How can manufacturers use digital twins to improve productivity?

Manufacturers are investing in a variety of advanced technologies to gain a competitive advantage, reduce costs, and provide customers with a more tailored experience. One of the key technologies being used in manufacturing is virtual simulation, or digital twins, whose use has been on the rise in recent years and is starting to be embraced by manufacturers of all sizes.

What is a digital twin

Digital twin is a concept covering multiple fields. It is based on digital technology and data analysis and attempts to create a digital copy or model of the real world. , in order to better understand, simulate and optimize physical entities or processes. Digital twins usually include the following aspects:

Modeling and simulation of physical entities:Digital twins involve the creation of digital models of physical entities (such as machines, equipment, buildings, etc.). Models can simulate actual physical processes and behaviors. This helps improve design, predictive maintenance and performance optimization.

Real-time data capture and monitoring: Digital twins utilize sensors and data acquisition technology to feed real-time data into the digital model so that the accuracy of the digital twin can be continuously updated and improved. This helps monitor and manage the status of physical entities.

Decision support: A key goal of digital twins is to provide decision support. Through digital twins, the impact of different decisions on physical entities can be simulated, helping decision makers better understand potential risks and opportunities.

Optimization and Prediction: Digital twins allow for experimentation and optimization to improve the performance of physical entities. It can also be used to predict future trends and issues and help make appropriate decisions.

Digital twins have a wide range of applications, including manufacturing, urban planning, healthcare, energy management, and environmental monitoring. Through digital twins, organizations and individuals can better understand and manage complex systems to improve efficiency, reduce costs, and even provide better products and services. This concept has received widespread attention and applications in fields such as Industry 4.0 and smart cities

How manufacturers adopt digital twins to improve productivity

Digital twins are an application Technology for the virtual representation of objects, especially machines. Manufacturers can use digital twins to design, run and test operations in a controlled virtual environment before bringing them to the actual shop floor. Digital twins can also help manufacturers gain a deeper understanding of mid- to long-term operations, using accelerated testing to assess machine durability and the frequency of parts repairs

Virtual commissioning is a term used in manufacturing and is also a digital twin One of the fastest growing sub-sectors in the market. The past few years have seen a significant increase in the number of manufacturers entering the realm of advanced simulation and virtual debugging. Manufacturers can use virtual debugging to preview debugging results before conducting physical machine testing. The process is similar to what many industries go through with their clients, where they present the design online and allow the client to make suggestions and changes before the physical unit is produced. In this way, not only are costs reduced, customers are also able to participate in more of the development process

Although digital twins have more advantages in manufacturing, people are conservative about adopting leading technologies. Many manufacturers rarely make large-scale investments because equipment and technology upgrades are costly. At the same time, manufacturers are facing a tough economic outlook, with raw material costs rising rapidly

Manufacturers are struggling to acquire the talent they need to undertake digital transformation, with some having to use off-the-shelf services instead Develop your own services. While this may be sensible in the short term, in the long term manufacturers need to differentiate themselves from the competition, and one of the key ways to achieve this is to have purpose-built software

The above is the detailed content of How can manufacturers use digital twins to improve productivity?. For more information, please follow other related articles on the PHP Chinese website!

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AM

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AMRunning large language models at home with ease: LM Studio User Guide In recent years, advances in software and hardware have made it possible to run large language models (LLMs) on personal computers. LM Studio is an excellent tool to make this process easy and convenient. This article will dive into how to run LLM locally using LM Studio, covering key steps, potential challenges, and the benefits of having LLM locally. Whether you are a tech enthusiast or are curious about the latest AI technologies, this guide will provide valuable insights and practical tips. Let's get started! Overview Understand the basic requirements for running LLM locally. Set up LM Studi on your computer

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AM

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AMGuy Peri is McCormick’s Chief Information and Digital Officer. Though only seven months into his role, Peri is rapidly advancing a comprehensive transformation of the company’s digital capabilities. His career-long focus on data and analytics informs

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AM

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AMIntroduction Artificial intelligence (AI) is evolving to understand not just words, but also emotions, responding with a human touch. This sophisticated interaction is crucial in the rapidly advancing field of AI and natural language processing. Th

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AM

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AMIntroduction In today's data-centric world, leveraging advanced AI technologies is crucial for businesses seeking a competitive edge and enhanced efficiency. A range of powerful tools empowers data scientists, analysts, and developers to build, depl

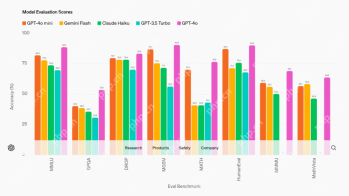

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AM

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AMThis week's AI landscape exploded with groundbreaking releases from industry giants like OpenAI, Mistral AI, NVIDIA, DeepSeek, and Hugging Face. These new models promise increased power, affordability, and accessibility, fueled by advancements in tr

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AM

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AMBut the company’s Android app, which offers not only search capabilities but also acts as an AI assistant, is riddled with a host of security issues that could expose its users to data theft, account takeovers and impersonation attacks from malicious

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AM

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AMYou can look at what’s happening in conferences and at trade shows. You can ask engineers what they’re doing, or consult with a CEO. Everywhere you look, things are changing at breakneck speed. Engineers, and Non-Engineers What’s the difference be

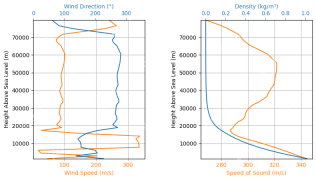

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AM

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AMSimulate Rocket Launches with RocketPy: A Comprehensive Guide This article guides you through simulating high-power rocket launches using RocketPy, a powerful Python library. We'll cover everything from defining rocket components to analyzing simula

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

SublimeText3 Linux new version

SublimeText3 Linux latest version

Dreamweaver Mac version

Visual web development tools

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.

SublimeText3 Mac version

God-level code editing software (SublimeText3)