Supply chain performs a series of actions, from product design to sourcing, manufacturing, distribution, delivery and customer service. Devavrat Bapat, director of AI/ML data products at Cisco, said: “At every point, there are huge opportunities for AI and ML.” This is because contemporary AI is already very good at what is needed for supply chain management. Two things. The first is forecasting, where AI is used to predict downstream demand or upstream shortages. Additionally, algorithms can detect one or more events that they believe are precursors to failure and then alert assembly line operators before production quality deteriorates.

The second is inspection, where AI is used to detect problems in manufacturing The problem. It can also be used to certify materials and components and track them throughout the supply chain

Ultimately, AI will optimize the supply chain to meet the needs of specific customers in any given situation. While enabling technologies already exist, a challenge remains in requiring a level of data sharing that is difficult to achieve in current supply chains. At the same time, many companies are still reaping the benefits of improved forecasting and inspection USD, with more than 41,000 employees and more than 200 factories worldwide. The company, which focuses primarily on food and health care packaging, holds the majority of the market share. "We manufacture one-third of the products in your refrigerator," said Joel Lanchin, the company's global chief information officer. Packaging.” Amcor’s manufacturing challenges relate to accurately predicting and adapting to changing demand. In the food supply chain world, orders are often modified based on changes in demand. For example, in hot weather, people drink more Gatorade, which could cause a sudden surge in demand, so demand for bottles could increase by 10 to 15 percent. The same goes for other types of products. There may suddenly be more fish in the ocean, increasing the need for packaging to accommodate more fish. "Even if we try to predict, it's very difficult because we don't always know what our customers want ahead of time," Lanchin said. The other end of the supply chain faces similar challenges. If Amcor can't accurately predict shortages, it can't stockpile raw materials in advance. What's more, the company needs to predict price changes so that it can buy more at a lower price before prices rise, or buy less if a drop looks like it's about to drop. Two years ago, Amcor began piloting EazyML, a platform that helps optimize customer demand and supply-side forecasting. They trained the tool using three years of data from the ERP to look for fluctuation patterns. The system attempts to find categories of changes, and which events are associated with different kinds of changes. For example, it examines seasonal fluctuations and whether two or more types of changes occur at the same time, or whether they are mutually exclusive. Lanchin said: "The preliminary results we obtained are very encouraging, and by far. Exceeded our expectations." If you can predict changes, you can better predict your raw material needs and replenish them in advance if necessary

This comes as no surprise to Bapat. Representation prediction is an area where artificial intelligence is significantly improving. “In the past, many businesses relied on consensus forecasts, weighting the opinions of different experts to arrive at an average forecast,” he said. He also noted: “Research shows that statistical forecasting methods, which use statistical techniques to extrapolate from historical data, consistently outperform consensus. methods. Even machine intelligence does a better job at prediction. But the key is making sure you use the right data."

CHECK

Another example of how AI is being used can be found at Intel, at There, several chips are printed on a wafer using photolithography. Those closest to the center of the wafer tend to have the best power performance curves. Those closer to the outer ring tend to suffer from reduced performance, although they are still reliable. Intel has a quality threshold against which chips should be kept or thrown away. Having humans inspect the wafers would be a time-consuming and glitch-filled process.

Greg Lavender, senior vice president and chief technology officer at Intel, said: "We use artificial intelligence to select high-quality chips so that they can be produced more quickly and brought to market to provide better Quality.” Of course, this is just one of the things we do with artificial intelligence. I have hundreds of AI software engineers reporting to me. Some of the work they do is used for inspection and testing in our factories, but sometimes the AI they develop is also used internally to deliver our products without necessarily being known to people

A case in point is how Intel helps their OEM customers test malware by providing software tools. One of these tools is Intel Threat Detection Technology, which runs on Intel laptops. When executing code in Windows, the Intel code examines the flow of instructions in the CPU. Utilizing an adaptive learning signature algorithm, it looks for anomalies in the code that match malware signatures. Once a match is found, the tool intercepts or blocks the malware and alerts Windows Defender of device infections. "Threat detection technology is built into all of our customer CPUs," Lavender said. These infections are delivered through the provisioning Chains creep in - when the final product is put together, the only way to find them is with this tool. We've been offering this and other AI tools for the past few years, but now with all the talk about large language models, more people are talking about it.

Inspections are an important part of supply chain management, according to Cisco's Bapat. Inspection becomes easier if the right steps are taken during the product design phase. "If you embed in the product design process instrumentation that can generate data to help monitor flow, you can save a lot of costs," he said. "If you consider the material costs and labor burden costs of any product, you'll find that they are very high." The burden mainly includes product quality and supervision and management costs. Today, artificial intelligence is already helping to minimize these costs arrival. Bapat learned an important lesson from when he was designing one of his best AI algorithms. It took nine months to develop and deploy—and ultimately, it still took a surprisingly long time to get it working. Thinking back on what went wrong, he realized that no matter how good the technology was, it wouldn't produce the desired results if he didn't first take the time to understand who the end customers were and how they planned to use the application. He also noted that while they often have the loudest voices, senior management are not the end customers.

He said: "Since then, I have always emphasized that whether it involves sales or supply chain management, I always start with a good understanding of the basic business." "Once I have a good understanding of this requirement With a solid understanding, I will go back to the field of data and AI.”

Bapat believes this concept should be applied to supply chain management: “If you really focus on the end consumer, AI can and targeting consumers and their environment to help. Then, as you work your way back through the supply chain, consider the different costs: labor, production, taxes, inventory, and optimize them together

him Adding that once the supply chain is optimized for the process, you can start installing and executing predictive quality and maintenance. From that point on, you can go back to the procurement side of supply management.

