How smart technology is revolutionizing the way supply chains operate

Supply chain management plays a vital role in the success of any business. Businesses continue to seek innovative ways to optimize supply chains, reduce operating costs and improve overall efficiency.

This is where the Internet of Things (IoT) and smart technology intervene, completely changing the field of supply chain management

The role of the Internet of Things in supply chain management

The Internet of Things is an interconnected network of physical devices, vehicles, buildings and other objects embedded with sensors, software and network connections that enable them to collect and exchange data. When applied to supply chain operations, IoT can revolutionize how companies manage logistics and distribution processes

1. Real-time tracking and visibility:

In the context of supply chain management, real-time tracking and visibility is a game changer. IoT devices, such as GPS sensors and RFID tags, provide a continuous flow of data, enabling entrepreneurs to monitor their goods at every stage of the supply chain journey. This means it can pinpoint the exact location of a product, monitor its condition, and track its movement from manufacturer to distributor to retailer.

The benefits are twofold. This visibility significantly reduces the risk of theft and loss, as any anomalies or deviations from the planned route can immediately trigger an alert. Second, this provides valuable insights into the overall efficiency of the supply chain. By analyzing data on delivery times, shipping routes and storage conditions, entrepreneurs can identify areas for improvement, optimize routes and ensure goods reach their destination faster and better.

2. Inventory management:

IoT sensors can automate inventory management with unprecedented accuracy and efficiency. These sensors can monitor inventory levels in real time and send automatic alerts when inventory is low or when a product is about to expire. This proactive approach to inventory management has many advantages. It prevents stock-outs and ensures businesses never run out of essential supplies, which is especially important for just-in-time manufacturing processes. At the same time, it helps reduce excess inventory, which ties up money and storage space. Ultimately, this level of control not only optimizes storage space, but also improves cash flow management by reducing excess inventory costs

3. Predictive Maintenance:In the IoT ecosystem, smart technology can predict when machines and equipment are likely to malfunction. IoT sensors on machines can continuously monitor their performance, collecting data on factors such as temperature, vibration and energy consumption. By analyzing this data, predictive maintenance algorithms can identify patterns in machines that deviate from normal operating conditions, signaling potential failures.

This predictive capability will be a game changer for supply chain operations. Businesses can proactively address maintenance needs rather than relying on planned maintenance that is costly and results in unnecessary downtime. This minimizes downtime, reduces repair costs, and ensures smooth operation. Essentially, it makes the supply chain run like a well-oiled machine.

4. Reduce costs: Supply chains that support the Internet of Things are inherently more efficient. Real-time data provided by IoT devices allows businesses to quickly identify bottlenecks and inefficiencies. For example, if goods are persistently delayed at a particular warehouse or a delivery route is suboptimal, these issues can be resolved promptly.

By optimizing processes and streamlining operations, companies can significantly reduce costs in all aspects of the supply chain, including transportation, warehousing and labor. For example, companies can minimize fuel consumption by optimizing transportation routes; reduce warehousing costs by better managing inventory levels; and increase labor productivity by automating routine tasks. This cost reduction not only improves profitability but also enables businesses to remain competitive in a rapidly changing market.

The power of data analysisThe Internet of Things will generate large amounts of data, but its true potential is unlocked through data analysis. Entrepreneurs can use this data to gain insights into consumer behavior, demand patterns and supply chain performance. By leveraging advanced analytics tools and machine learning algorithms, businesses can make data-driven decisions that enhance competitiveness.

Intelligent technologies beyond the Internet of ThingsIn addition to the Internet of Things, several other intelligent technologies are also making waves in the field of supply chain management:

1. Blockchain: The application of blockchain technology in supply chain management is completely changing the way the entire supply chain is done. It enables reliability in the supply chain journey by providing secure, transparent product and transaction tracking. Its working principle is as follows:

- Secure and Immutable Recording: Every transaction or movement of a product is recorded in a secure and immutable blockchain ledger. This means that once the data is entered, it cannot be changed or tampered with. This inherent security ensures the authenticity of records and reduces the risk of fraud or deceptive behavior.

- End-to-end transparency: Blockchain provides an uninterrupted, transparent chain of custody for products. Businesses can trace the origin of each product, monitor its flow from manufacturer to distributor to retailer, and even verify its authenticity. This transparency not only reduces the risk of counterfeit goods but also increases trust among consumers.

- Smart contracts: Blockchain allows the execution of smart contracts, which are self-executing protocols with predefined rules. These contracts can automate various supply chain processes such as payments, quality checks, and compliance checks. This automation reduces administrative overhead and ensures timely fulfillment of contractual obligations.

2. Artificial Intelligence (AI):

Artificial intelligence-driven algorithms are powerful tools for optimizing supply chain processes. Here’s how artificial intelligence is changing supply chain management:

- Demand Forecasting: Artificial intelligence algorithms can analyze historical data, market trends and various external factors to accurately predict demand. This allows companies to adjust production and inventory levels accordingly, reducing the risk of overstocking or stockouts.

- Process Automation: Artificial intelligence can automate routine and repetitive tasks such as data entry, order processing, and inventory management. Not only does this reduce labor costs, it also minimizes the possibility of human error and increases overall efficiency.

- Enhance decision-making capabilities: Artificial intelligence can analyze large amounts of data in real time and make wise decisions. For example, it can optimize shipping routes based on real-time traffic data or recommend the most cost-effective suppliers. This kind of data-driven decision-making can improve the efficiency of supply chain operations.

- Personalized Customer Service: AI-powered chatbots and customer service platforms can personalize recommendations and resolve customer issues more effectively. This enhances customer experience and fosters brand loyalty.

3. Robotic Process Automation (RPA):

Robotic process automation involves the use of robots and automation technology to streamline supply chain management all aspects. Here’s how RPA can have a big impact:

- Warehouse Operations: Robots can automate tasks within the warehouse, such as picking and packing products. It works precisely and consistently, reducing the potential for errors and increasing order accuracy. This not only speeds up order fulfillment but also reduces labor costs.

- Automation of Repetitive Tasks: RPA can handle repetitive and rules-based tasks such as data entry, invoice processing, and tracking shipments. By automating these tasks, businesses can free up human resources for more strategic activities.

- Improving efficiency: RPA can run around the clock to ensure uninterrupted supply chain operations. This improves overall efficiency and shortens delivery times.

- Reduce costs: By automating routine tasks, RPA reduces labor costs, as well as potential errors that can result in additional expenses. It also optimizes resource utilization, ensuring cost-effective operations.

The above is the detailed content of How smart technology is revolutionizing the way supply chains operate. For more information, please follow other related articles on the PHP Chinese website!

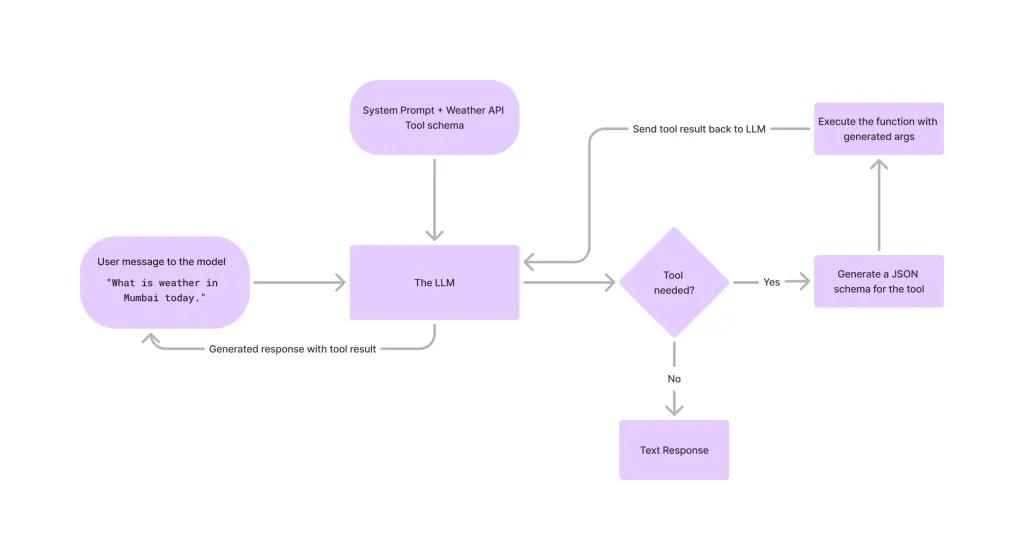

Tool Calling in LLMsApr 14, 2025 am 11:28 AM

Tool Calling in LLMsApr 14, 2025 am 11:28 AMLarge language models (LLMs) have surged in popularity, with the tool-calling feature dramatically expanding their capabilities beyond simple text generation. Now, LLMs can handle complex automation tasks such as dynamic UI creation and autonomous a

How ADHD Games, Health Tools & AI Chatbots Are Transforming Global HealthApr 14, 2025 am 11:27 AM

How ADHD Games, Health Tools & AI Chatbots Are Transforming Global HealthApr 14, 2025 am 11:27 AMCan a video game ease anxiety, build focus, or support a child with ADHD? As healthcare challenges surge globally — especially among youth — innovators are turning to an unlikely tool: video games. Now one of the world’s largest entertainment indus

UN Input On AI: Winners, Losers, And OpportunitiesApr 14, 2025 am 11:25 AM

UN Input On AI: Winners, Losers, And OpportunitiesApr 14, 2025 am 11:25 AM“History has shown that while technological progress drives economic growth, it does not on its own ensure equitable income distribution or promote inclusive human development,” writes Rebeca Grynspan, Secretary-General of UNCTAD, in the preamble.

Learning Negotiation Skills Via Generative AIApr 14, 2025 am 11:23 AM

Learning Negotiation Skills Via Generative AIApr 14, 2025 am 11:23 AMEasy-peasy, use generative AI as your negotiation tutor and sparring partner. Let’s talk about it. This analysis of an innovative AI breakthrough is part of my ongoing Forbes column coverage on the latest in AI, including identifying and explaining

TED Reveals From OpenAI, Google, Meta Heads To Court, Selfie With MyselfApr 14, 2025 am 11:22 AM

TED Reveals From OpenAI, Google, Meta Heads To Court, Selfie With MyselfApr 14, 2025 am 11:22 AMThe TED2025 Conference, held in Vancouver, wrapped its 36th edition yesterday, April 11. It featured 80 speakers from more than 60 countries, including Sam Altman, Eric Schmidt, and Palmer Luckey. TED’s theme, “humanity reimagined,” was tailor made

Joseph Stiglitz Warns Of The Looming Inequality Amid AI Monopoly PowerApr 14, 2025 am 11:21 AM

Joseph Stiglitz Warns Of The Looming Inequality Amid AI Monopoly PowerApr 14, 2025 am 11:21 AMJoseph Stiglitz is renowned economist and recipient of the Nobel Prize in Economics in 2001. Stiglitz posits that AI can worsen existing inequalities and consolidated power in the hands of a few dominant corporations, ultimately undermining economic

What is Graph Database?Apr 14, 2025 am 11:19 AM

What is Graph Database?Apr 14, 2025 am 11:19 AMGraph Databases: Revolutionizing Data Management Through Relationships As data expands and its characteristics evolve across various fields, graph databases are emerging as transformative solutions for managing interconnected data. Unlike traditional

LLM Routing: Strategies, Techniques, and Python ImplementationApr 14, 2025 am 11:14 AM

LLM Routing: Strategies, Techniques, and Python ImplementationApr 14, 2025 am 11:14 AMLarge Language Model (LLM) Routing: Optimizing Performance Through Intelligent Task Distribution The rapidly evolving landscape of LLMs presents a diverse range of models, each with unique strengths and weaknesses. Some excel at creative content gen

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment