The construction industry is currently undergoing a dramatic transformation, as digital innovation in the field is increasingly driving its direction. Robotics is one area of particular interest as it enables construction companies to implement lean practices, increase efficiency and reduce waste in the construction process.

How robots play a role in construction

One of the most prominent examples of robotization in the construction industry is the Robotic Total Station (RTS), a semi-automatic surveying tool that surveyors can use to coordinate distances, measure angles and process data. When the tool is set up, it can warn when measurement thresholds are reached and reduce the need for a two-person team to collect data. This tool, first introduced by photoelectric rangefinders in the early 1990s, is just one example of how robotics is revolutionizing the age-old construction industry.

Other recent examples of highly successful robot integration in construction include the deployment of quadruped robots, such as Boston Dynamics’ Spot robot, and the use of pre-programmed robot layout solutions. The construction robot market is expected to grow from US$2.4507 billion in 2019 to US$7.8803 billion in 2027.

As robotics becomes more popular in this field, a shift is needed to transform the construction industry from an industry based on trade skills to one that requires a combination of trade and technical skills.

Demand for Skill Proficiency

As construction robotics becomes more widely used, there is a need for workers who can manage high-level technical activities and understand the limitations of robotic tools.

An increasingly required skill among construction workers is the operation and maintenance of robots and the ability to optimize work processes, recognize the capabilities and limitations of robotic systems, and identify any differences that may affect safety and performance. Some staff will also need to be familiar with building information modeling (BIM) solutions and the data sets used to guide robots and provide contextual intelligence. Most importantly, employees need to remain flexible and able to adapt their roles to new technologies.

Developing and training employees

Improving employees’ skills in using construction robots doesn’t have to be a difficult task because not all robots are complex. It can start with instruction in basic robot operating skills, such as teaching robots to start and stop, and being able to charge and guide them. There, employees can learn to maintain the robots and plan and optimize their work, taking into account site conditions, productivity, operating times and load sizes, before moving into the more complex world of construction robots.

Once a worker has safely built their skills, they can transfer those skills to other members of the team, keeping training costs to a minimum. Once on site, the most intuitive skills can be taught immediately through demonstrations, and with longer-term training requirements, employers can help new and existing employees operate robotic systems safely and proficiently by implementing in-house training programs and self-study options.

Operation of some construction machinery requires external training and certification, and operation of some advanced robotic machinery requires similar requirements. Employers will be able to leverage AI-based simulation tools to develop capabilities in high-fidelity scenarios. For example, when more complex robotic tools like autonomous compactors, excavators and bulldozers enter the market, certification may be required, and simulation training can help employees get used to operating this machinery.

Simulation tools are a very versatile training method that can be used to teach workers a wide range of skills from bricklaying robots to 3D printing and monitoring. In simulated environments, workers can test cognition, localization, perception and sensor combinations in real-life scenarios. As workers become more proficient in using these tools, simulation systems can be adapted to replicate more dangerous and unwieldy conditions. Through this approach, workers can safely and effectively gain experience driving in complex and hazardous scenarios such as weather conditions, coordinating mixed and complex robot fleets, and planning and optimizing site conditions

Adapt to Industry

Construction robotics is a field of rapid innovation and development. By upskilling their employees, construction companies are able to develop more competitive teams that stay at the forefront of the industry, and encourage the organization to remain adaptable to change and adapt to new industry developments, allowing the company to grow with the industry as a whole. Additionally, companies can leverage the construction industry’s technological transformation to attract the top technical talent needed for the digital future

As the world shifts to digital, the construction industry is no exception. The only option for today’s construction companies is to start considering digital transformation and upskilling options now or risk being forgotten.

The above is the detailed content of How robotics heralds a new era for construction. For more information, please follow other related articles on the PHP Chinese website!

What is Graph of Thought in Prompt EngineeringApr 13, 2025 am 11:53 AM

What is Graph of Thought in Prompt EngineeringApr 13, 2025 am 11:53 AMIntroduction In prompt engineering, “Graph of Thought” refers to a novel approach that uses graph theory to structure and guide AI’s reasoning process. Unlike traditional methods, which often involve linear s

Optimize Your Organisation's Email Marketing with GenAI AgentsApr 13, 2025 am 11:44 AM

Optimize Your Organisation's Email Marketing with GenAI AgentsApr 13, 2025 am 11:44 AMIntroduction Congratulations! You run a successful business. Through your web pages, social media campaigns, webinars, conferences, free resources, and other sources, you collect 5000 email IDs daily. The next obvious step is

Real-Time App Performance Monitoring with Apache PinotApr 13, 2025 am 11:40 AM

Real-Time App Performance Monitoring with Apache PinotApr 13, 2025 am 11:40 AMIntroduction In today’s fast-paced software development environment, ensuring optimal application performance is crucial. Monitoring real-time metrics such as response times, error rates, and resource utilization can help main

ChatGPT Hits 1 Billion Users? 'Doubled In Just Weeks' Says OpenAI CEOApr 13, 2025 am 11:23 AM

ChatGPT Hits 1 Billion Users? 'Doubled In Just Weeks' Says OpenAI CEOApr 13, 2025 am 11:23 AM“How many users do you have?” he prodded. “I think the last time we said was 500 million weekly actives, and it is growing very rapidly,” replied Altman. “You told me that it like doubled in just a few weeks,” Anderson continued. “I said that priv

Pixtral-12B: Mistral AI's First Multimodal Model - Analytics VidhyaApr 13, 2025 am 11:20 AM

Pixtral-12B: Mistral AI's First Multimodal Model - Analytics VidhyaApr 13, 2025 am 11:20 AMIntroduction Mistral has released its very first multimodal model, namely the Pixtral-12B-2409. This model is built upon Mistral’s 12 Billion parameter, Nemo 12B. What sets this model apart? It can now take both images and tex

Agentic Frameworks for Generative AI Applications - Analytics VidhyaApr 13, 2025 am 11:13 AM

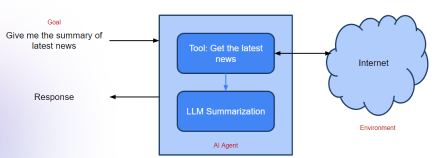

Agentic Frameworks for Generative AI Applications - Analytics VidhyaApr 13, 2025 am 11:13 AMImagine having an AI-powered assistant that not only responds to your queries but also autonomously gathers information, executes tasks, and even handles multiple types of data—text, images, and code. Sounds futuristic? In this a

Applications of Generative AI in the Financial SectorApr 13, 2025 am 11:12 AM

Applications of Generative AI in the Financial SectorApr 13, 2025 am 11:12 AMIntroduction The finance industry is the cornerstone of any country’s development, as it drives economic growth by facilitating efficient transactions and credit availability. The ease with which transactions occur and credit

Guide to Online Learning and Passive-Aggressive AlgorithmsApr 13, 2025 am 11:09 AM

Guide to Online Learning and Passive-Aggressive AlgorithmsApr 13, 2025 am 11:09 AMIntroduction Data is being generated at an unprecedented rate from sources such as social media, financial transactions, and e-commerce platforms. Handling this continuous stream of information is a challenge, but it offers an

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

SublimeText3 Linux new version

SublimeText3 Linux latest version

SublimeText3 Chinese version

Chinese version, very easy to use