Home >Technology peripherals >AI >'Robots' are implemented in industrial manufacturing, and craftsmen 'have certificates to work'

'Robots' are implemented in industrial manufacturing, and craftsmen 'have certificates to work'

- WBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBOYWBforward

- 2023-09-07 19:09:021324browse

In the process of intelligent upgrading of factory production, quality inspection is one of the links empowered by AI.

Traditional quality inspection relies on the human eye and years of experience to detect defects, which is inefficient and prone to problems such as missed inspections and false inspections. As labor costs rise, there are fewer and fewer "old masters" who understand quality inspection, and young people are generally unwilling to engage in quality inspection work

As a result, cameras equipped with AI vision algorithms have become the core of replacing naked eye quality inspection. More and more factories have begun to introduce AI quality inspection to transform production lines and improve production efficiency. Compared with manual quality inspection, the advantage of AI quality inspection is that it can conduct inspections 24 hours a day, improving efficiency and quality.

Rewritten content: The current common practice is that the factory will modify the production line and install an artificial intelligence quality inspection solution, which usually consists of cameras and systems, and can be put into use once the deployment is completed. However, there are some problems with this solution. First, the solution is highly customized and the transformation cycle is long. Secondly, once deployed, it is difficult to reuse the solution to other production lines and lacks flexibility

For enterprises, the direct and hidden costs of deploying a set of AI quality inspections are very high. Especially for the vast number of small and medium-sized enterprises, this high-cost solution is not suitable. The market is in urgent need of solutions that can achieve high quality, high efficiency but low deployment cost.

Weiyi Intelligent Manufacturing has launched a digital worker called "Gongxiaojiang|AI Digital Quality Inspector", which can exactly solve the pain points of enterprises in quality inspection transformation

Weiyi Intelligent Manufacturing "Artisan | AI Digital Quality Inspector"

Three major advantages of "Gongxiaojiang": flexibility, professionalism and efficiency

As an AI digital worker, the flexibility of "Xiaojiang" benefits from the intelligent control of the robot.

Human arms are very flexible and can complete many movements. However, it is very technically difficult to achieve a human-like degree of freedom for a robot arm.

The principle of "Gongxiaojiang" is to use algorithm planning and simulation modeling to allow the robot to automatically find the shooting point and angle of the target object according to different imaging conditions. After the target task is established, "Gongxiaojiang" then accurately controls the movement of each axis of the robotic arm and combines it with a self-developed path planning algorithm to calculate and generate the optimal motion trajectory.

This method can not only increase the degree of freedom of the robotic arm, but also avoid the previous dilemma of requiring constant manual debugging, thereby reducing labor costs

"Workers" can not only know "where to go" and "how to get to the destination", but can also "move freely" without having to be fixed on the production line like traditional solutions. Therefore, "Gongxiaojiang" can be said to be suitable for multiple scenarios and solve the pain points of flexible quality inspection for enterprises. Moreover, in the process of planning the path, you can use the obstacle avoidance algorithm to run faster, more stably, and safer.

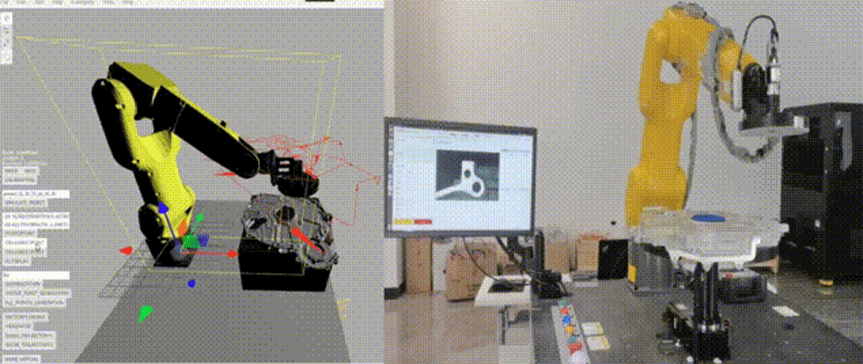

Synchronous application of motion trajectories in the simulation environment in real scenes

Professional is another core competitiveness of "Gongxiaojiang", in addition to flexibility

In the field of quality inspection, robotic arms, like humans, need to see objects before they can perform corresponding actions. Although the robotic arm can complete many tasks, visual perception is its primary condition

Traditional industrial cameras, in order to capture defects and improve detection accuracy, require optical engineers to repeatedly adjust the light source at the project site, which is not only time-consuming and labor-intensive, but also requires additional debugging costs.

"Gongxiaojiang" is based on Weiyi Intelligent Manufacturing's self-developed online optical adjustment system, which can automatically generate the best photo-taking points and angles, and adaptively optimize the optical parameters to ensure high-definition picture taking at each point without any problem. Every little flaw is missed. While manually correcting the algorithm debugging results, the algorithm is also constantly learning from people's debugging experience and quickly becoming an "optical expert". The time is shortened to a few hours, making flexible tangent possible.

In real-life scenarios, the simultaneous application of optical solutions in the simulation environment

Before the "worker" officially takes up the job, he will put the robot's intelligent control, optical point and angle design, and automatically generated trajectory paths in the simulation environment to verify them one by one. Through a full digital twin that combines virtuality and reality, optimal work performance is ensured online before being distributed to actual work; related regression tests will also reproduce and repair emergencies through cloud simulation scenarios, remotely and comprehensively Solve various on-site problems.

In addition to flexibility and professionalism, "craftsman" is also very efficient.

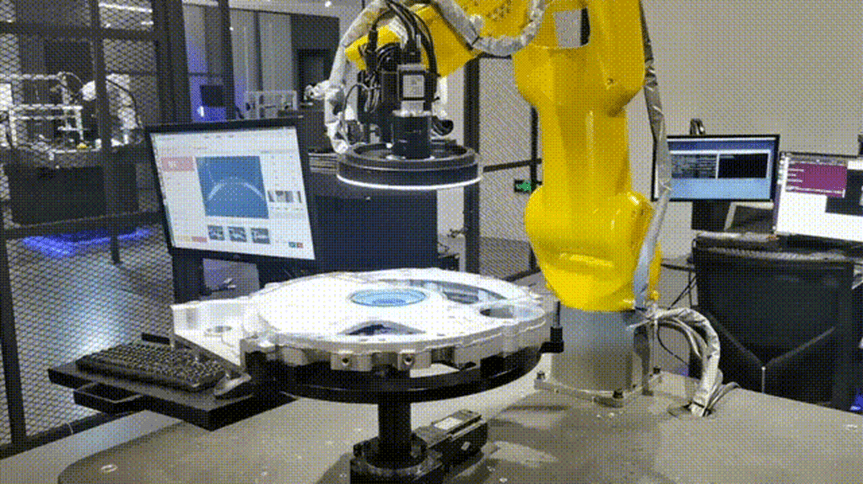

According to information, "Gongxiaojiang" is equipped with high-speed flying imaging technology, the terminal linear speed can reach 1000mm/s, and the CT shooting of each point only takes 0.3 seconds

Through the cooperation of robot intelligent control and imaging modules, "Gongxiaojiang"'s arm can accurately image the target point while moving at high speed, and the repetition error is less than 2 pixels, with high efficiency and high quality. Features

High-speed flying imaging technology

Two major features of "Gongxiaojiang": short deployment cycle and full-cycle management

For solution providers, the flexible production needs of enterprises force solution providers to make solutions more flexible and convenient. In addition to products that can adapt to different quality inspection scenarios, the deployment cycle must also be shortened so that enterprises can It can be "plug and play" like charging a mobile phone.

Traditional human quality inspection requires a long training cycle, while many AI quality inspection solutions on the market rely on a large amount of defect data and often require stopping the production line for modification. This solution is not only costly, but also has a very short deployment period. long.

Based on its own AI capabilities, Weiyi Intelligent Manufacturing has completed the accumulation of tens of millions of defect data and formed a large number of pre-trained models. With the support of its self-developed Tri-vision visual algorithm and unique model training method, the algorithm model greatly reduces the demand for sample size and greatly compresses the model training and online time. For example, single defect detection only requires 20 to 50 samples, and obvious defects can be detected in 0 samples. "Gongxiaojiang" can already train for a week and then put it into use immediately.

