China News Service, Urumqi, October 22 (Wang Zechao, Wei Chao) On the 21st, in the 220 kV Fannan substation in Gaochang District, Turpan, Xinjiang, an intelligent inspection robot was steadily crossing switches one by one along the track. Cabinets and protective screens are used to collect temperature, meter and other data "with ease". At the same time, on the screen of the remote intelligent inspection system of the central control station of the State Grid Turpan Power Supply Company, the high-definition picture taken by the inspection robot is displayed in real time. The operation and maintenance personnel only need to record the picture information through the robot to analyze the contents of the substation. The operation of the equipment.

An intelligent inspection robot independently conducts inspections at the 220 kV Tuokxun Industrial Park substation. Photo by Wei Chao

In order to improve the automation and intelligence level of substation operation and maintenance, State Grid Turpan Power Supply Company introduced 11 intelligent inspection robots to monitor the operating status of live equipment in the substation in real time and efficiently, creating a complete intelligent inspection system to complete the " The transition from "human patrols as the main part and machine patrols as the supplement" to "machine patrols as the main part and human patrols as the supplement".

According to reports, compared with traditional manual inspections, intelligent inspection robots can effectively explore blind spots and provide more comprehensive data for equipment condition assessment. After the intelligent inspection robot departs from the charging compartment, the infrared thermal imager it carries will display the temperature of each part of the equipment in real time. The visible light high-definition camera can accurately identify the readings of various instruments in the substation, and it only takes about fifteen minutes to complete a single line. Interval equipment inspections effectively save manpower and time.

"The intelligent inspection robot has multiple functions such as fixed-point path inspection, remote control inspection, high-definition visible light and infrared real-time video monitoring, transformer and reactor noise monitoring, etc. It can carry out multi-dimensional and blind-angle observation of the equipment in the substation. Realize early detection and early treatment of equipment defects and hidden dangers." Dilimulati Mijiti, the person in charge of operation and maintenance technology of the substation operation and maintenance center, said.

In the next step, State Grid Xinjiang Electric Power will continue to expand the breadth and depth of inspection robot applications, further enhance the digitalization, intelligence, automation and informatization level of substation operation and maintenance, achieve refined operation and maintenance management, and contribute to the safety and stability of the power grid. Operation escort. (over)

The above is the detailed content of Xinjiang intelligent inspection robot 'on duty' to ensure power supply. For more information, please follow other related articles on the PHP Chinese website!

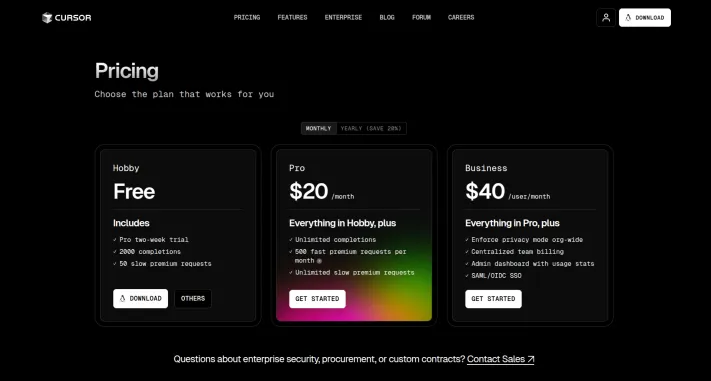

I Tried Vibe Coding with Cursor AI and It's Amazing!Mar 20, 2025 pm 03:34 PM

I Tried Vibe Coding with Cursor AI and It's Amazing!Mar 20, 2025 pm 03:34 PMVibe coding is reshaping the world of software development by letting us create applications using natural language instead of endless lines of code. Inspired by visionaries like Andrej Karpathy, this innovative approach lets dev

How to Use DALL-E 3: Tips, Examples, and FeaturesMar 09, 2025 pm 01:00 PM

How to Use DALL-E 3: Tips, Examples, and FeaturesMar 09, 2025 pm 01:00 PMDALL-E 3: A Generative AI Image Creation Tool Generative AI is revolutionizing content creation, and DALL-E 3, OpenAI's latest image generation model, is at the forefront. Released in October 2023, it builds upon its predecessors, DALL-E and DALL-E 2

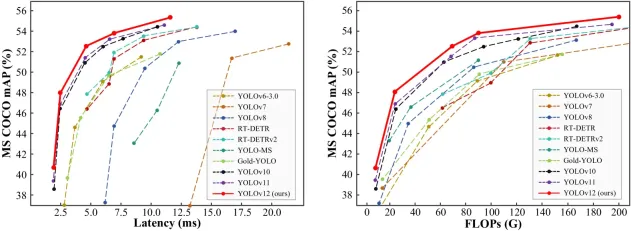

How to Use YOLO v12 for Object Detection?Mar 22, 2025 am 11:07 AM

How to Use YOLO v12 for Object Detection?Mar 22, 2025 am 11:07 AMYOLO (You Only Look Once) has been a leading real-time object detection framework, with each iteration improving upon the previous versions. The latest version YOLO v12 introduces advancements that significantly enhance accuracy

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!Mar 22, 2025 am 10:58 AM

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!Mar 22, 2025 am 10:58 AMFebruary 2025 has been yet another game-changing month for generative AI, bringing us some of the most anticipated model upgrades and groundbreaking new features. From xAI’s Grok 3 and Anthropic’s Claude 3.7 Sonnet, to OpenAI’s G

Elon Musk & Sam Altman Clash over $500 Billion Stargate ProjectMar 08, 2025 am 11:15 AM

Elon Musk & Sam Altman Clash over $500 Billion Stargate ProjectMar 08, 2025 am 11:15 AMThe $500 billion Stargate AI project, backed by tech giants like OpenAI, SoftBank, Oracle, and Nvidia, and supported by the U.S. government, aims to solidify American AI leadership. This ambitious undertaking promises a future shaped by AI advanceme

Sora vs Veo 2: Which One Creates More Realistic Videos?Mar 10, 2025 pm 12:22 PM

Sora vs Veo 2: Which One Creates More Realistic Videos?Mar 10, 2025 pm 12:22 PMGoogle's Veo 2 and OpenAI's Sora: Which AI video generator reigns supreme? Both platforms generate impressive AI videos, but their strengths lie in different areas. This comparison, using various prompts, reveals which tool best suits your needs. T

Google's GenCast: Weather Forecasting With GenCast Mini DemoMar 16, 2025 pm 01:46 PM

Google's GenCast: Weather Forecasting With GenCast Mini DemoMar 16, 2025 pm 01:46 PMGoogle DeepMind's GenCast: A Revolutionary AI for Weather Forecasting Weather forecasting has undergone a dramatic transformation, moving from rudimentary observations to sophisticated AI-powered predictions. Google DeepMind's GenCast, a groundbreak

Which AI is better than ChatGPT?Mar 18, 2025 pm 06:05 PM

Which AI is better than ChatGPT?Mar 18, 2025 pm 06:05 PMThe article discusses AI models surpassing ChatGPT, like LaMDA, LLaMA, and Grok, highlighting their advantages in accuracy, understanding, and industry impact.(159 characters)

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

WebStorm Mac version

Useful JavaScript development tools

Atom editor mac version download

The most popular open source editor

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment