Technology peripherals

Technology peripherals AI

AI The new Jiexiang Lingli warehouse pallet robot: subverting the unmanned forklift track!

The new Jiexiang Lingli warehouse pallet robot: subverting the unmanned forklift track!The new Jiexiang Lingli warehouse pallet robot: subverting the unmanned forklift track!

By the third quarter, needless to say, the unmanned forklift track has become extremely popular

Data from the Advanced Robotics Industry Research Institute (GGII) shows that in 2022, the sales volume of domestic unmanned forklifts exceeded 10,000 units for the first time, reaching 11,315 units, with a growth rate of 53.42%. The average annual compound growth rate in the past five years has been nearly 10,000 units. 72%. Its market size has also expanded simultaneously, exceeding 2 billion in 2022, reaching 2.263 billion, a year-on-year increase of 38.85%.

According to the survey of Gaogong Mobile Robot, after entering 2023, unmanned forklift companies have shown strong growth momentum. According to industry estimates, the overall growth rate of the unmanned forklift market in the first two quarters was between 60% and 80%. Some leading companies revealed that revenue and order volume in the first half of the year doubled year-on-year, and this year's performance goals have been completed ahead of schedule. In view of the optimistic feedback from various companies, despite the sluggish performance of the entire mobile robot industry, GGII predicts that the unmanned forklift market will still expand rapidly this year, with sales exceeding 18,000 units and a growth rate of nearly 60%

Carefully sort out the main players of unmanned forklifts at present, and they can basically be divided into three types: traditional forklift companies, AGV/AMR companies and unmanned forklift companies. The competitive advantages of various types of companies are different: traditional forklift companies rely on their deep accumulation of vehicle body technology and mature channel network advantages; AGV/AMR companies focus on unmanned and automated technology and implementation experience; unmanned forklift companies He has been focusing on unmanned forklifts for a long time and has a deep understanding of product pain points, iteration and product delivery.

However, in the final analysis, the underlying logic of these three types of enterprises is similar: first carry out unmanned and automated transformation of manual forklifts, and then adapt them to different manufacturing and logistics industry scenarios after having the products. In order to replace the current large number of manual forklifts. In short, after you have a "hammer" (unmanned forklift), you can then look for "nails" (scenarios).

Jiexiang Lingyue has always adhered to the concept of "subversive innovation" and opened up a new path in this track: first aiming at a specific landing scenario, starting from the actual needs, to develop products that can hit the user's pain points. The product.

Continuing the JE-1200U and JE-1200E series they previously launched, the latest JE-1200FK series of vertical warehouse pallet robots launched by Jiexiang Lingyue is their brand new answer to the industry.

We hope to change the status quo of this track

Jiexiang Lingyue’s gene is subversion and innovation

Since its establishment, Jiexiang Lingyue has positioned itself as a "pallet handling expert", emphasizing that its product is a "pallet robot" and making no secret of its goal to "create the forklift 3.0 era." The previously launched JE-1200U and JE-1200E series products are completely different from traditional unmanned forklifts. The JE-1200FK launched now is a continuation of previous innovative breakthroughs.

Jiexiang Lingyue Product Matrix

On the one hand, Jiexiang Lingyue hopes to distinguish itself from the current unmanned forklift companies and looks forward to innovating unmanned forklifts from the bottom up. At present, the product idea of many unmanned forklift companies is to modify manual forklifts with software systems such as navigation control. Although this is low-cost, at the beginning of the design of manual forklifts, both the overall body and the movement method were based on manual control, and automatic equipment was directly installed. There was no way to unleash the full potential of automation technology, and it fell into the traditional forklift design. In the shackles.

The lifting height of the JE-1200FK series can reach 2.5 meters, 4.6 meters, and 6.5 meters respectively

The product positioning of "pallet robot" allows Jiexiangling to transcend the constraints of traditional forklift forms and technologies and pay more attention to the "primary issue" of industrial logistics: What are the objects we need to transport? What are our needs during the moving process? What method of transportation do we choose? What kind of handling equipment do we need?

By mentally subverting the industry's understanding of unmanned forklifts, Jiexiang Lingyue hopes to redefine the form of future forklifts, and even the form of future automated handling equipment.

On the other hand, the demand for customization has always caused headaches for unmanned forklift companies. The revenue brought by the project is of course very attractive, but debugging, implementing and optimizing products according to the needs and pain points of different manufacturers, environments and scenarios often costs companies a huge amount of time and money, and the products created are Difficult to replicate at scale.

Jiexiangling only wanted to make standard products from the beginning, and their goal was to provide standard solutions in standard scenarios. Therefore, they focus on pallet and warehouse scenarios

The reason why these two are the most common standardized carriers is very simple: there are national standards for pallets. No matter what goods the company transports, using Tiantuo or Chuanto pallets, the handling robot can easily adapt; and automated warehouses It has become a necessity in the industrial and logistics industries. Beam-type shelves and through-type shelves are common in vertical warehouse scenes, and they also have national standards. Using these two relatively fixed and relatively standard carriers as the benchmark for the design of handling robots, it is more likely to develop standard products that can cross industries and scenarios

It is the combination of these two ideas that Jiexiang Lingyue launched the JE-1200FK series of pallet robots focusing on vertical warehouse scenarios. In the warehouse scene that has always been dominated by stackers and four-way shuttles, Jiexiang Lingyue is planning to create a new form of unmanned forklift, which may open up a new, scalable track.

How to build a futuristic unmanned forklift?

The word "subversion" certainly makes people excited, but to truly realize it, it still requires down-to-earth hard work and dedication.

How to build an unmanned forklift of the future? Jiexiang Lingyue refused to find a "nail" for the "hammer", but chose to start from the scenario and demand, and summarized the three major problems of current customers Pain points: safety, efficiency, flexibility.

First of all, security is undoubtedly the primary demand of downstream customers. The weight of an unmanned forklift is very large. When fully loaded, most products can weigh more than a car. In addition, due to the demand for logistics rhythm, the speed of unmanned forklifts is not slow. If it hits goods or people, it will cause damage to the goods at least, and injuries or even death to people at worst. This raises questions about the safety performance of unmanned forklifts. huge challenge.

In response to this demand, the JE-1200FK series has reached the highest level in terms of both passive safety performance and active safety performance

From the perspective of passive safety design, the JE-1200FK series is liberated from the shackles of traditional forklifts and innovates the body design.

The center of gravity of a traditional forklift will change greatly depending on the weight of the goods being forked, which may lead to overturning due to an unstable center of gravity. The isosceles triangle center of gravity support structure design adopted by Jiexiang Lingyue's new products allows the robot's center of gravity to always change in an approximate isosceles triangle structure during the process of lifting goods. The overall center of gravity is consistent whether it is empty or fully loaded. sex. Compared with traditional forklifts, it can achieve optimal cargo stability and ensure safe storage access operations.

In addition, due to the new car body structure design, all cargo is located within the car body frame. Therefore, regardless of whether the robot is in a lifting state or a moving state, the position of the goods is more stable. The robot chassis is also equipped with a 360° full coverage anti-collision edge to provide the car body with stable and reliable bottom contact collision safety capabilities.

In terms of active safety devices, the JE-1200FK series achieves all-round safety perception capabilities by adopting "multi-lidar multi-directional cargo detection" technology. It can sense the front and rear, low and suspended areas of the car body, achieving a sensing range without blind spots

According to Jiexiang Lingyue, the robot chassis is equipped with 1 laser radar in the front and rear center; 6 sensors are placed on both sides of the vehicle body, covering the side sensing area; a TOF sensor is also installed on the front of the vehicle to realize the mast physical collision perception and suspension perception.

The JE-1200FK series’ all-round safety sensing capabilities also include monitoring the status of the fork tines. It is reported that the robot can also realize fork tip collision sensing, fork tip non-contact sensing, cargo arrival sensing, and after-lifting heavy objects. , the mast will be pitched and deformed due to stress. In order to prevent the cargo from tipping, the fork tines will be self-compensated based on the deformation.

It can be seen that the security protection performance of the JE-1200FK series is "full" and accurately hits the core pain points of customers.

In addition to safety, cost reduction and efficiency improvement are always the fundamental reasons for downstream users to adopt automation equipment. The JE-1200FK series is also excellent in efficient use of space.

First of all, the load capacity of the JE-1200FK series is constant and will not change due to height. According to industry insiders, traditional forklifts have a load curve chart. When the lifting height of the forklift is higher, the rated lifting load will be significantly reduced. For example, the rated lifting load of a forklift is 1.2 tons. When it is lifted to 6 meters, The weight it can carry is only about 0.6 tons, which means that in the raw material warehouses and finished product warehouses with "small categories, large storage capacity, and high turnover" in the manufacturing industry, many heavy goods cannot be placed in high storage locations, resulting in a waste of space.

The load-bearing structure design of the JE-1200FK series ensures that the equivalent center of gravity does not shift during cargo lifting. Even if it reaches the highest lifting position, the robot's load capacity can still be maintained at 1200kg, thus ensuring the space utilization of medium and high storage spaces. Rate

Secondly, its body design requires less space for operation. Since the JE-1200FK series can rotate in situ with the center of the car body shape as the origin, it occupies less space when turning, and the minimum turning radius is only 0.93 meters, so the product can meet the needs of ultra-narrow shelf aisles.

JE-1200FK series forklifts require smaller space than general counterbalanced forklifts or reach forklifts, and can improve the efficiency of multi-vehicle traffic. In the same area, it can place more shelves and increase the storage capacity by 30%

In addition, the JE-1200FK series also meets the high-precision requirements of downstream users for automation equipment. According to Jiexiang Lingyue, the product can be implemented in real life, with positioning accuracy and lifting accuracy reaching ±10mm and ±5mm respectively. With high precision and high stability of lifting capacity, the JE-1200FK series high-level cargo can be transported in a single The picking and placing efficiency is 20% higher than that of a manned forklift.