He said: " This supports the view that suppliers are partners, not adversaries. ”

So the nature of the supply chain, which is made up of at least three independent companies that don’t share data, is a long-standing challenge. First, these companies may have one or more partners in the line of business Competition. Second, they may be part of competing supply chains. Third, they retain information to increase their strength at the bargaining table.

The current generation of artificial intelligence can optimize supply chains and even tailor Customization, delivering the right product to the right customer at the right price. However, achieving this requires a level of data sharing that few companies are ready for. Bapat said: “What’s missing are technologies that allow businesses to share parts of their data with full confidence without them revealing too much. “It will take us another five to 10 years to achieve this goal. ”

The above is the detailed content of AI has already made significant achievements in supply chain management. For more information, please follow other related articles on the PHP Chinese website!

Personal Hacking Will Be A Pretty Fierce BearMay 11, 2025 am 11:09 AM

Personal Hacking Will Be A Pretty Fierce BearMay 11, 2025 am 11:09 AMCyberattacks are evolving. Gone are the days of generic phishing emails. The future of cybercrime is hyper-personalized, leveraging readily available online data and AI to craft highly targeted attacks. Imagine a scammer who knows your job, your f

Pope Leo XIV Reveals How AI Influenced His Name ChoiceMay 11, 2025 am 11:07 AM

Pope Leo XIV Reveals How AI Influenced His Name ChoiceMay 11, 2025 am 11:07 AMIn his inaugural address to the College of Cardinals, Chicago-born Robert Francis Prevost, the newly elected Pope Leo XIV, discussed the influence of his namesake, Pope Leo XIII, whose papacy (1878-1903) coincided with the dawn of the automobile and

FastAPI-MCP Tutorial for Beginners and Experts - Analytics VidhyaMay 11, 2025 am 10:56 AM

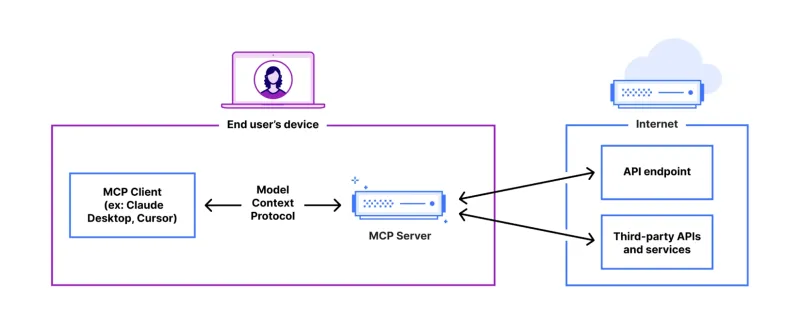

FastAPI-MCP Tutorial for Beginners and Experts - Analytics VidhyaMay 11, 2025 am 10:56 AMThis tutorial demonstrates how to integrate your Large Language Model (LLM) with external tools using the Model Context Protocol (MCP) and FastAPI. We'll build a simple web application using FastAPI and convert it into an MCP server, enabling your L

Dia-1.6B TTS : Best Text-to-Dialogue Generation Model - Analytics VidhyaMay 11, 2025 am 10:27 AM

Dia-1.6B TTS : Best Text-to-Dialogue Generation Model - Analytics VidhyaMay 11, 2025 am 10:27 AMExplore Dia-1.6B: A groundbreaking text-to-speech model developed by two undergraduates with zero funding! This 1.6 billion parameter model generates remarkably realistic speech, including nonverbal cues like laughter and sneezes. This article guide

3 Ways AI Can Make Mentorship More Meaningful Than EverMay 10, 2025 am 11:17 AM

3 Ways AI Can Make Mentorship More Meaningful Than EverMay 10, 2025 am 11:17 AMI wholeheartedly agree. My success is inextricably linked to the guidance of my mentors. Their insights, particularly regarding business management, formed the bedrock of my beliefs and practices. This experience underscores my commitment to mentor

AI Unearths New Potential In The Mining IndustryMay 10, 2025 am 11:16 AM

AI Unearths New Potential In The Mining IndustryMay 10, 2025 am 11:16 AMAI Enhanced Mining Equipment The mining operation environment is harsh and dangerous. Artificial intelligence systems help improve overall efficiency and security by removing humans from the most dangerous environments and enhancing human capabilities. Artificial intelligence is increasingly used to power autonomous trucks, drills and loaders used in mining operations. These AI-powered vehicles can operate accurately in hazardous environments, thereby increasing safety and productivity. Some companies have developed autonomous mining vehicles for large-scale mining operations. Equipment operating in challenging environments requires ongoing maintenance. However, maintenance can keep critical devices offline and consume resources. More precise maintenance means increased uptime for expensive and necessary equipment and significant cost savings. AI-driven

Why AI Agents Will Trigger The Biggest Workplace Revolution In 25 YearsMay 10, 2025 am 11:15 AM

Why AI Agents Will Trigger The Biggest Workplace Revolution In 25 YearsMay 10, 2025 am 11:15 AMMarc Benioff, Salesforce CEO, predicts a monumental workplace revolution driven by AI agents, a transformation already underway within Salesforce and its client base. He envisions a shift from traditional markets to a vastly larger market focused on

AI HR Is Going To Rock Our Worlds As AI Adoption SoarsMay 10, 2025 am 11:14 AM

AI HR Is Going To Rock Our Worlds As AI Adoption SoarsMay 10, 2025 am 11:14 AMThe Rise of AI in HR: Navigating a Workforce with Robot Colleagues The integration of AI into human resources (HR) is no longer a futuristic concept; it's rapidly becoming the new reality. This shift impacts both HR professionals and employees, dem

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

SublimeText3 Linux new version

SublimeText3 Linux latest version

WebStorm Mac version

Useful JavaScript development tools