMR), The HaiQ intelligent warehouse management platform and other software and hardware products help electronic manufacturing customers complete the picking business processes such as raw material warehousing, semi-finished product warehousing, finished product warehousing, tooling and fixture warehousing, etc., while also realizing the production line distribution of picked materials and the materials between production lines. Circulation and automatic loading and unloading.

This solution can realize full-scenario integrated production and warehouse planning for customers, expand to the next 3-5 years, and can be flexibly deployed in phases and flexibly adapted to business changes. Materials are automatically connected to production line stations to realize machine replacement operations. SLAM-ACR can be transported at the production line station and feed materials in a finer granularity mode. Through the combination of robots and HaiQ smart warehousing management platform, production information can be traced throughout the entire process, preventing waste and wrong materials, and helping customers achieve lean production through informatization, intelligence, and data visualization.

Empower customers with robotics technology to achieve high-quality development

The Fifth International Mobile Robot and Industrial Global Logistics Integrator Conference hosted by the New Strategic Mobile Robot Alliance was also successfully held on the same day. Liu Jingtao, Vice President of Innovation at Hairou, attended and delivered a speech, expressing his hope for the vigorous development of China's industrial mobile robot industry and calling on industry partners to work together to make robotics technology a Chinese business card that shines in the world.

[Hairou Innovation Vice President Liu Jingtao delivered a speech]

[Lu Xintong, Head of Programs of Hairou Domestic Business Center, delivered a speech]

Lu Xintong, head of solutions at Hairou Innovation Domestic Business Center, delivered a keynote speech on "How to leverage the core advantages of box-type warehousing robots and build digital intelligent warehousing logistics", introducing in detail the core advantages of Hairou's innovative system product solutions. He also said that Hairou will be deeply rooted in the business scenarios of corporate customers, deeply integrated with corporate business processes, and will use the world's leading robotics technology to empower customers to the greatest extent and achieve high-quality development.

The above is the detailed content of Hairou's innovative hook-type ACR, ultra-fast latent lifting robot K50 and other products were unveiled at CeMAT Asia 2023. For more information, please follow other related articles on the PHP Chinese website!

The AI Skills Gap Is Slowing Down Supply ChainsApr 26, 2025 am 11:13 AM

The AI Skills Gap Is Slowing Down Supply ChainsApr 26, 2025 am 11:13 AMThe term "AI-ready workforce" is frequently used, but what does it truly mean in the supply chain industry? According to Abe Eshkenazi, CEO of the Association for Supply Chain Management (ASCM), it signifies professionals capable of critic

How One Company Is Quietly Working To Transform AI ForeverApr 26, 2025 am 11:12 AM

How One Company Is Quietly Working To Transform AI ForeverApr 26, 2025 am 11:12 AMThe decentralized AI revolution is quietly gaining momentum. This Friday in Austin, Texas, the Bittensor Endgame Summit marks a pivotal moment, transitioning decentralized AI (DeAI) from theory to practical application. Unlike the glitzy commercial

Nvidia Releases NeMo Microservices To Streamline AI Agent DevelopmentApr 26, 2025 am 11:11 AM

Nvidia Releases NeMo Microservices To Streamline AI Agent DevelopmentApr 26, 2025 am 11:11 AMEnterprise AI faces data integration challenges The application of enterprise AI faces a major challenge: building systems that can maintain accuracy and practicality by continuously learning business data. NeMo microservices solve this problem by creating what Nvidia describes as "data flywheel", allowing AI systems to remain relevant through continuous exposure to enterprise information and user interaction. This newly launched toolkit contains five key microservices: NeMo Customizer handles fine-tuning of large language models with higher training throughput. NeMo Evaluator provides simplified evaluation of AI models for custom benchmarks. NeMo Guardrails implements security controls to maintain compliance and appropriateness

AI Paints A New Picture For The Future Of Art And DesignApr 26, 2025 am 11:10 AM

AI Paints A New Picture For The Future Of Art And DesignApr 26, 2025 am 11:10 AMAI: The Future of Art and Design Artificial intelligence (AI) is changing the field of art and design in unprecedented ways, and its impact is no longer limited to amateurs, but more profoundly affecting professionals. Artwork and design schemes generated by AI are rapidly replacing traditional material images and designers in many transactional design activities such as advertising, social media image generation and web design. However, professional artists and designers also find the practical value of AI. They use AI as an auxiliary tool to explore new aesthetic possibilities, blend different styles, and create novel visual effects. AI helps artists and designers automate repetitive tasks, propose different design elements and provide creative input. AI supports style transfer, which is to apply a style of image

How Zoom Is Revolutionizing Work With Agentic AI: From Meetings To MilestonesApr 26, 2025 am 11:09 AM

How Zoom Is Revolutionizing Work With Agentic AI: From Meetings To MilestonesApr 26, 2025 am 11:09 AMZoom, initially known for its video conferencing platform, is leading a workplace revolution with its innovative use of agentic AI. A recent conversation with Zoom's CTO, XD Huang, revealed the company's ambitious vision. Defining Agentic AI Huang d

The Existential Threat To UniversitiesApr 26, 2025 am 11:08 AM

The Existential Threat To UniversitiesApr 26, 2025 am 11:08 AMWill AI revolutionize education? This question is prompting serious reflection among educators and stakeholders. The integration of AI into education presents both opportunities and challenges. As Matthew Lynch of The Tech Edvocate notes, universit

The Prototype: American Scientists Are Looking For Jobs AbroadApr 26, 2025 am 11:07 AM

The Prototype: American Scientists Are Looking For Jobs AbroadApr 26, 2025 am 11:07 AMThe development of scientific research and technology in the United States may face challenges, perhaps due to budget cuts. According to Nature, the number of American scientists applying for overseas jobs increased by 32% from January to March 2025 compared with the same period in 2024. A previous poll showed that 75% of the researchers surveyed were considering searching for jobs in Europe and Canada. Hundreds of NIH and NSF grants have been terminated in the past few months, with NIH’s new grants down by about $2.3 billion this year, a drop of nearly one-third. The leaked budget proposal shows that the Trump administration is considering sharply cutting budgets for scientific institutions, with a possible reduction of up to 50%. The turmoil in the field of basic research has also affected one of the major advantages of the United States: attracting overseas talents. 35

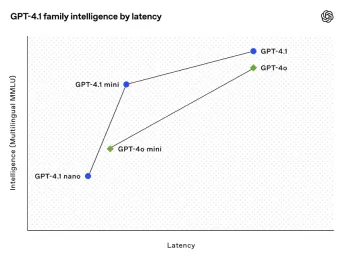

All About Open AI's Latest GPT 4.1 Family - Analytics VidhyaApr 26, 2025 am 10:19 AM

All About Open AI's Latest GPT 4.1 Family - Analytics VidhyaApr 26, 2025 am 10:19 AMOpenAI unveils the powerful GPT-4.1 series: a family of three advanced language models designed for real-world applications. This significant leap forward offers faster response times, enhanced comprehension, and drastically reduced costs compared t

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

SublimeText3 Linux new version

SublimeText3 Linux latest version

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.

VSCode Windows 64-bit Download

A free and powerful IDE editor launched by Microsoft

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment

SublimeText3 Chinese version

Chinese version, very easy to use