Under the trend of intelligent manufacturing, flexibility has become one of the core competitiveness of enterprises. When Jiexiang Lingyue created the JE-1200FK series of products, of course it also focused on flexibility as its core focus

Before the introduction of the JE-1200FK series, there was no need for civil engineering modifications and special racking, and it could work directly in standard back-to-back beam racking and through-racking environments. Moreover, the deployment process can achieve non-stop production and work, and also supports phased implementation by region and output, and supports single-vehicle deployment and sub-regional deployment, which minimizes the impact of warehouse automation upgrades on the original production rhythm and greatly reduces the introduction of Cost threshold of JE-1200FK

How far is the forklift 3.0 era?

Data shows that as of the end of 2020, the number of manual forklifts in China has exceeded 4 million, and the total domestic sales in 2021 and 2022 will exceed 1.48 million. As an automated upgraded version of manual forklifts, unmanned forklifts have a huge potential market.

Is "manual forklift automation" the future of unmanned forklifts? It can be seen that many players on the unmanned forklift track are running along this logic.

However, the answer given by Jiexianglingyue is no. 3.0 forklifts are not just about adding navigation equipment to the forklift, but rethinking and designing the vehicle body structure and underlying technology based on the needs of today's smart factories and warehouses, and integrating them with the entire logistics solution

What they want to do is not just a new product, they want to change people's fundamental understanding of forklifts. But to change the minds of players and downstream users, companies not only need courage, but also bold imagination and solid product capabilities.

In the final analysis, what customers need is a cost-effective logistics solution that can solve actual handling needs. The form of manual forklifts was fixed based on the needs of the previous generation of industrial logistics. However, with the rapid changes in the industry, logistics scenarios and technology, the new generation of forklifts will inevitably change according to the needs of the times, but the direction of product changes has not yet been determined

JE-1200FK series is another attempt by Jiexiang Lingyue to end the 2.0 era of forklifts

The above is the detailed content of The new Jiexiang Lingli warehouse pallet robot: subverting the unmanned forklift track!. For more information, please follow other related articles on the PHP Chinese website!

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AM

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AMRunning large language models at home with ease: LM Studio User Guide In recent years, advances in software and hardware have made it possible to run large language models (LLMs) on personal computers. LM Studio is an excellent tool to make this process easy and convenient. This article will dive into how to run LLM locally using LM Studio, covering key steps, potential challenges, and the benefits of having LLM locally. Whether you are a tech enthusiast or are curious about the latest AI technologies, this guide will provide valuable insights and practical tips. Let's get started! Overview Understand the basic requirements for running LLM locally. Set up LM Studi on your computer

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AM

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AMGuy Peri is McCormick’s Chief Information and Digital Officer. Though only seven months into his role, Peri is rapidly advancing a comprehensive transformation of the company’s digital capabilities. His career-long focus on data and analytics informs

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AM

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AMIntroduction Artificial intelligence (AI) is evolving to understand not just words, but also emotions, responding with a human touch. This sophisticated interaction is crucial in the rapidly advancing field of AI and natural language processing. Th

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AM

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AMIntroduction In today's data-centric world, leveraging advanced AI technologies is crucial for businesses seeking a competitive edge and enhanced efficiency. A range of powerful tools empowers data scientists, analysts, and developers to build, depl

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AM

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AMThis week's AI landscape exploded with groundbreaking releases from industry giants like OpenAI, Mistral AI, NVIDIA, DeepSeek, and Hugging Face. These new models promise increased power, affordability, and accessibility, fueled by advancements in tr

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AM

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AMBut the company’s Android app, which offers not only search capabilities but also acts as an AI assistant, is riddled with a host of security issues that could expose its users to data theft, account takeovers and impersonation attacks from malicious

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AM

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AMYou can look at what’s happening in conferences and at trade shows. You can ask engineers what they’re doing, or consult with a CEO. Everywhere you look, things are changing at breakneck speed. Engineers, and Non-Engineers What’s the difference be

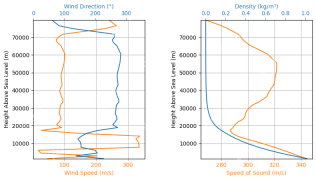

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AM

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AMSimulate Rocket Launches with RocketPy: A Comprehensive Guide This article guides you through simulating high-power rocket launches using RocketPy, a powerful Python library. We'll cover everything from defining rocket components to analyzing simula

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Dreamweaver Mac version

Visual web development tools

WebStorm Mac version

Useful JavaScript development tools

Zend Studio 13.0.1

Powerful PHP integrated development environment