Compared with traditional quality inspection solutions, the sample demand of "Hong Kong Xiaojiang" has been reduced by 70%, and the production cycle of the entire project has been shortened by nearly 90%. And after taking up the job, the "workers" can quickly complete the work targets according to the quality standards of the production line.

In addition to the identity of digital workers, "workers" also have two other identities: quality manager and quality analyst.

Nowadays, in the daily production management of enterprises, the value of quality inspection is not limited to the last step of product quality inspection, but lies in the full-cycle management of the entire quality inspection, including prevention, detection, traceability, optimization, etc. Front-end and back-end links. Only in this way can costs be reduced and efficiency improved from the perspective of the entire process.

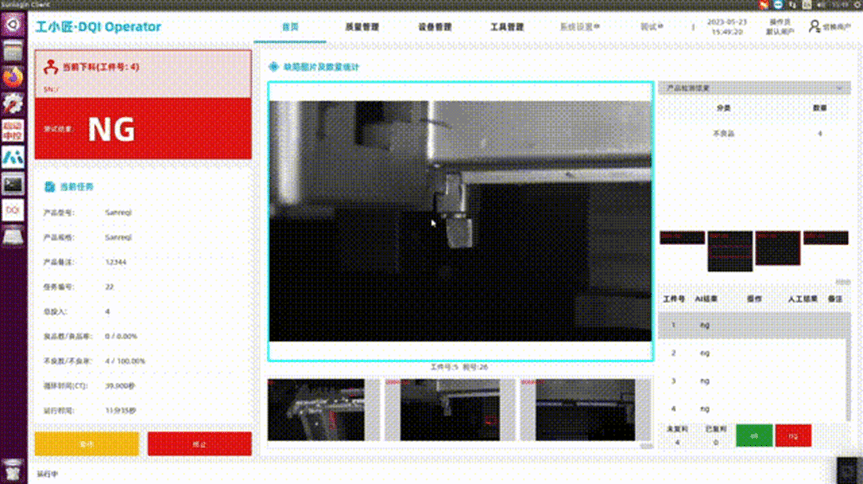

"Gongxiaojiang" can not only obtain comprehensive quality data through Weiyi's self-developed DQI software system, but also further complete the modeling and analysis of quality data to help enterprises achieve quality risk warning, quality defect statistics, and quality problem positioning and analysis.

DQI Software System—Quality Analysis Management

On the one hand, enterprises can use craftsmen to improve quality inspection efficiency and quality, and on the other hand, they can also do quality management well. Moreover, based on data analysis, "Gongxiaojiang" can perform process management based on the specific conditions of the production line, conduct retrospective review, and carry out "prevention." In other words, enterprises using "craftsmen" can optimize the cost of the entire quality inspection process and improve enterprise production efficiency.

At present, "little craftsmen" can already enter various factories, such as new energy vehicles, digital 3C, small household appliances factories, porcelain workshops, etc., and the identity of "digital workers" "holds a certificate to work ”, providing quality inspection services to enterprises.

Summarize

Quality inspection is an important part of production, and its importance to products is self-evident.

Among the many customized and long-cycle solutions, Weiyi Intelligent Manufacturing "Gongxiaojiang" has developed an easy-to-deploy and cost-saving path, which is more suitable for the flexible production needs of small and medium-sized enterprises.

In the future, "gongxiaojiang" will appear as digital workers in various quality inspection scenarios, empowering enterprises, and helping my country's industries realize intelligent transformation and upgrading

The above is the detailed content of 'Robots' are implemented in industrial manufacturing, and craftsmen 'have certificates to work'. For more information, please follow other related articles on the PHP Chinese website!

Related articles

See more- Learn to use Python to implement WeChat robot functions in eight hours (detailed explanation with pictures and text)

- Let's talk about how nodejs implements DingTalk single chat robot (step sharing)

- What are the characteristics of collaborative robots?

- Taking stock of the seven best robotics engineering schools in the world

- What are the main sensors of the robot? Introduction to the main sensors of the robot